Sotech’s Optima XTR contour extruded plank range gives architects and designers a creative licence with more extruded profiles as standard, the ability to customise profile dies to suite specific needs and the option of interlocking different profiles to achieve a unique design.

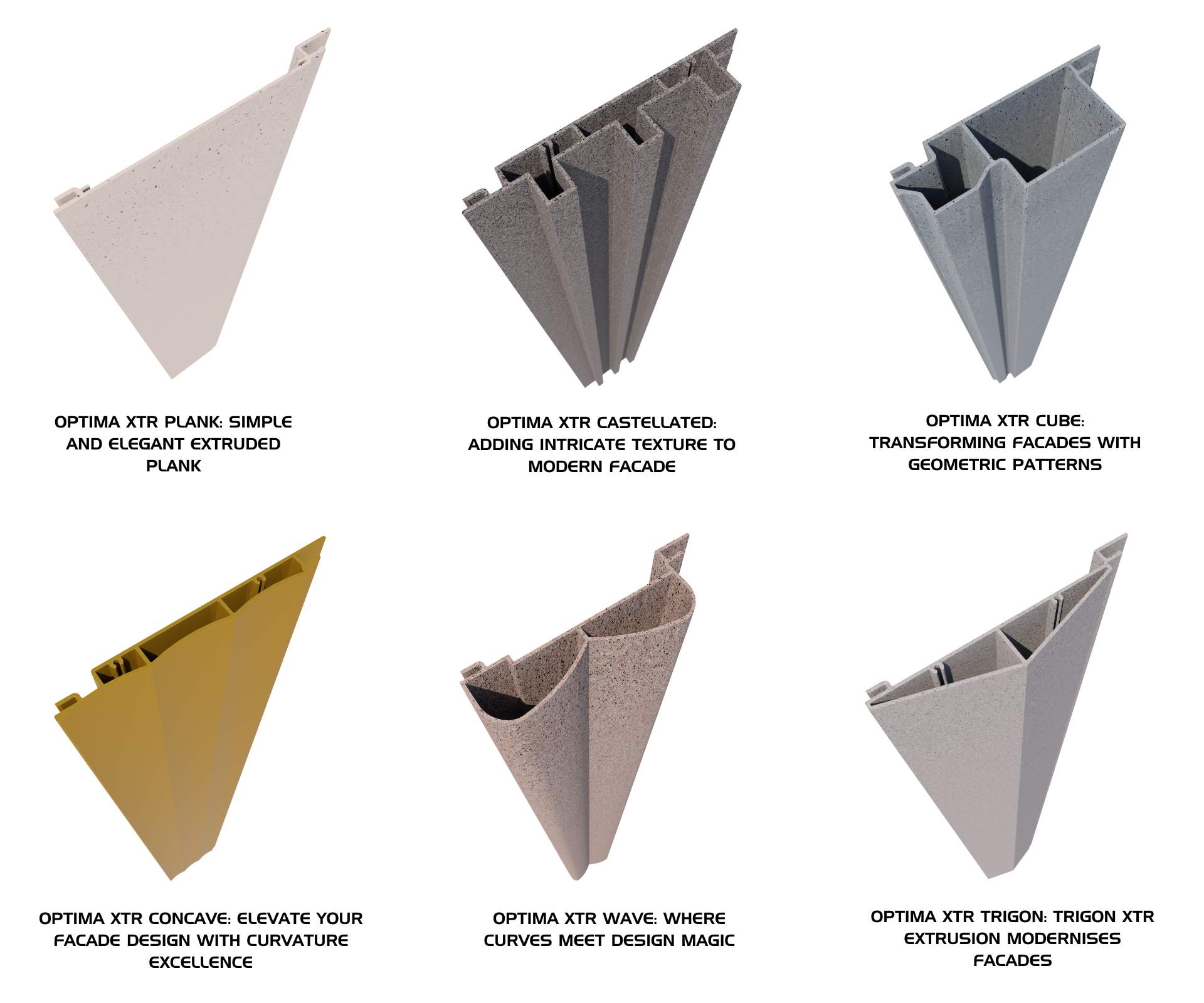

Originally designed as an alternative to terracotta cladding, the Optima XTR Contour range offers a diverse selection of profiles to suite various design preferences, and is available in six dynamic profile choices – cube, wave, plank, concave, castellated and trigon.

Introducing the XTR EXTRUDED Contour Profiles:

The ‘plank’ profile provides a sleek, even finish, while the ‘cube’ option offers four distinct profiles that can be employed to achieve a uniform square appearance or an intricate combination of all four profiles.

The ‘wave’ extrusion boasts six specially curved profiles that work harmoniously to produce a captivating wave-like effect.

In contrast, the ‘concave’ profile imparts a sense of dynamic movement and flow.

For those seeking dramatic visual contrasts, the ‘castellated’ profile generates prominent high points and elegant low points, resulting in an impressive visual effect.

Lastly, the newest addition to the XTR Contour family – XTR ‘trigon’ – broadens the range’s design potential by creating the visual illusion of diverse angles, further expanding the ranges design possibilities.

How is XTR EXTRUDED Contour Manufactured?

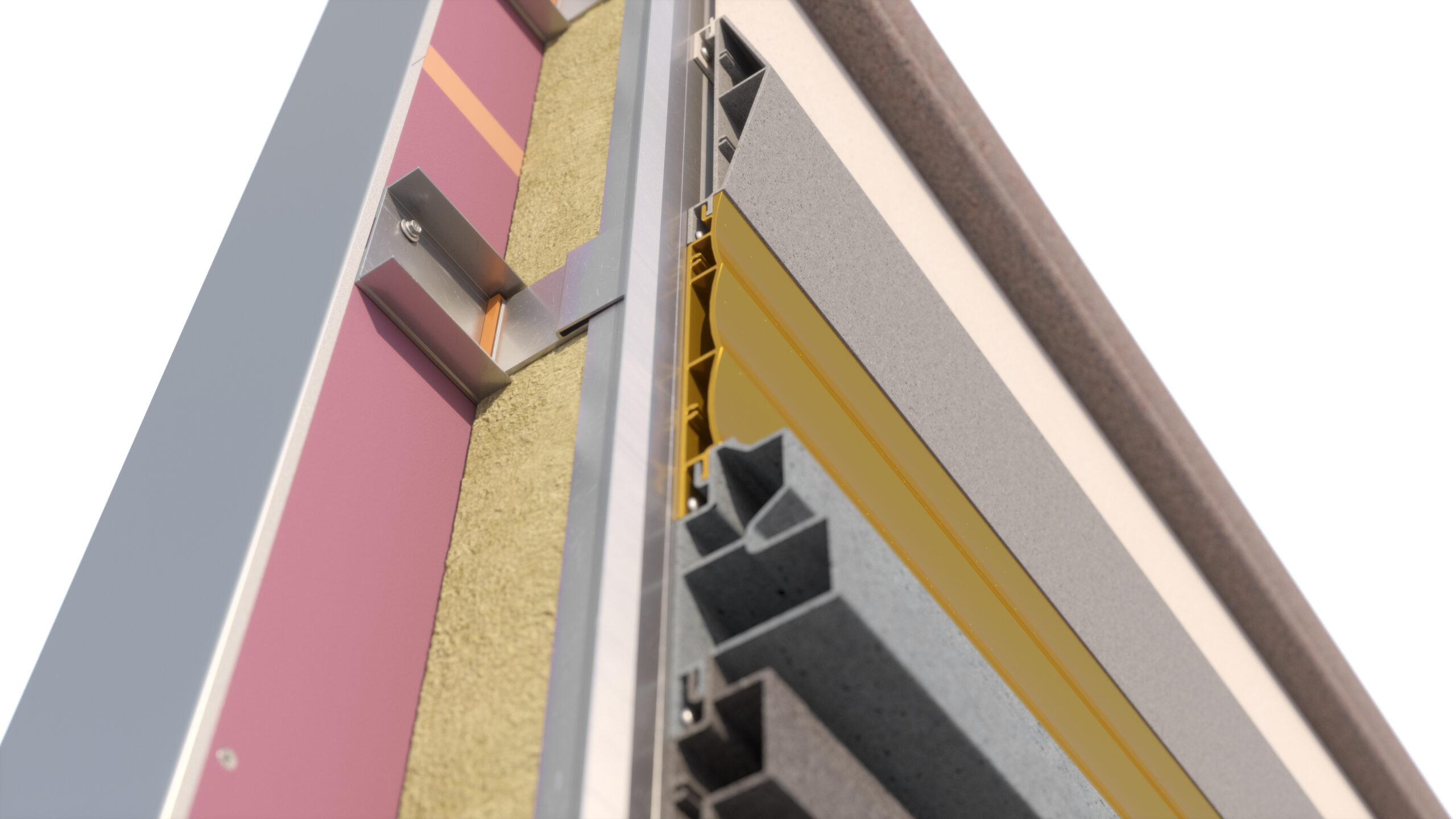

Named XTR to represent ‘extrusion’, the extrusions are formed when the aluminium alloy is pushed through a die into profiles – or complex shapes – according to the architect’s vision. The extrusions are produced from 6063-T6 grade aluminium. They are then secretly fixed onto an extruded aluminium support framework horizontally, vertically or diagonally.

The system is based on interlocking profiles, with a secret fix, and available in a range of finishes and can be fully A1 or A2 rated.

All six dies – cube, wave, plank, concave, castellated and trigon – are available now for full specification.

The profiles can be finished in a wide range of anodised colours including natural, bronze, and coloured and in different appearances including brushed and polished. They are also available in a wide range of PPC Ral colours including stone effect which provides a fantastic alternative to concrete, Portland stone, limestone and brick.

What are the Benefits of the XTR Extrusion Range?

XTR Extrusion rainscreen cladding is:

- Stunning, eye-catching extrusions that can be customised and designed to an architect’s very specific and unique vision.

- Can be fitted horizontally, vertically or diagonally.

- All profile interlock, meaning a ‘wave’ design can be interrupted by a ‘concave’ design for intrigue and contrast.

- Extremely hard wearing (with superior deflection and impact resistance) because it is made from extruded aluminium 6063-T6 and finished in a PPC or anodised coating. This makes it the perfect option for high traffic environments, such as school yards, residential builds and congested areas.

- Much lighter than the traditional terracotta material, which is naturally heavy and challenging to work with because of its ‘brick-like’ qualities.

- Highly cost effective because it is an engineered product as opposed to a naturally sourced resource. Other cost benefits are derived from the ease in which we can adapt and mould the panels, and the time savings created in the manufacturing process.

- Extremely versatile – all commercial finishes can be incorporated on one elevation to create an almost limitless effect of colours and shapes.

- Incredibly easy to install, leveraging an interlocking male-female joint with a secret fix. Extrusions are fixed using wafer head, self-tapping stainless steel screws.

- Project specific CWCT tests available. We offer project specific testing and certification to ensure compliance with industry standards.

What Designs are Achievable with the Extruded Aluminium Optima XTR Contour Range?

The Optima XTR Contour range can be produced in an incredible range of shapes and sizes.

As standard, Sotech is able to provide six dies which cover the needs of most projects. However, the expert technical team is able to produce an incredible range of dies for highly unique project builds. Should you have a specific design concept in mind, we can customise an extrusion solution to precisely align with your unique design needs.

“As with every project we take on”, said Jamie Smith, Commercial Manager, “we always seek to bring the architects vision to life. If we have a template for it on the factory floor, brilliant! But if something needs to be designed, engineered or manufactured to suit a bespoke brief or challenging project, we will rise to the challenge!”

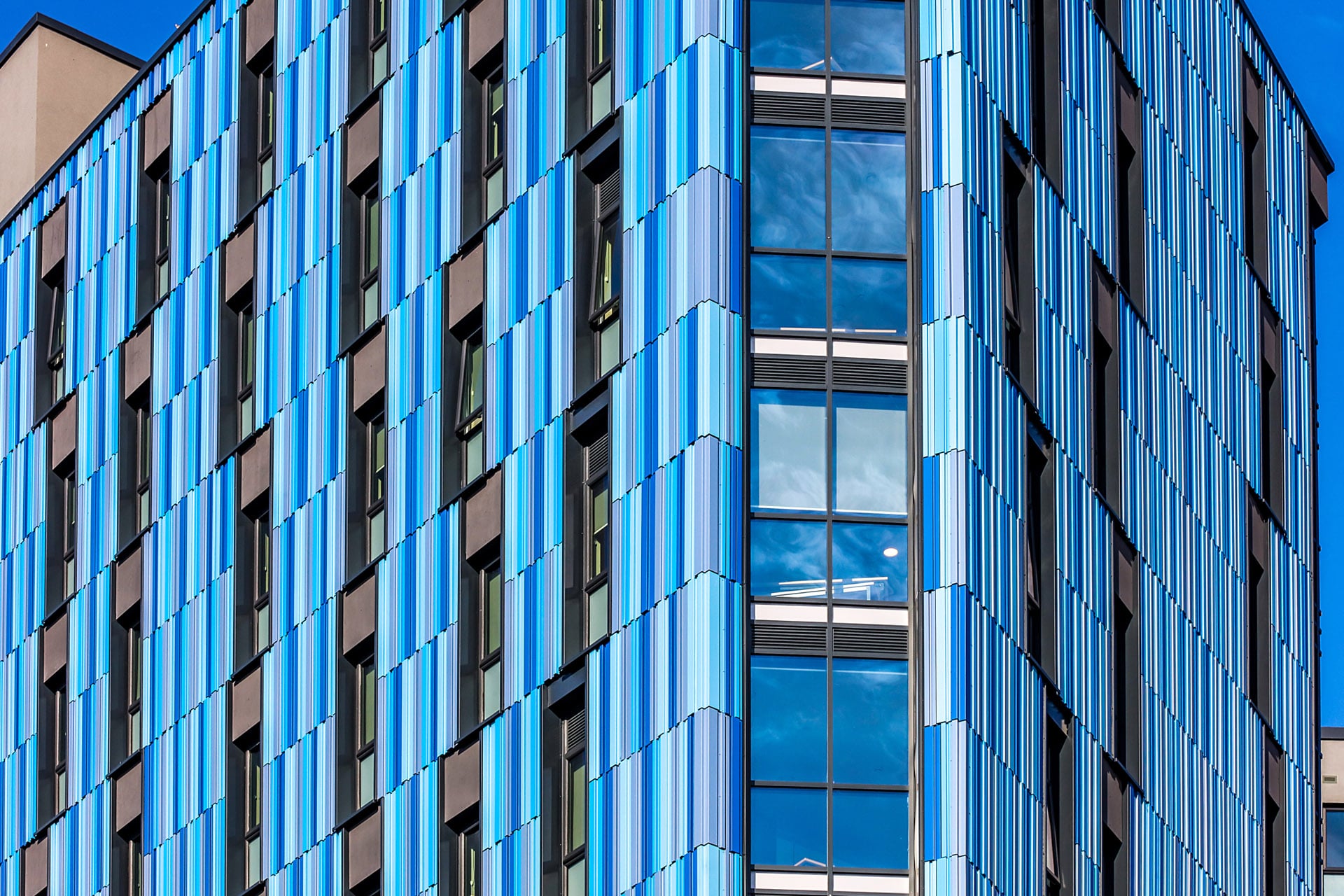

For example, the plank and wave profile was used in the creation of the XTR contour panels in Ferry Lane in London. This is an exciting project that regenerated the former Ferry Lane Industrial Site along Walthamstow’s High Maynard Reservoir, into an environmentally-sensitive, high-quality and sustainable Build to Rent development.

As you can see in the photos, the wave extrusion was finished in a bespoke powder ‘Ferry Red’ that creates a stunning effect throughout the day. The plank and the rainscreen panels were finished in various RAL colours from silver to cream to anthracite.

Likewise, Bath Court required a cube profile and the team were able to create a whole new set of dies for this project, which completed in 2020. The purpose-built student accommodation in Central Birmingham acts as a gateway into the city centre. Bath Court was nominated in the Best New Build category in the 2021 Façade Awards.

With Imperial 2 in Bromley By Bow (London) 300 m2 of Optima XTR Contour Concave profile in 6063 T6 Aluminium Extrusion was used alongside 3000 m2 of Optima TFC+ in Aluminium 3103 to create an industrial finish. XTR Contour was chosen for the project as it allowed the design team to mimic the pre-cast concrete fluted panels in a consistent manner.

The Optima XTR rainscreen cladding system is an economical, robust and lightweight extrusion , with a rapid turn-around speed.

All six standard dies are available to view and sample at online or in person at Sotech’s London and North East showrooms.

Click the links below to learn more.

Useful links:

Speak to an expert member of the Sotech team

![[NEW VIDEO] Thank you to our customers, suppliers and employees…](https://sotech-optima.co.uk/wp-content/uploads/2019/12/Queen-Margaret-600x600.jpg)

No downloads in list yet.

No downloads in list yet.