Sotech Teams up with Fronius UK to Enhance Core Welding Processes

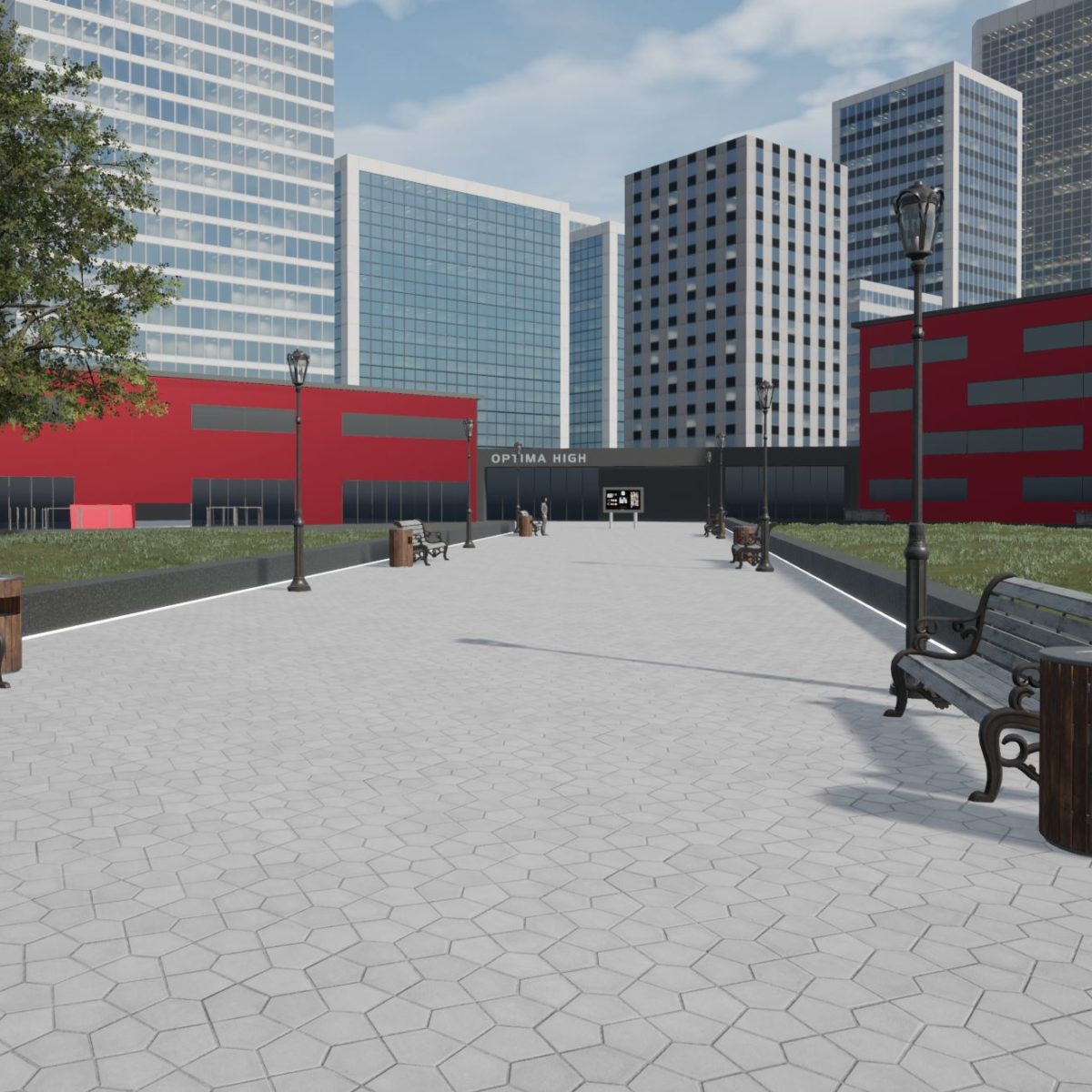

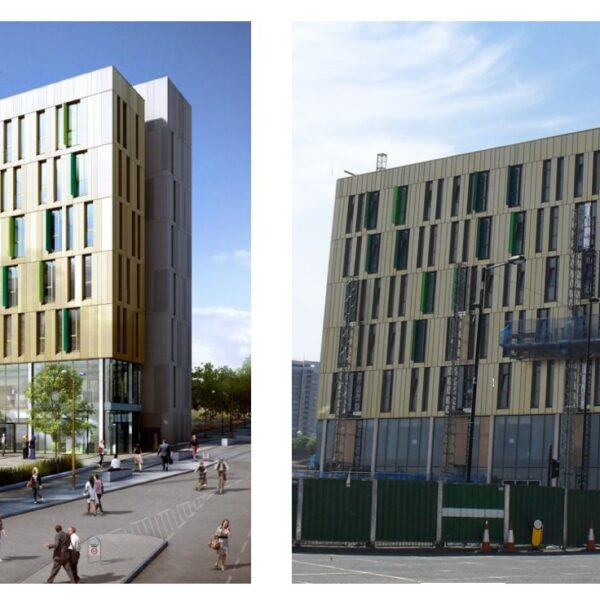

Sotech, the renowned manufacturer of the Optima range of metal rainscreen façade solutions, has joined forces Fronius UK, a world-leader in welding technology, to upgrade the core welding technology in the business.

The cornerstone of this investment lies in the integration of Fronius’s signature welding processes, which employ pre-programmed welding sets to significantly boost the speed, efficiency, and productivity of manual welding work.

The new Pulse function of the TransSteel 3000 Ie 300 amp machine enables faster welding speeds on thicker materials and the pulsed arc also reduces the amount of rework, as less welding spatter is generated. Meanwhile, the CycleTIGfunction of the iWave solution allows the user to control the heat input of the arc to the maximum extent. This makes it easy to weld even the thinnest of materials. This transformative shift not only streamlines production but also minimises material wastage, as the new welding tools exhibit unparalleled precision.

Dave Swithenbank, Drawing Office Manager who has led the project at Sotech, shared his thoughts on the partnership: “Sotech’s welding team is highly trained and highly experienced. This collaboration with Fronius is designed to enhance the team’s skillset with more advanced technology and more sustainable practices. The new machines will enable the teams to be even more precise, whilst using less energy and even less material wastage in their welding processes.”

To fully harness the potential of these innovative new welding tools, Fronius has invited the Sotech teams to their training facility in Milton Keynes to demonstrate and test the full range and power of the pre-set welding programmes.

Barry Craggs, the Sales Engineer for North East and Scotland, expressed his enthusiasm about the partnership, saying, “Our state of the art welding tools are not designed to replace a welder’s skill but to enhance it, using sets and programming to help the teams complete the jobs at hand with even more precision and speed. The teams will have to see it to believe it, and that’s why we have invited them to share their most difficult welding challenge with us so we can demonstrate the power of the Fronius tools in our fully equipped training centres in Milton Keynes.”

Sotech’s unwavering commitment to staying at the forefront of rainscreen design is underscored by this continuous investment in new skills, cutting-edge technology, and innovative processes for the teams. This new partnership with Fronius reaffirms the company’s dedication to pushing the boundaries of what is achievable in the industry, as well as a drive to find ways to increase and improve sustainability at every stage of the design process.

In this way, Sotech and Fronius share more than just a vision for technological advancement. Both companies are family-owned, with a sincere focus on multi-generational sustainability.

Barry noted: “The Fronius welding tools are future-proofed. They are durable and robust, and will stand the test of time, but they are also repair-friendly and upgradable. Major components can be serviced and replaced individually to extend lifetime usage and reduce the impact on the environment. Our tools have also been rigorously tested, including impact tests, metal dust tests, drop tests and cold behaviour tests”.

Dave added: “One thing that stands out is the future readiness of the Fronius tools. The Fronius tools are industry 4.0 ready meaning they are connected, with contactless data transmission and authentication. This fits in with Sotech’s drive towards automated processes and data transparency across the manufacturing floor.”

Sustainability is a top priority for Fronius UK, aligning perfectly with Sotech’s mission to adopt more efficient practices and promote responsible use of the Earth’s natural resources.

In summary, Sotech’s collaboration with Fronius UK marks a pivotal moment in the evolution of welding processes within the architectural and construction industry. By incorporating Fronius’s state-of-the-art welding technology, Sotech is poised to unlock new levels of speed, precision, and sustainability, reinforcing its status as an industry leader in rainscreen design.

No downloads in list yet.

No downloads in list yet.