Classification Report (BR135 reports)

BR135 is the performance criteria for assessing cladding systems tested using BS8414. This classification applies solely to the specific external faCade system which has been tested.

BS8414 is a large-scale system test that mimics a fire braking out of a window and exposing a cladding system to a severe fire.

In addition to BS8414, the British Standards Institute has drafted a new standard for extended application – BS9414. Extended application enables a prediction to be made on the expected fire performance of a system, such predictions are based upon the need to abide strictly with the principle that the fire performance of the modified system would be equal or better if it were subjected to BS8414 test.

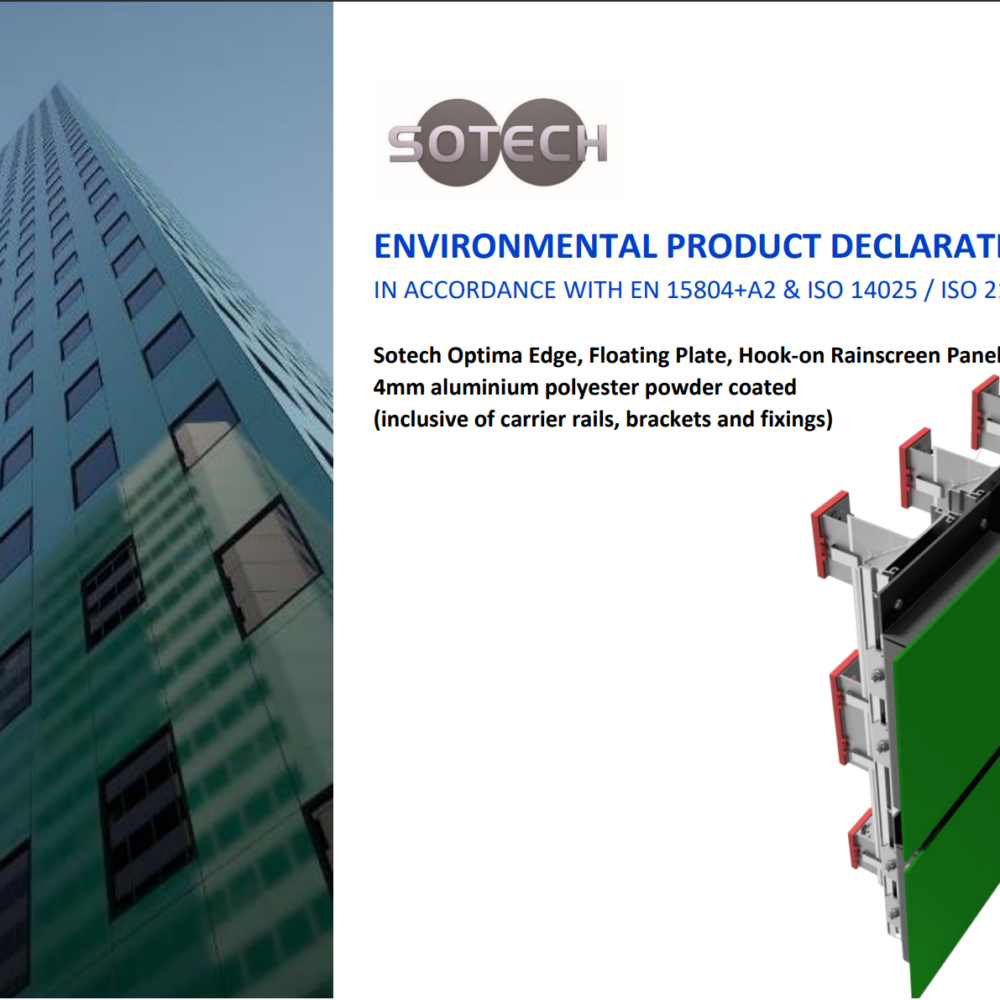

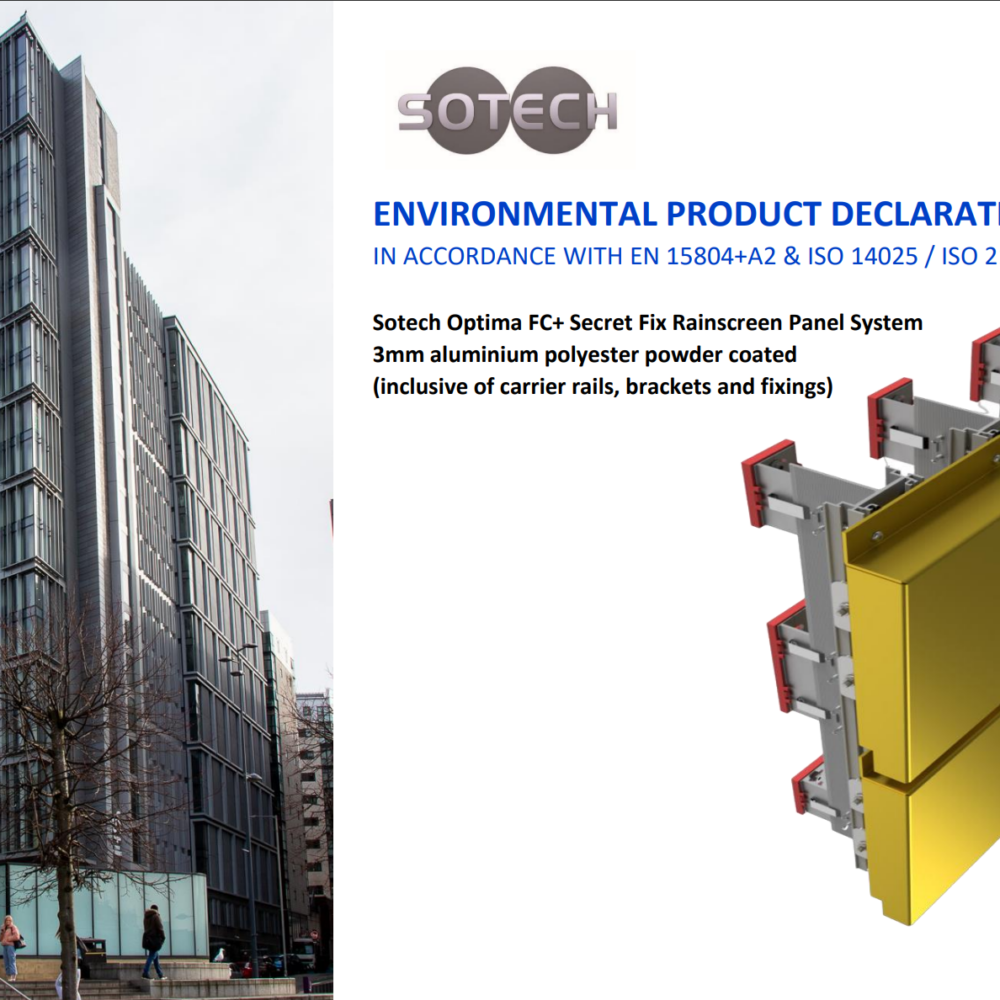

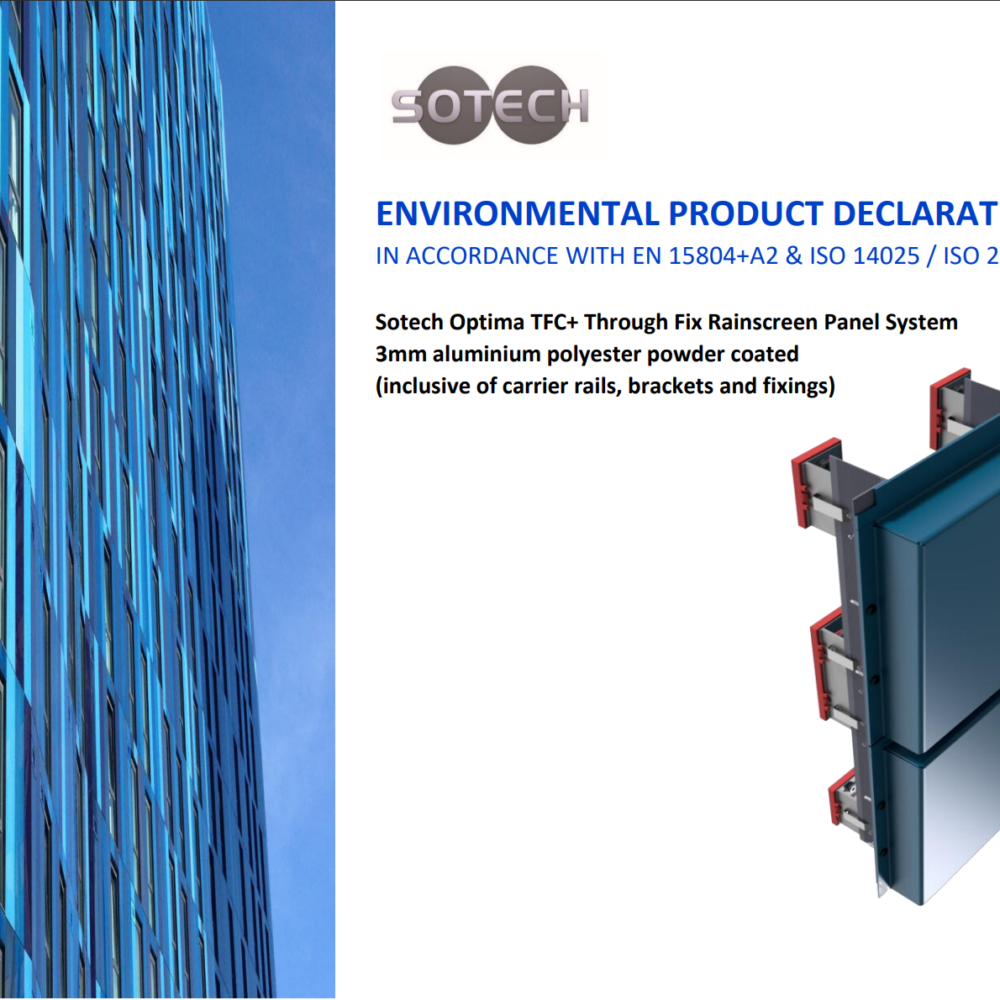

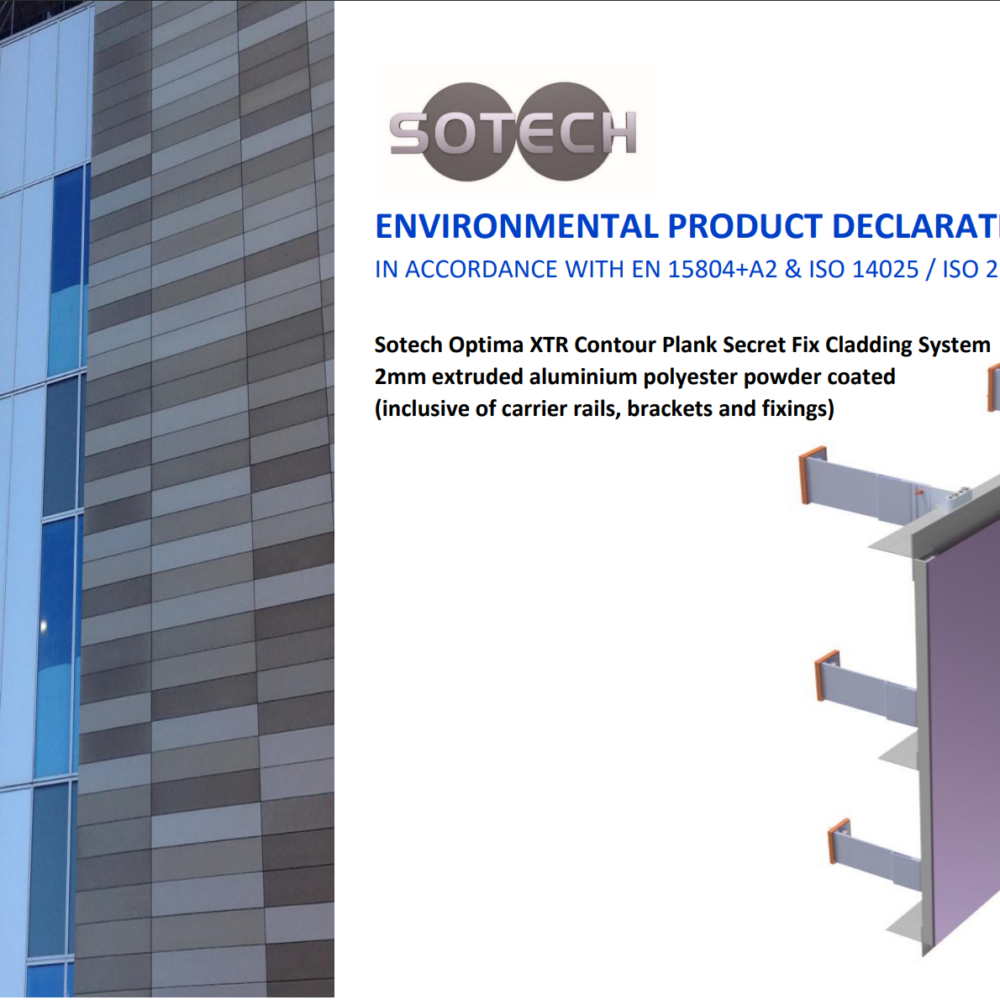

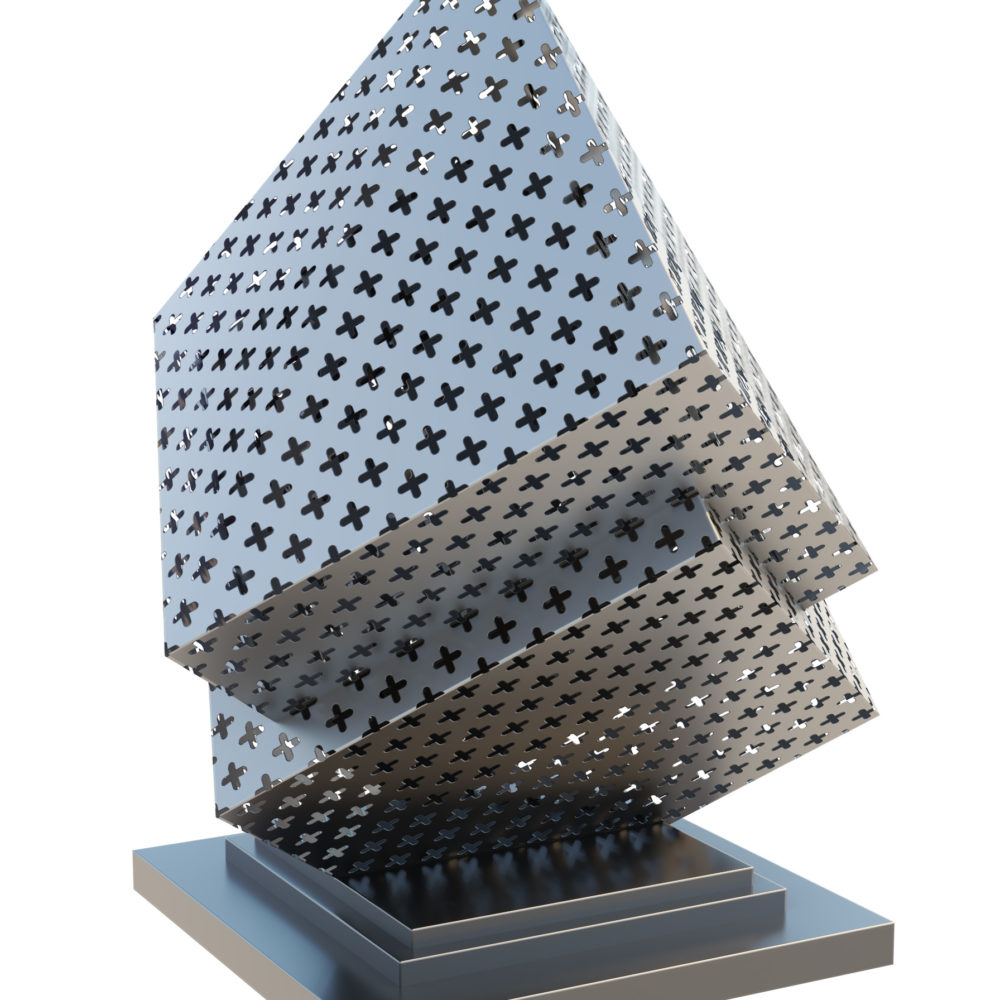

Tested to BS8414 standards and gained A2 cladding BR135 classification. Sotech can offer A1 cladding build up under BS9414 standard.

EN13501 provides the reaction to fire classification procedure for all construction products, including products incorporated within building elements (These reports are available upon request).

Performance Testing

CWCT (Centre for Widow and Cladding Technology) has developed a performance standard for the weather tightness of building envelopes, covering airtightness, impact resistance, water tightness and wind resistance.

-

ACM A2 – Alpolic A2

£0.00 -

ACM A2 – Alucobond

£0.00 -

ACM A2 – ALUCOIL LARSON

£0.00 -

ALPOLIC A1

£0.00 -

Copper – Aurubis Nordic

£0.00 -

Copper – TECU

£0.00 -

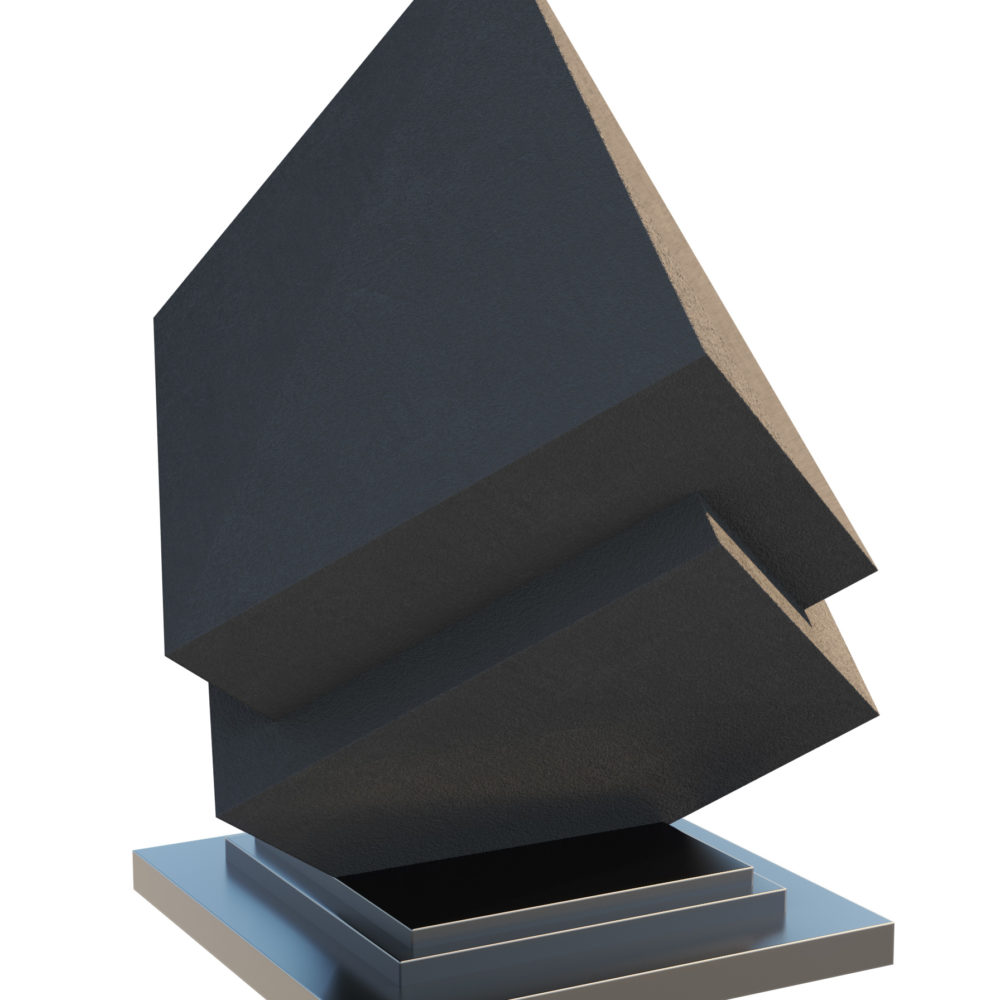

Corten Steel

£0.00 -

PPC Aluminium – Axalta

£0.00 -

PPC Aluminium – Interpon

£0.00 -

Stainless Steel – RIMEX

£0.00 -

Zinc – VMZINC

£0.00

No downloads in list yet.

No downloads in list yet.