A staple of the London city skyline, Guy’s Hospital tower has had a recent growth spurt, with a complete refurbishment of both height and performance.

Having overtaken Hong Kong’s Sanatorium Tower by a mere 15mm, it is now the tallest hospital tower in the world at 148.65 metres. But, it’s not all about the size; the building’s heat gain and loss has been reduced by almost 20% thanks to innovative new aluminium overcladding.

Consisting of two distinct ‘user’ and ‘comms’ structures connected by a bridge, it was the deterioration and spalling of the towers’ concrete exterior which initiated the refurbishment. According to Neil Allfrey, associate of the architectural practice behind the project Penoyre and Prasad, one of the building’s main concerns was that “the user tower’s plastic coated double-glazed steel windows suffered extensively from condensation, and there was no insulation in the brick walls that formed the spandrel panels below them.” Rather than re-cladding the entire construction, there was a focused approach on the most problematic areas, including the windows and spandrels of the user tower, the concrete on the comms tower and the bridge joining the two.

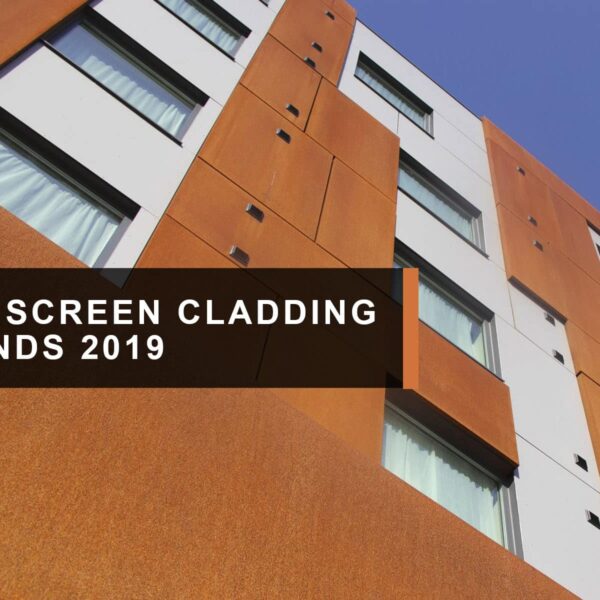

Once the eroded concrete façade was addressed and repaired, horizontal cladding rails were attached with L-shaped brackets, ready for new, environmentally friendly anodised aluminium panels to hang from; a material chosen in an attempt to reduce additional weight on the building rather than for its aesthetic benefits. However, after further analysis showed that to be unable to deal with the extreme wind speeds often experienced at the top of the tower, an even lighter (but more suitable) aluminium cladding was chosen.

To make a visual impact, folded and flat anodised panels in a bluish grey and umber were used in both solid and perforated textures to create a reflective statement to be seen all across the capital.

To tackle heat problems on the connecting bridge, full 3.8 metre height double glazed panels were added and made fit to purpose according to each side of the bridge, with low ‘e’ glass on the north side to prevent heat loss, and low ‘g’ glass on the south to prevent heat gain; a masterclass in innovative solutions to an individual building’s issues, and one that can surely be developed further in the future. There is still a problem with cold on the bridge, where the balcony meets the floor, but the overcladding has been used to effectively minimise this as much as possible.

A potential problem that did require consideration was if the new cladding and façade systems did their job a little too well; what if they performed so effectively that they caused excessive internal overheating? But, the results put those fears to rest, with heat gains and losses expected to drop by 18.5%, and the building’s total energy consumption by 7.6%. The carbon emissions are also predicted to drop by 9.4%, with a carbon payback from the cladding materials to become evident in around 12 years.

It seems that using our imagination with a new breed of cladding and insulation to reflect light instead of containing it could be a vision into the potential environmental and financial benefits for architecture across our cities.

(Information taken from this article)

(Image from wikimedia.com)

Read more:

No downloads in list yet.

No downloads in list yet.