In celebration of Optima XPC going live on BIM we thought we’d shout about the four architectural benefits of selecting the extruded rainscreen cladding plank system in your next project.

(1) Durability

The Optima XPC Extruded Plank system was introduced into our range of rainscreen to provide our clients with something that is robust at ground level so as to minimise the impact of damage to the system and maintain the quality of the project for as long as possible. This makes the system ideal for schools, hospitals and other buildings with high foot traffic.

With its robust nature – the Optima XPC Rainscreen system is manufactured from extruded metal, which is a much stiffer alloy – XPC is an excellent alternative to the more fragile and more costly terracotta, stone and masonry cladding solutions. Combining this with an anodised finish makes the XPC the most durable product that Sotech offers.

To test this, we initially created a plank system with 200mm wide modules, using a variety of substructures, and found that it received no damage, even at a high impact level of 500 newtons. Due to the success of this original plank, we extended our range to include 150mm and 150mm castellated plank to increase the number of solutions we can offer.

(2) Economical (time and money)

Optima XPC is an economical alternative to the costlier terracotta, stone and masonry cladding.

Originally favoured due to its fireproof nature and durability, architects are turning to metal alternatives to maximise budget whilst creating a similar effect.

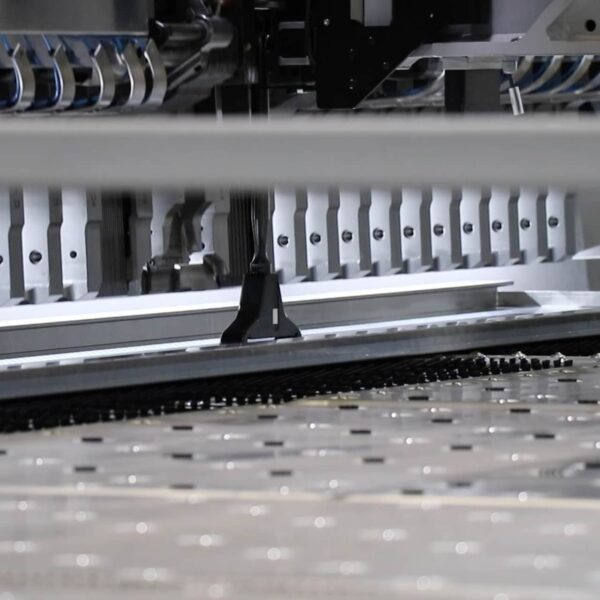

In addition to savings on the raw material and manufacturing costs, Optima XPC is faster to produce than the terracotta alternative: the system typically takes between 6-8 week to manufacture. Plus, time is saved on site due to the lightweight transportable nature of the planks, which can be manufactured in longer lengths, resulting in less joints and support rails to fix on site

The Optima XPC cladding system, provides a faster, higher, stronger and more lightweight alternative to terracotta, stone and masonry cladding systems. You can read more about this in our recent blog on the subject.

(3) Tested, accredited and approved

To ensure the highest quality of product and performance for your project our Optima XPC Rainscreen is a fully independently tested and accredited system to CWCT standards and fully compliant to NHBC requirements. We continue to test our systems year in, year out to maintain this standard and keep up with the latest industry developments.

XPC is solid aluminium and therefore non-combustible, all available finishes are Class O for surface spread of flame and the Optima XPC system has been impact tested to CWCT standards and is resistant to site knocks and drops.

(4) Extreme adaptability

A huge benefit of the Optima XPC system is that it is extremely adaptable to fit the specific requirements of each project. Because we can create different profiles and recesses for each plank, use multiple materials in one project and vary the substructures, we can bring the dimensions of the system right down to ground level and maximise its strength in areas more susceptible to damage.

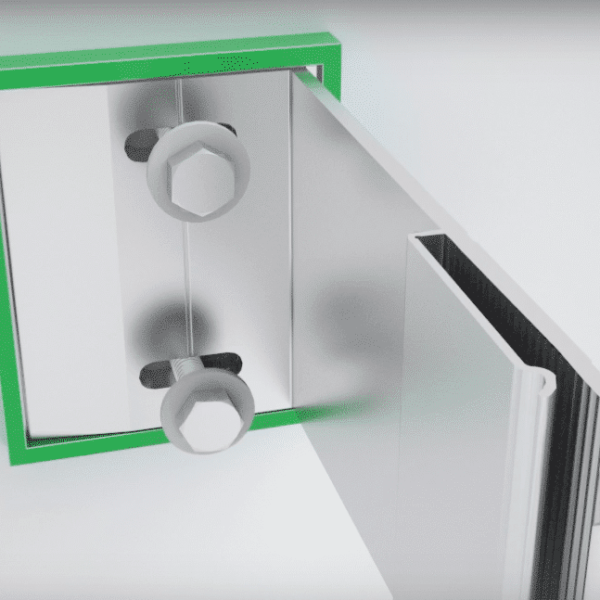

The Optima XPC rainscreen system completely interlocks, whether that’s horizontally or vertically, meaning the fixings are completely hidden.

Plus, Optima XPC is available up to 6m long and the structural strength of the material allows spans of up to 1.2m, reducing rails, brackets and fixings. All commercial finishes may be incorporated on one elevation to create an almost limitless effect of colours and shapes.

With the use of aluminium, the solution is much lighter than more traditional terracotta – system weight from as little as 10kg/m2 – making XPC easier to transport, lift and handle. The benefit? Compared to traditional systems the weight savings could reduce the building frame design.

Due to the inherent strength of extruded aluminium, this product only needs to be 15mm thick, which makes it ideal for refurbishments where space is limited due to adjacent boundary restrictions.

As the longitudinal joint is not ventilated this product can be used as a weathered screen introducing ventilation at the base of a wall and at the top or some ventilation can be introduced at the cross plank joints by leaving a gap with the support structure behind creating a baffle.

3D model of the Optima XPC Rainscreen Cladding System

Working with Sotech

Optima XPC is a complete secretly fixed extruded aluminium plank rainscreen system and has set flat face modules of 150mm, 200mm, 225mm, and 250mm as well as a 150mm module castellated extruded aluminium plank rainscreen.

To find out more about specifying Optima XPC in your next project contact our team today. We’d love to arrange a visit or call with you to discuss the best systems, materials and finishes for your individual project.

When you book a consultation with one of our technical advisors we will arrange to visit you on site, discuss your design over the phone or alternatively you’re welcome to visit our factory and training facility to see our rain screen systems, materials and finishes up close and personal.

No downloads in list yet.

No downloads in list yet.