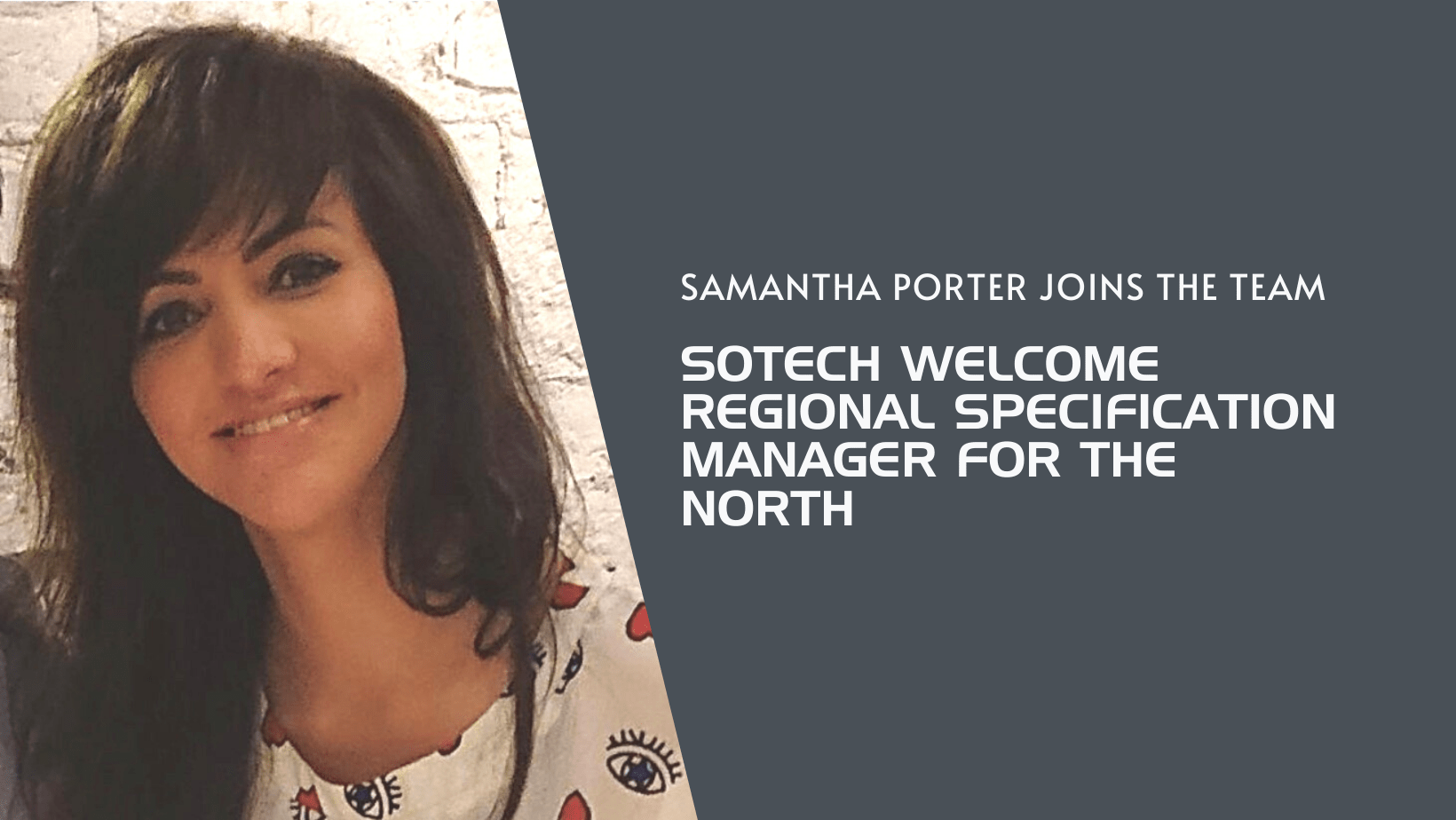

The Sotech team is delighted to welcome Samantha Porter who has joined the business as Regional Specification Manager for the North.

Working alongside installers and architects, Sam will provide technical support, complete NBS specifications and present RIBA approved CPDs for our customers and architects.

Having worked in the building envelope space for over 9 years, Sam brings a wealth of technical and design experience across a huge range of materials and finishes in the façade industry.

Today, we sat down with Sam to find out more about her background and what she will bring to the rainscreen cladding industry.

Tell us about your background:

I joined the construction industry nine years ago as Business Development Manager for mineral wool composite facade, fire wall and roofing systems, covering the M62 corridor down to Essex, before moving on to become the Specification Consult Manager with an aluminium window / unitised and curtain wall supplier. The last four years of my career have been spent with a supplier of panelised composite facade and built up/panel backed rainscreen systems.

During this time, I have worked with clients, specifiers, contractors and installers and gained a solid technical grounding on the detailing and performance requirements of key building elements. Specifically, I have focused on the ways in which various materials impact acoustics/thermals, fire and span, and how system limitations and budget considerations can be managed to complete visually stunning projects on time and in budget.

One thing I enjoy bringing to the conversations is my passion for simple solutions that outwardly look highly complex. Rainscreen systems – with their variety of coatings, materials, shapes and methods of construction – can create extremely impactful architecture, on budget and in line with the stringent regulations we see today.

What do you think is important in the construction sector this year?

Fire performance, safety and sustainability have been extremely prominent topics for many years but increasingly so over the last four. We’ve seen the catastrophic effects of a breakdown within construction and its various stages as addressed in the Hackitt report. The ‘Golden Thread’ has become a primary topic in the last year where guidance will be developed for safety to be considered at every stage of the building’s life cycle.

As the NBS describe it there will be primary legislation that will put a legal duty on duty holders and accountable persons regarding this information development. Secondary legislation will define the principles, information, data and documents required – and the processes, including information gateways. Guidance will be developed to lay out best practice and practical ways of meeting this legislation.

We have also seen first-hand the substantial government and homeowner costs that have come from the requirement to reclad buildings that are not safe or suitable. Traceability, consistent and accurate information from all parties, as well as clear accountability throughout the stages will make significant improvements in constructing sustainable buildings.

What can you bring to architects and installers in your new role?

My role is to give designers their optimal choice of facade to meet the design, as well as provide an alternative solution that provides a similar aesthetic, under a tighter budget. So much of my experience in project management and specification delivery across mineral wool composite facade, fire wall and roofing systems, along with my work in panelised composite facade and built up/panel backed rainscreen systems can contribute to this.

As with any project, light compromises to the aesthetic might be required to contain costs as a project evolves, but rainscreen systems provide such an incredible range of options, that the aesthetic can often be reached, whilst performance requirements and regulations are met. I look forward to have these conversations and exploring the vast array of options available with our customers.

What is your favourite building in the UK and globally?

Admittedly I do not have an official favourite UK project but there are a few that stick out for me as being unique.

Firstly, the Millennium Centre in Wales for its industrial but effective use of face fixed steel in a dome with perforated signage that lights up at night.

I love First Street’s ‘HOME’ too – the cinema in Manchester – for the dual colour precoat that changes from purple to blue as you alter your direction perspective.

And corten aside – I’m more of a fan of the PPC alternative – Broadcast Place in Leeds must go on the list as it looks like stacked boxes. It’s a simple design with an impressive overall impact on the skyline.

Out of the UK without a doubt it is Hotel Marques De Riscal by Frank Gehry. It’s a winery hotel as the name suggests in Wine City, Rioja. Its roof is made up of a continual ‘ribbon’ effect, and the aluminium in its iridescent purples which gradually change to silver gives a look of flowing wine.

What attracted you to Sotech?

What can I say? Sotech’s reputation for excellence proceeds itself. Sotech has put a huge focus on fire safety offering an extensive range of A1 and A2 system materials and has also invested a significant amount of money in testing to CWCT, BS8414-2 and gaining relevant ISO accreditation for quality, environment and health and safety. Specifiers, contractors and installers can feel confident when putting forward Sotech systems.

I also respect the technical and manufacturing capability of the team with its ability to think outside the box and develop bespoke but simple solutions, where the installation and functionality can be showcased in 3D models. I remember asking architects why they always chose a certain glazing system to specify and was told ‘they just make it so clear and easy to do so’ and I think that hits the nail on the head with the way in which Sotech operates.

No downloads in list yet.

No downloads in list yet.