Rainscreen fins, perforations, balconies and etching:

When design flare meets performance rigour in rainscreen cladding

When it comes to selecting the perfect rainscreen cladding system for a project, such as a striking new residential complex in a busy city centre, or a large scale shopping centre set across a large site, a key balance must be met between performance and safety, and design and budget.

Sotech has long been known for its focus on performance and safety, providing robust, accredited rainscreen cladding systems for a range of budgets, with all systems carrying full CWCT certification and the Optima FC+, TFC+ and Edge having met the fire requirements of BR 135 when tested to BS 8414 in specific system configurations.

In this article, we’d like to put the focus on clever and original design adaptations in rainscreen cladding facades that can be used to create a striking finish that sets the building apart locally and nationally.

Optima Options

RAINSCREEN Feature Fins:

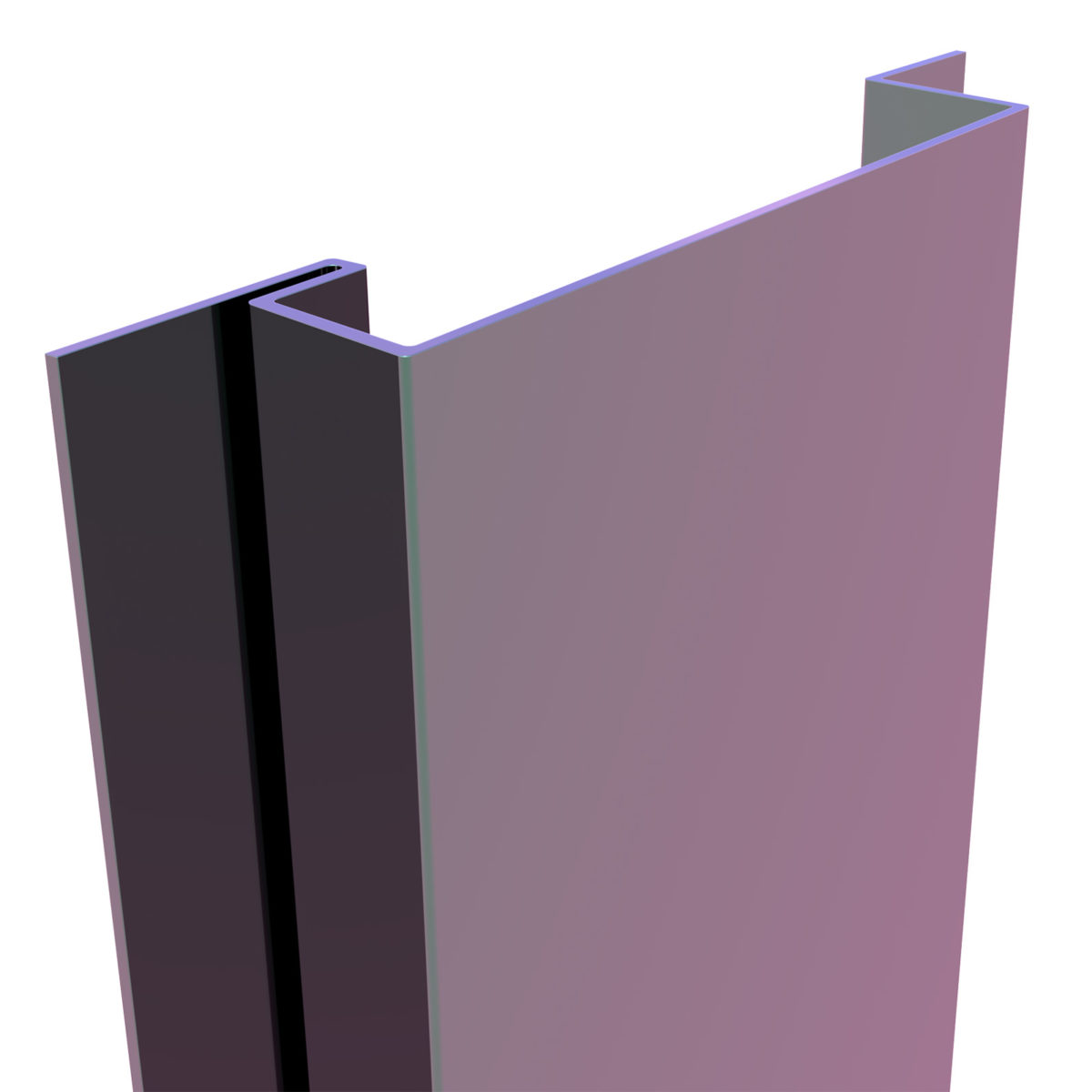

Architectural fins added to an Optima Façade can create dramatic vertical or horizontal emphasis to a building, whilst retaining the main rainscreen system performance.

Large or small feature fins can transform the look of a façade making the joints prominent, creating shade effects and giving the panels a more recessed appearance.

Architectural fins use the same fire rated materials and systems employed in the core design.

As an example of architectural fins in use, Optima FC was chosen for The Core, Science Central project. The features of the building include horizontal and vertical fins projecting out from the panel joints.

The gold anodised fins create a picture frame effect around each individual panel.

The installation of fins can be incorporated on site or fitted to the panels in the factory.

In this example at Thorpe Park shopping centre in Leeds, the Optima TFC system has been finished in anodised gold with matching feature fins. The fins are positioned to create an almost random layout for the shopping centre.

Fins can vary in size, depending on the architect or designer’s vision. For example, the Glasgow Centre Premier Inn Super tower is 18 floors high and perfectly located for visitors to the City. Sotech carried out FEA analysis and provided hidden extruded support channels to support the huge fins on this project.

Some of the panels for the project are in circa 5.5m in length making it one of Sotech’s first solid aluminium projects with panels larger than 4.2m.

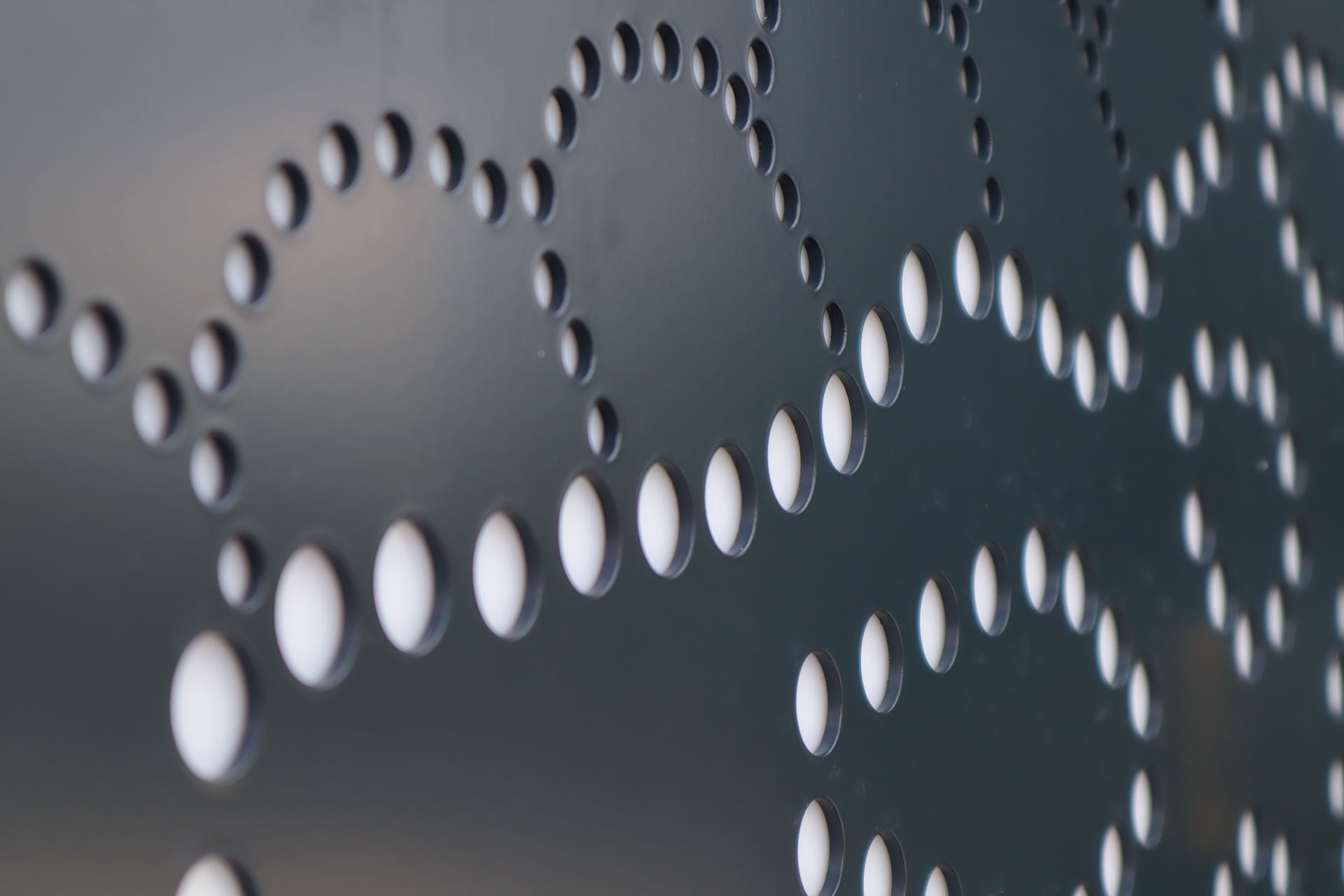

Perforations IN RAINSCREEN:

Perforations can be applied to a selection of rainscreen panels to create a unique pattern, to key features of a building to create contrast, or to specific sections to allow additional air flow (providing outlets for ducting and ventilation), or more light to pass through the panel (as for stairwells and balconies).

Therefore, perforations can be used for design purposes but they can also be functional, without the need to incorporate separate grill or louvre systems. For example, perforations can be used to allow light into a stairway without making foot traffic overly visible from the exterior. These perforations create a subtle difference with solid panels even though they are in exactly the same panel system and colour.

In this example on the Hilton hotel in High Wycombe, perforations have been limited to the entrance to create a beautiful and original feature design.

Sotech have an incredible range of perforation patterns available due to years of investment in the latest tooling.

Sitting in the Wembley Park regeneration area, Kelaty House is an example of how perforations are used to create stunning art across many individual panels to produce a much larger mural.

The perforated panels have been carefully orchestrated to form the highly original tree silhouettes, visible from a distance on the project, which is made up of five separate high-rise blocks.

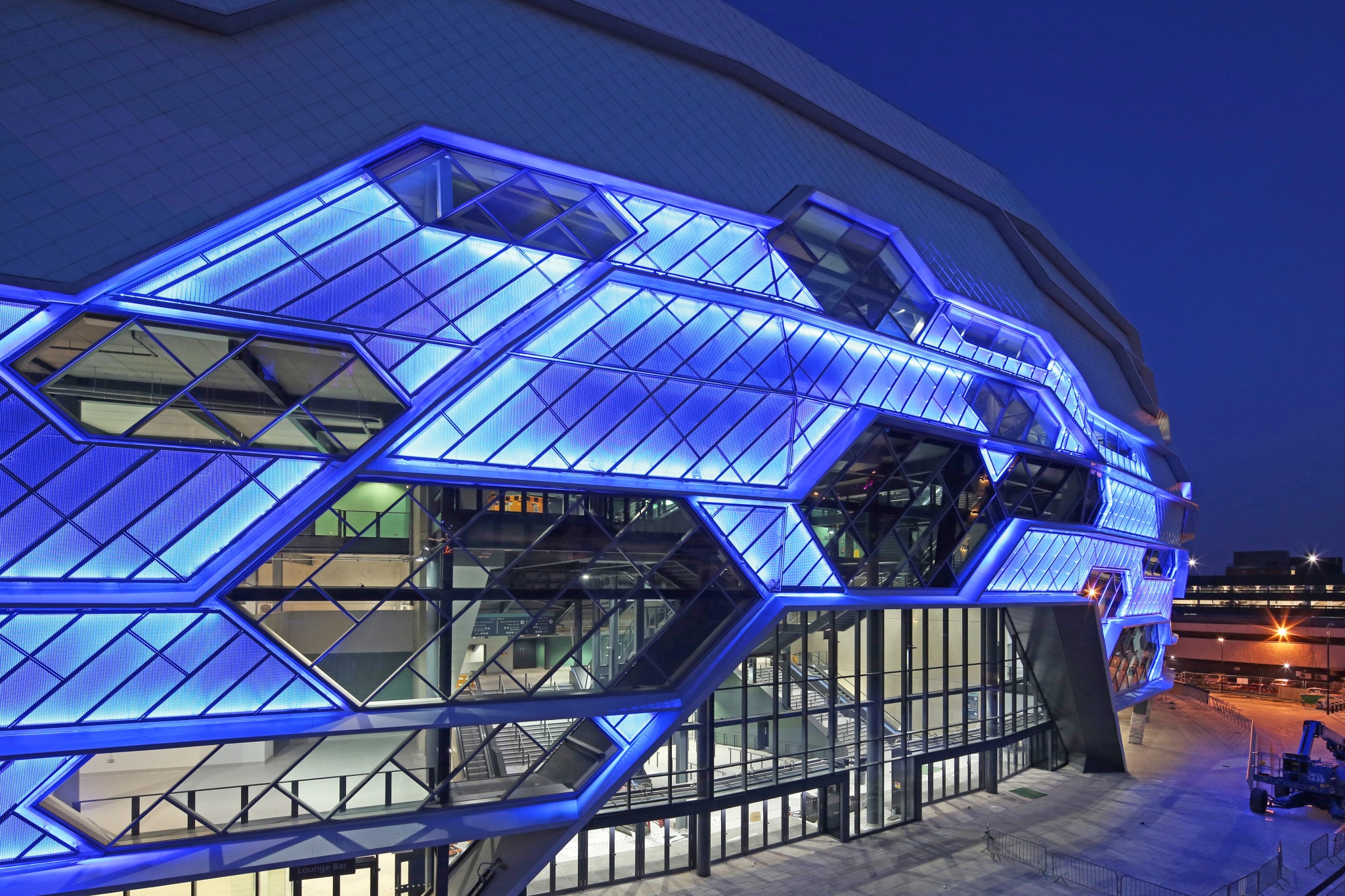

Perforated effects can be used with backing panels to create dual colour patterns within one panel face. To really highlight a perforated façade and bring it to life, LED lights can be used behind the panels producing a multicoloured display as shown in Frist Direct Arena, Leeds.

The panels subtly echo the cellular nature of the aluminium shingles during the day, but at night the seemingly randomly patterned perforations give way to an illuminated tracery, proving an almost psychedelic lighting experience featuring a palette of mesmerising, vivid colours which light up the Leeds skyline.

RAINCREEN Balconies:

Balcony cladding has increased in popularity in residential projects in recent years, with designers using popping colours and perforations to bring added personality, shape and intrigue to the final look of a completed building.

Sotech’s balcony cladding solutions use the same fire rated materials and systems as used in the core design.

Sotech offer the option of wrapping balconies in the same system types as used on the main rainscreen façade. This approach means that balconies become an integrated part of the façade, rather than add-on elements.

Chrisp Street in London links the balcony cladding and the main rainscreen façade was maintained by cladding the balcony edges in the same material as the floor edge features in the main façade.

Brushed & Patterned AnodisED RAINSCREEN

A highly unique and non-uniform effect can also be created through brushed and patterned anodising.

Brush lines can run horizontally and vertically, refracting light differently and therefore creating an entirely contrasting appearance when viewed from different angles or in varying lighting conditions.

You can see a perfect example of this in the bronze extrusion in Apex Phase 2 at Liverpool University.

Pictured: Apex Phase 2, Liverpool University (bronze extrusion only)

Another example can be found in Staffordshire University’s Science and Technology Centre.

Finished in anodised aluminium, the Sotech Optima FC Secret Fix rainscreen panels were designed to alter in appearance depending on the angle and time of day viewed.

This process leads to an eye-catching difference in the appearance normally associated with anodising, but does demand even greater care during manufacture to prevent any imperfections in the surface of the panels.

Pictured: Staffordshire University Science & Technology Centre

The technique can also be applied to different anodised finishes to dull down the extrusion and give a matt appearance.

In a different way, etching a pattern directly into the aluminium panel is another unique and striking way to add interest and uniqueness to a façade.

An example can be found in the award winning Leeds Beckett University where red on red etched anodised panels were created in contrasting tones to give the impression of muscle fibres under the microscope.

Pictured: Leeds Beckett University

Contact us:

Sotech has invested heavily over the decades to stay ahead of the curve when it comes to design, performance and safety. With investment in full scale fire testing, CWCT testing, the addition of the powerful Salvagnini machine, the creation of a dedicated technical and 3D modelling department and a strong northern and southern specification team, and the development of virtual reality worlds, Sotech can work with you to create a highly original, award winning design that sets the sector apart.

If you require advice with design detail, assistance with a specification or to discuss large scale testing in your next project, contact our technical department who have 40 years experience in the construction industry. The team is on hand to provide knowledge and support at every stage of your project.

All Sotech systems carry full CWCT certification and the Optima FC+, TFC+ and Edge have met the fire requirements of BR 135 when tested to BS 8414 in specific system configurations. Sotech is one of the few manufacturers that can provide true A1 Non-Combustible rainscreen systems. Sotech is also accredited to ISO9001:2015, ISO 14001:2015 and ISO 45001.

Overall 99.5% of all materials supplied by Sotech are fully recyclable – with no loss of quality. We ensure compliance with current legislation in relation to our products, processes and activities and we promote energy, waste and pollution prevention efforts, such as recycling arrangements wherever practicable. Sotech is committed to sustainability, with a goal to achieve The Net Zero Carbon Buildings Commitment 2030.

No downloads in list yet.

No downloads in list yet.