OPTIMA XPC RAINSCREEN

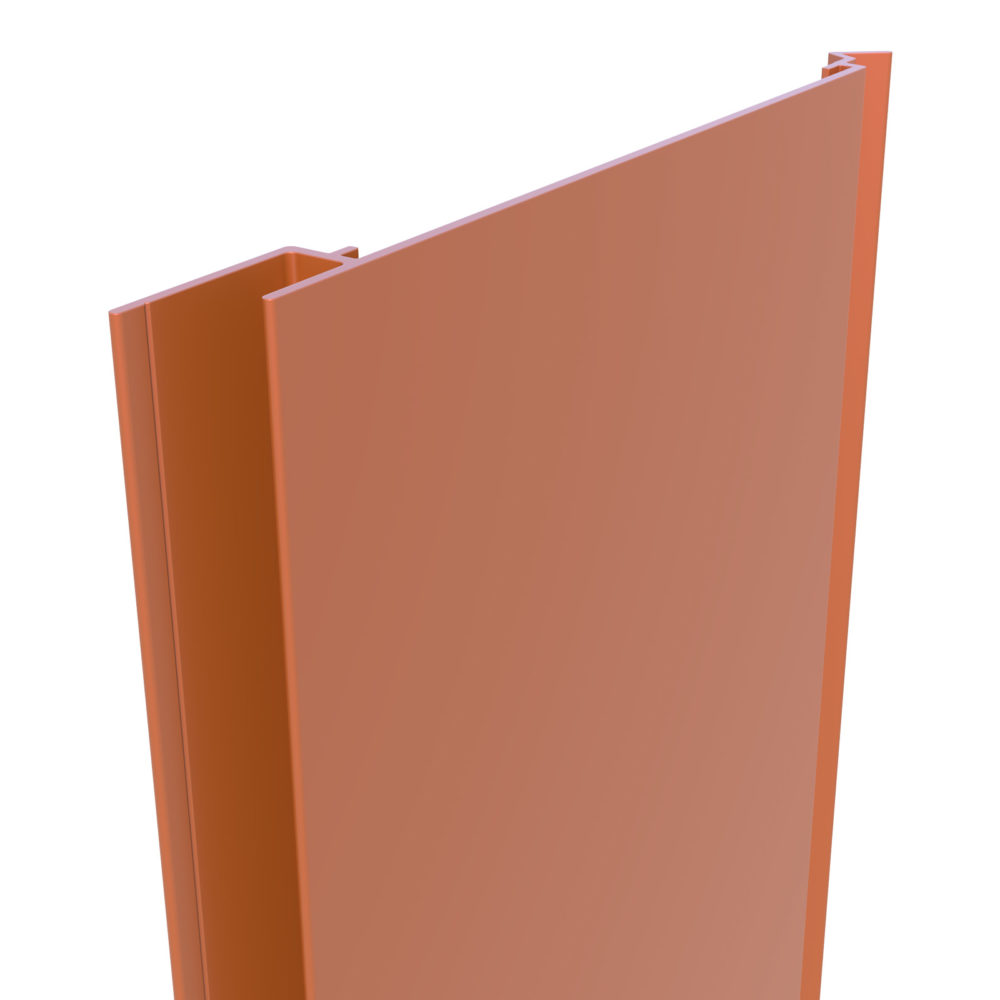

An aluminium extrusion plank rainscreen system has set flat face modules of 150mm, 190mm. 200mm, 225mm, and 250mm as well as a 150mm module castellated extruded aluminium plank rainscreen.

This product can be used as a weathered screen introducing ventilation at the base of a wall and at the top. Some ventilation can be introduced at the cross-plank joints by leaving a gap with the support structure behind creating a baffle.

View an interactive 3D model, animation, substructure information and panel sizes using the buttons below. If you have any comments or questions please get in touch and an expert will get back to you as soon as possible.

For a fully immersive virtual reality experience, SOTECHVR allows users to examine complete 3D models of our Optima range, change the rainscreen system to a material/finish of your choice, learn more about fire safety and rainscreen testing.

BENEFITS OF THE OPTIMA XPC SYSTEM

- Due to the inherent strength of an aluminium extrusion, this product only needs to be 15mm thick, which makes it ideal for refurbishments where space is limited due to adjacent boundary restrictions.

- All planks can interlock with each other. Optima XPC lends itself to use in all areas – including low-level vulnerable areas through superior deflection and impact resistance.

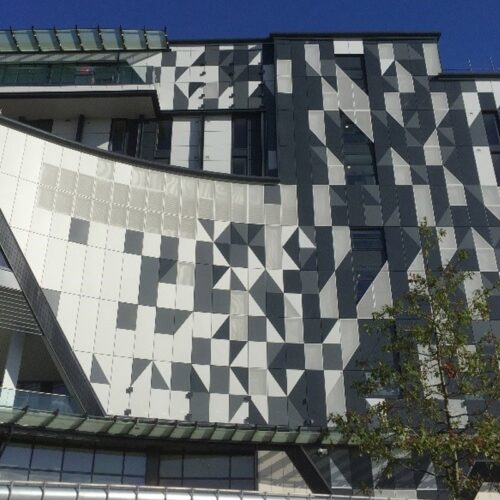

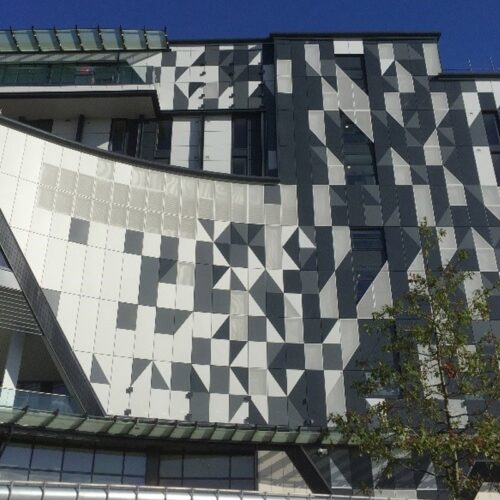

- All commercial finishes may be incorporated on one elevation to create an almost limitless effect of colours and shapes.

- Full range of Euroclass A1 and A2 – s1,d0 panel materials from 2mm – 4mm.

- Mechanical fixing methods and no use of adhesives, providing true A1 and A2 cladding systems.

- The XPC is secretly fixed onto an extruded aluminium support framework horizontally, vertically or diagonally.

- The aluminium planks are connected by a simple interlocking male/female joint, which offers either a recessed or hairline appearance.

- The system has been independently tested and certified to meet CWCT rigorous specification for rainscreen cladding.

- NBS specifications available tailored to your project.

- Drained and ventilated system creates a weather shield in front of a primary structure

ANODISED ALUMINIUM

Anodising is an A1 non-combustible finish. It is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts.

Due to the nature of the anodising process and the tight quality controls on both the aluminium and the surface treatment, anodising has a homogeneous (matching & consistent) appearance.

Colours, textures and patterns can be incorporated in the anodic film, enhancing the natural metallic appearance without affecting the total UV resistance of the rainscreen cladding.

Anodising enhances the natural qualities of aluminium further; it permits a strongly contemporary finish with incomparable corrosion and abrasion resistance.

Aluminium is exceptionally recyclable, requires minimal maintenance and has proven lifetime performance.

Polyester Powder CoatED ALUMINIUM (PPC)

PPC is an A2 limited combustibility finish.

PPC is a type of dry coating, rather than a conventional liquid paint, and is applied to metal rainscreen as a free flowing, dry powder. The powder is applied to rainscreen panels electrostatically and is then cured under heat to allow it to form a ‘skin’. This electrostatic powder process means we can ensure complete coverage of the panels, even on more complex shapes.

Powder Coating can produce a much thicker coating than conventional liquid coating leaving PPC rainscreen cladding with a hard finish. This is much tougher than normal paint and its strong abrasion and corrosion resistance properties make it extremely durable and long lasting.

If you are looking for a finish to make your project stand out PPC is a great specification choice with a range of 200 standard RAL colours and a wide choice of special effects offer a great alternative to anodised aluminium and stone, natural effects and different textures can be used to add a unique touch to your project.

Learn More…

The Learning Zone plays host to innovative design workshops, CPD seminars and launch events where designers, contractors and material manufacturers can meet, evaluate and review projects and address technical issues at the very start of the design process.

We also have constructed training walls where installation teams can come and familiarise themselves with our Optima Rainscreen Systems, and products can be tried, tested and handled prior to going on site.

IF YOU’RE AN ARCHITECT/DESIGNER

There is a huge range of materials, finishes, colours and design options, offering the specifier an almost limitless choice of products, presented in a practical and convenient way designed to cut research time for the designer and provide an in-depth technical resource.

IF YOU’RE AN INSTALLER:

Experience the range of systems and choice of materials, explore technical solutions to specific problems, iron out design details and gain an understanding of scheduling requirements. All systems can be examined in detail and real-life applications can be rigorously reviewed and tested.

Peterborough University

West End Quay, London

Leicester City Football Club Training Ground

One Ashley Road, Ashley Road East

Lancaster University School of Mathematics (LUSoM)

Kelaty House, Wembley

Plot C1, English Cities Fund (ECF) – New Bailey, Salford Quays

Science, Engineering & Environment Building, Salford University

Project Vita, Nottingham

PEMC Nottingham

Nottingham College City Hub

Frederick Douglas Centre, Science Central, Newcastle

Lancaster Circus

Fulham Boys’ School

Premier Inn, Glasgow

Bournemouth Gateway Building

Discovery Quay, Salford

The Refinery, Bingley Street, Leeds

New Era Square

Unite White Rose View

Queen Street, Glasgow

Bath Court, Birmingham

Oman Air Traffic Control, Oman

The Lumen, Newcastle Helix

Leeds Beckett University, Carnegie School of Sport

Horizon Heights, Student Accommodation, Liverpool

Calico, Norton Street, Liverpool

Hilton Garden Inn, London Heathrow T2 Hotel

Queenshurt Kingston

Alto NW06 Wembley

South Shields Interchange Hub

Northshore – Hilton Stockton

Collaborative Teaching Lab, Birmingham Uni

Milton Keynes Car Park

Chaucer House, Portsmouth

White Rose Shopping Centre Leeds

Thorpe Park, Leeds

Hill Court, Pitt Street, Newcastle upon Tyne

Birmingham Children’s Hospital

Vue Cinema

Guildford Business Park

Westgate Travelodge

Aldwych House

Chrisp Street

North Shore Innovation Centre

Glaxo Smith Kline (GSK)

Glow, Bluewater Shopping Centre

Regent High School

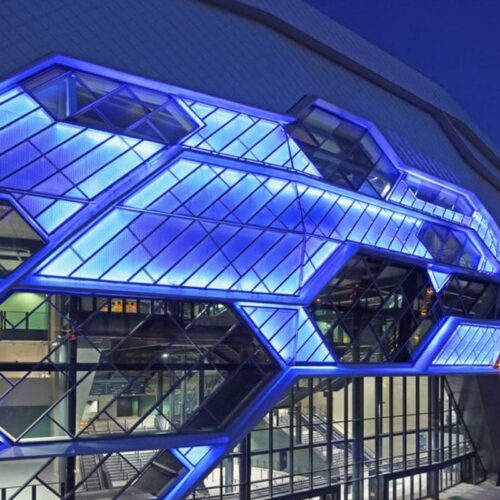

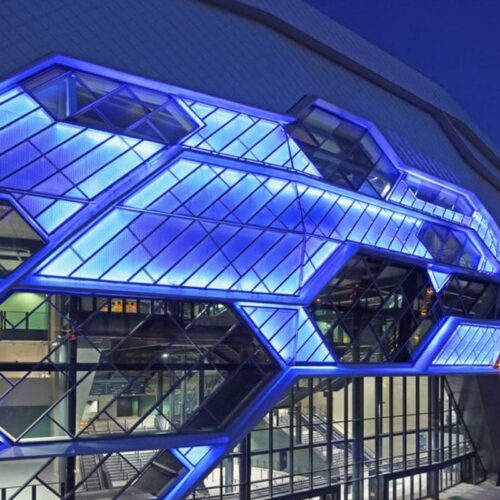

First Direct Arena

Manchester University

Manchester Air Traffic Control

Newcastle University Viewing Box

Outwood Academy

Vermillion, Rathbone Market

Silverstone University Technical College

Staffordshire University Science & Technology Centre

Westgate Cineworld

Baltic Centre for Contemporary Arts

Asda Multi Storey Car Park

Paradise Street

Park View

The Elements, Almondvale Shopping Centre Car Park

Hull Royal Infirmary

Darlington Business Growth Hub

GWQ Barratt Homes LDN

The Core, Science Central

Krispy Kreme

The View, Downing Plaza

B Sky B

NEC Resorts Development

The Foundry

Farnham Road Hospital

Apex Phase 2, University of Liverpool

Grimsby Leisure

St Vincent Plaza, Glasgow

Elephant Road

Hallam University, Charles Street

Victoria Halls

Sheffield University, Durham Road Car Park

Optic Cloak, Greenwich Energy Centre

Pullman Hotel Liverpool Waterfront

Case Study: Oakfields Community College, Middlesbrough

OPTIMA XPC CWCT TESTING

The CWCT ‘Standard for systemised building envelopes’ gives a framework for specifying building envelopes and provides a ‘Specifiers checklist’ showing information that will change from project to project.

This includes:

- Internal and external environment

- Air permeability

- Thermal performance

- Access and safety

- Design life

Tests performed:

Watertightness – dynamic

Wind resistance – serviceability

Wind resistance – safety

Soft body Impact

SOTECH Optima XPC

Certificate Number: 2010/42

Fire Test Performed at: Vinci Technology

Date test performed: July 2009

Learn More…

The Learning Zone plays host to innovative design workshops, CPD seminars and launch events where designers, contractors and material manufacturers can meet, evaluate and review projects and address technical issues at the very start of the design process.

We also have constructed training walls where installation teams can come and familiarise themselves with our Optima Rainscreen Systems, and products can be tried, tested and handled prior to going on site.

IF YOU’RE AN ARCHITECT/DESIGNER

There is a huge range of materials, finishes, colours and design options, offering the specifier an almost limitless choice of products, presented in a practical and convenient way designed to cut research time for the designer and provide an in-depth technical resource.

IF YOU’RE AN INSTALLER:

Experience the range of systems and choice of materials, explore technical solutions to specific problems, iron out design details and gain an understanding of scheduling requirements. All systems can be examined in detail and real-life applications can be rigorously reviewed and tested.

Peterborough University

West End Quay, London

Leicester City Football Club Training Ground

One Ashley Road, Ashley Road East

Lancaster University School of Mathematics (LUSoM)

Kelaty House, Wembley

Plot C1, English Cities Fund (ECF) – New Bailey, Salford Quays

Science, Engineering & Environment Building, Salford University

Project Vita, Nottingham

PEMC Nottingham

Nottingham College City Hub

Frederick Douglas Centre, Science Central, Newcastle

Lancaster Circus

Fulham Boys’ School

Premier Inn, Glasgow

Bournemouth Gateway Building

Discovery Quay, Salford

The Refinery, Bingley Street, Leeds

New Era Square

Unite White Rose View

Queen Street, Glasgow

Bath Court, Birmingham

Oman Air Traffic Control, Oman

The Lumen, Newcastle Helix

Leeds Beckett University, Carnegie School of Sport

Horizon Heights, Student Accommodation, Liverpool

Calico, Norton Street, Liverpool

Hilton Garden Inn, London Heathrow T2 Hotel

Queenshurt Kingston

Alto NW06 Wembley

South Shields Interchange Hub

Northshore – Hilton Stockton

Collaborative Teaching Lab, Birmingham Uni

Milton Keynes Car Park

Chaucer House, Portsmouth

White Rose Shopping Centre Leeds

Thorpe Park, Leeds

Hill Court, Pitt Street, Newcastle upon Tyne

Birmingham Children’s Hospital

Vue Cinema

Guildford Business Park

Westgate Travelodge

Aldwych House

Chrisp Street

North Shore Innovation Centre

Glaxo Smith Kline (GSK)

Glow, Bluewater Shopping Centre

Regent High School

First Direct Arena

Manchester University

Manchester Air Traffic Control

Newcastle University Viewing Box

Outwood Academy

Vermillion, Rathbone Market

Silverstone University Technical College

Staffordshire University Science & Technology Centre

Westgate Cineworld

Baltic Centre for Contemporary Arts

Asda Multi Storey Car Park

Paradise Street

Park View

The Elements, Almondvale Shopping Centre Car Park

Hull Royal Infirmary

Darlington Business Growth Hub

GWQ Barratt Homes LDN

The Core, Science Central

Krispy Kreme

The View, Downing Plaza

B Sky B

NEC Resorts Development

The Foundry

Farnham Road Hospital

Apex Phase 2, University of Liverpool

Grimsby Leisure

St Vincent Plaza, Glasgow

Elephant Road

Hallam University, Charles Street

Victoria Halls

Sheffield University, Durham Road Car Park

Optic Cloak, Greenwich Energy Centre

Pullman Hotel Liverpool Waterfront

Case Study: Oakfields Community College, Middlesbrough

OPTIMA XPC DOWNLOADS

PLEASE ADD WHAT YOU REQUIRE TO YOUR DOWNLOAD LIST.

Once you have added all the files you require to your download list you can gain access to them using the downloads button in the top right or bottom right of your screen. If you have any issues, comments or questions please get in touch and an expert will be in touch as soon as possible.

SOTECHVR

A NEW WAY TO VIEW OPTIMA SYSTEMS

No VR headset? No problem! SOTECHVR will automatically start a standard 3D version if no headset is detected.

For a fully immersive virtual reality experience, SOTECHVR allows users to examine complete 3D models of our Optima range, change the rainscreen system to a material/finish of your choice, learn more about fire safety and rainscreen testing.

No downloads in list yet.

No downloads in list yet.