5500m2 of Optima TFC+ has been used in the completion of the brand new Science, Engineering and Environment building on Salford University’s Peel Park campus.

As you can see from the photos, a striking colour palette has been used in the modified window interface details. Interpon’s D2525 Ostuni Y2211I, 3030 High Gloss & 7022 High Gloss in 3.0mm Aluminium 3103 Grade PPC were selected.

The unique overhang window details were created using the 20mm overlapping joint that is standard in Optima TFC+. A bespoke sharp edge detail was added to window interface locations for dramatic effect, creating a stunning visual contrast between the bright red window pods against the white vertical cladding as per the architect’s original design intent.

Sotech assembled a full-size sample rig in the factory for the client, architect, main contractor and installer to view a full scale mock-up of the final proposed solution. This ensured that any design details or install sequences were scrutinised and fully understood before the project began onsite. Sotech then created a full 3D model of the project alongside their long-term partners Metclad Contracts. This allowed both parties to identify and avoid potential issues at the design stage before panels were fabricated and delivered to site.

Testimonials:

Jamie Brown of Sotech said: “This is yet another example how close collaboration from day one, involving the full supply chain, ensures projects can be delivered on time and on budget. The very clever and intricate window interface details showcases just how versatile rainscreen cladding can be, whilst staying within the boundaries of a fully CWCT tested and accredited system.”

Naveen Sandhu at Akzo Nobel said: “Great to see this installation following an increasing trend of injecting vibrant tones into the elevation. One of a plethora of schemes in Salford and Manchester adopting our enhanced D2525 PPC technology across the envelope. Pleasure to work with the team at Sheppard Robson and delivering yet another outstanding higher education facility with Sotech.”

The SEE Building is Salford University’s brand new £65 million hub for discovery and innovation. Consisting of four stories over 15,500 sq meters, the department will house the university’s departments of Built Environment, Computer Science and Networking, Mechanical Engineering and Human & Natural Science, in addition to the university’s Morson Maker Space – an additive manufacturing and digital fabrication facility.

The building was awarded North West Regional Construction Awards and received BREEAM Excellent rating.

PROJECT DETAILS:

Project name: Science, Engineering & Environment Building, Salford University

Location: Salford

Sector: Education

Installer: Metclad

Main Contractor: Morgan Sindall

Architect: Shepphard Robson

Benefits of Optima TFC+

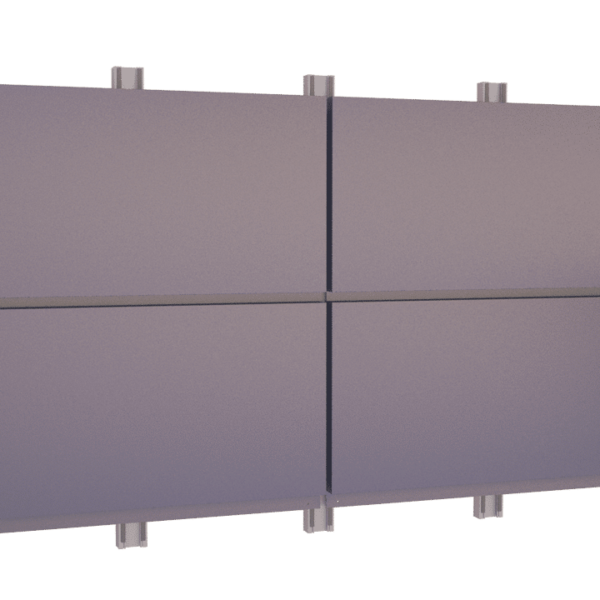

The Optima TFC+ rainscreen system has been developed as an economical alternative to a complete secret fix rainscreen cladding.

The cost effective rainscreen solution requires discreet colour match wafer head fixings in the vertical panel recesses. Superior manufacturing techniques ensure accuracy of panel’s size and form leaving even recesses and cruciform of pristine appearance.

Click here to view an interactive 3D model, animation, substructure information and panel sizes. If you have any comments or questions please get in touch and an expert will get back to you as soon as possible.

For a fully immersive virtual reality experience, SOTECHVR allows users to examine complete 3D models of our Optima range, change the rainscreen system to a material/finish of your choice, learn more about fire safety and rainscreen testing.

- The system has been independently tested and certified to meet CWCT rigorous specification for rainscreen cladding.

- This drained and ventilated system consists of a baffle-jointed series of panels

- Creates a weather shield in front of a primary structure.

- Mechanical fixing methods and no use of adhesives, providing true A1 and A2 cladding systems.

- Discreet fixings in the vertical panel recess, the engineering of the system retains the benefits of a drained and ventilated façade.

- Superior manufacturing techniques ensure there will be no build-up of metal thickness at the cruciform joint.

- Optima TFC+ is engineered to seamlessly integrate with all other building façade elements such as windows, doors and louvres.

- All fixings used in the systems are stainless steel.

- Fire tested to BS8414-2:2015, and classified to BR135 for high rise buildings.

- Full range of Euroclass A1 and A2 – s1,d0 panel materials from 2mm – 4mm

- NBS specifications available tailored to your project.

SPEAK TO AN EXPERT

If you require advice with design detail, assistance with a specification or to discuss your project in detail contact our technical department who have over 40 years’ experience in the construction industry. The team is on hand to provide knowledge and support at every stage of your project.

No downloads in list yet.

No downloads in list yet.