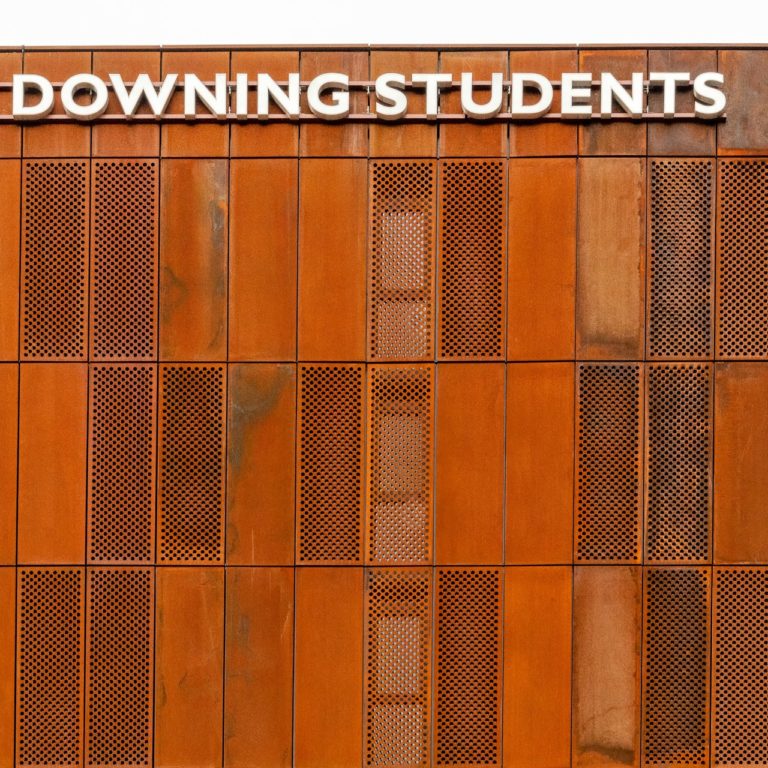

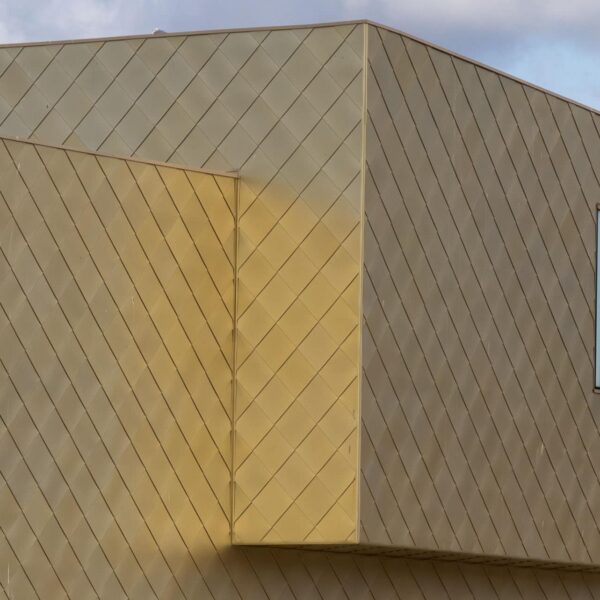

6500sqm of Optima FC in Cor-Ten weathered steel rainscreen panels have been used in the state-of-the-art student accommodation on River Street.

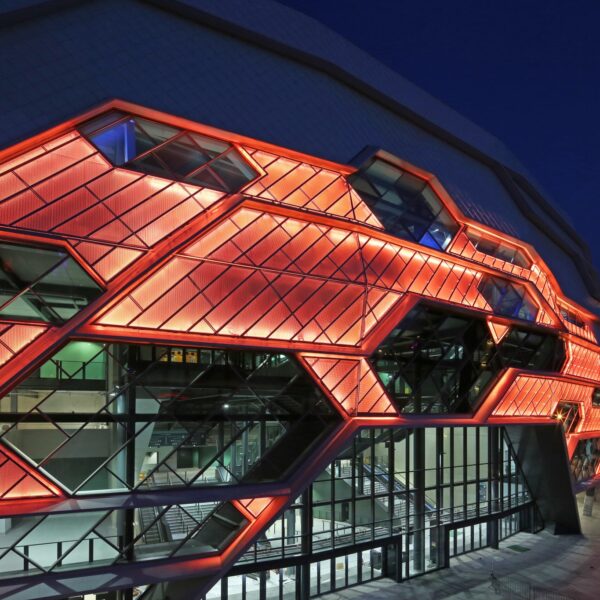

As described by Architect Simpson Haugh, the student accommodation comprises three distinct volumes: a volume stepping from ten storeys fronting Garwood Street, down to five storeys facing River Street, and a 32-storey tower.

Cor-Ten, a steel alloy which forms a rust-like appearance over 18 – 36 months, was selected for the project due to its striking appearance and in tribute to the copper shades surrounding River Street’s built environment. Cor-Ten is immediately recognisable with its bright red and orange tones.

The strong textures of the Cor-Ten provide a fantastic contrast to the dark-blue glass cladding covering the inner elevations.

Originally designed for use in coal carriages in 1930s American, the name Cor-Ten was patented in 1933 by U.S Steel, deriving its name from ‘Corrosion Resistance’ and ‘Tensile Strength’.

Whilst it might look like the metal is rusting, the outer layer of the metal is actually undergoing a planned corrosion process under the influence of outdoor weather elements, which protects the metal from further corrosion over time.

Referencing the corrosion process, Sotech Specification Manager Charlie Mclaughlin said: “Cor-Ten panels developed a patina in-situ on the buildings as a response to the elements. The local climate should be ideal. It was great to do another job with Simpson Haugh, especially on a site just a stone throw from their office.”

Sotech’s Optima FC secret fix hook-on rainscreen system was installed to carry the panels, this fully tested system had the added precautions of stainless steel hooks and polyester powder coated rails to eliminate any bimetallic reaction between the Corten panels and aluminium support system.

As you can see from the project photos, the Cor-Ten panels were perforated with hole cluster patterns positioned to coordinate with extractor vent outlets in the backing wall. This is achieved through a laser cutting process.

As experts in the industry with over 30 years’ experience, Sotech wasn’t just involved at the manufacturing stage, but were engaged from design stage, offering details, advice and budget costs during the project.

With 792 bedrooms and state of the art social space, the building fills a spot in Manchester’s landscape that had been empty for years.

Project name: River Street Tower, Location: Manchester, Sector: Student Accommodation, Installer: Alumet, Main Contractor: Downing Construction ,Architect: Simpson Haugh

Testimonials

Laurence McBeth, Sales & Commercial Director of Alumet Systems

“River Street Tower is the first project we have completed with Sotech and we are thrilled with the end result. Sotech provided Alumet with technical support, advice on product offering and design solution and worked closely with the site team to deliver the panels in levels to a very well managed schedule. From start to finish the service received was first class and we are looking forward to working together again in the near future.”

Associate of Simpson Haugh Architects, Jonathan Mallinson

“Our relationship with Sotech goes back a number of years from first specifying their rainscreen systems on The View, an earlier project for our client Downing in the North East.

Since this time we have specified their products on a number of schemes nationally. From the early stages of projects Sotech have been happy to provide samples for review, planning and client sign off as well as providing technical assistance as projects progress through to site.

For the River Street project we specified Cor-Ten, as both solid and perforated panels.

As a material Cor-Ten can present challenges in terms of detailing however these challenges were successfully worked through collaboratively with Sotech and the façade subcontractor Alumet to provide a level of articulation and finish we are very happy with.”

Tony Norton, Operations Manager for Sotech

“River Street stands out over Manchester landscape and includes 31 floors of Cor-Ten panels, it is the largest Cor-Ten project we have completed. It was a pleasure working with Alumet especially the site team to achieve the final result”.

No downloads in list yet.

No downloads in list yet.