BIM

A method of 3D modelling that will bring a number of benefits to architects, installers and manufacturers alike.

Once you have added all the files you require to your download list you can gain access to them using the downloads button in the top right or bottom right of your screen. If you have any issues, comments or questions please get in touch and an expert will be in touch as soon as possible.

Learn More…

The Learning Zone plays host to innovative design workshops, CPD seminars and launch events where designers, contractors and material manufacturers can meet, evaluate and review projects and address technical issues at the very start of the design process.

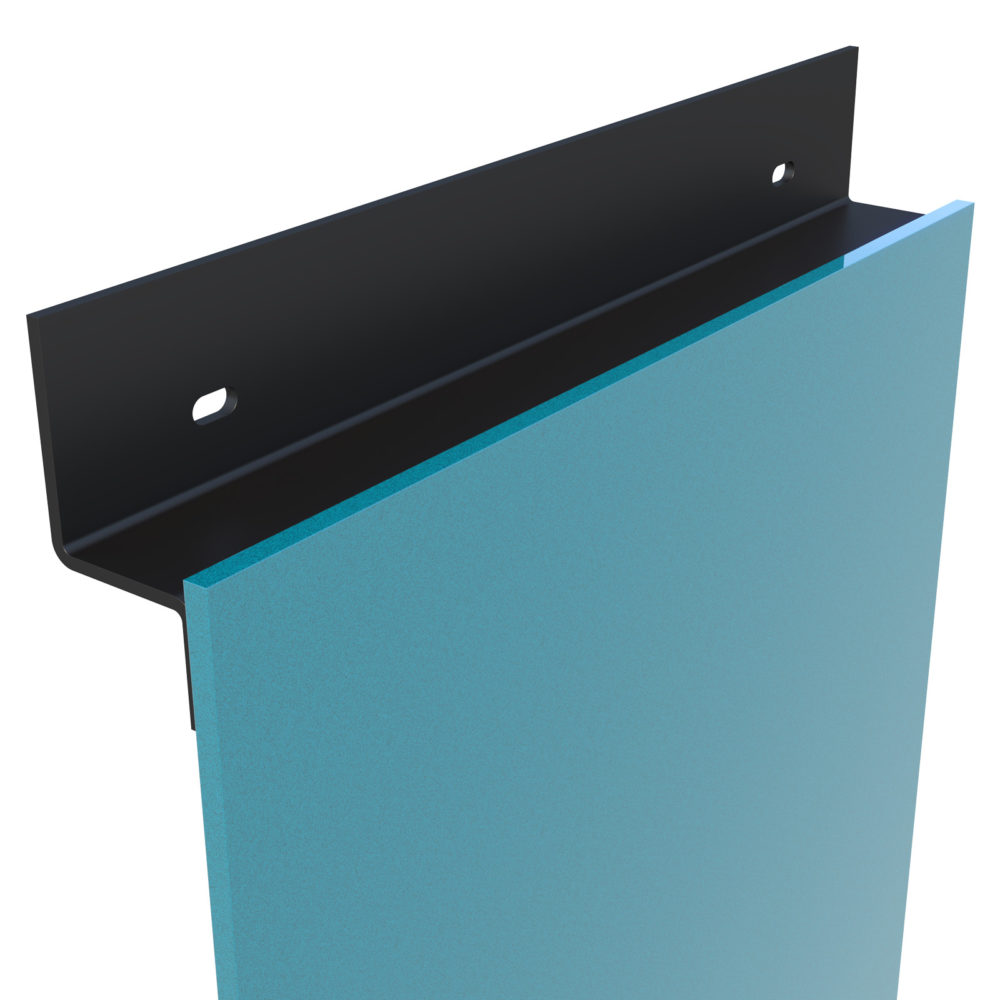

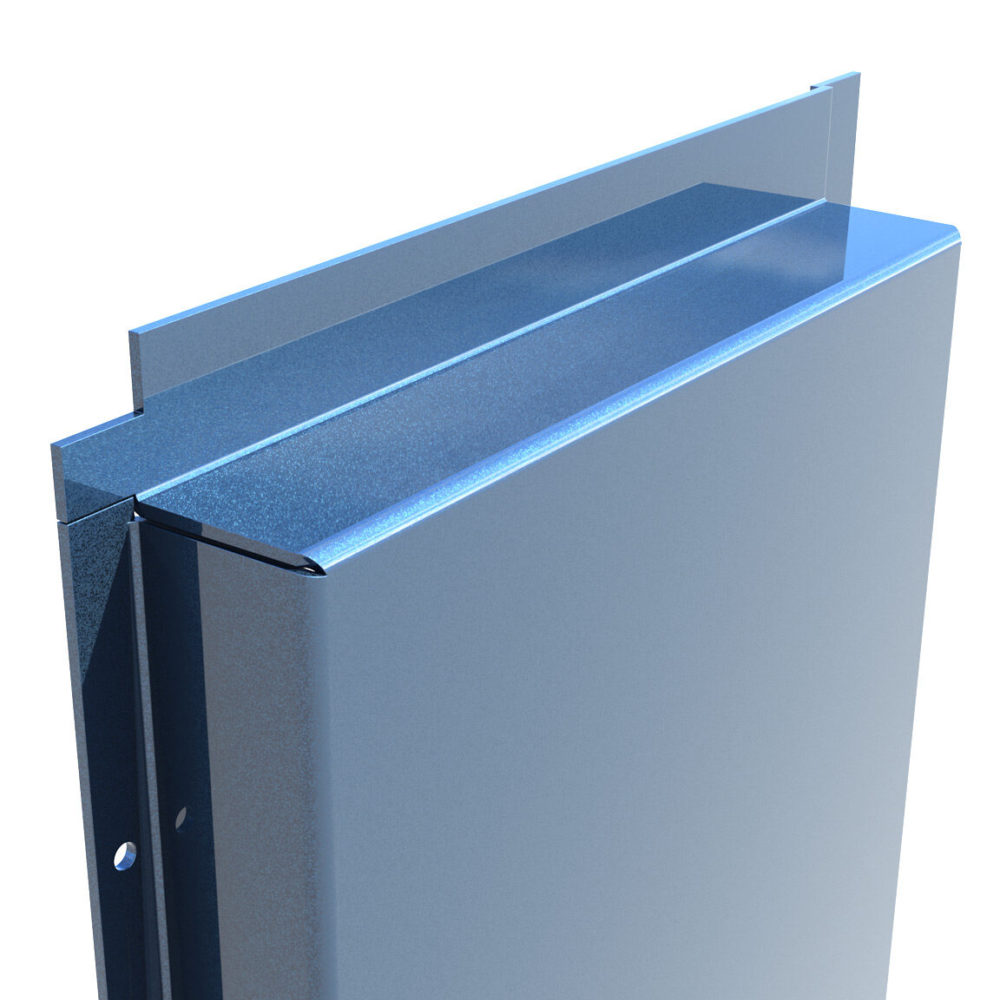

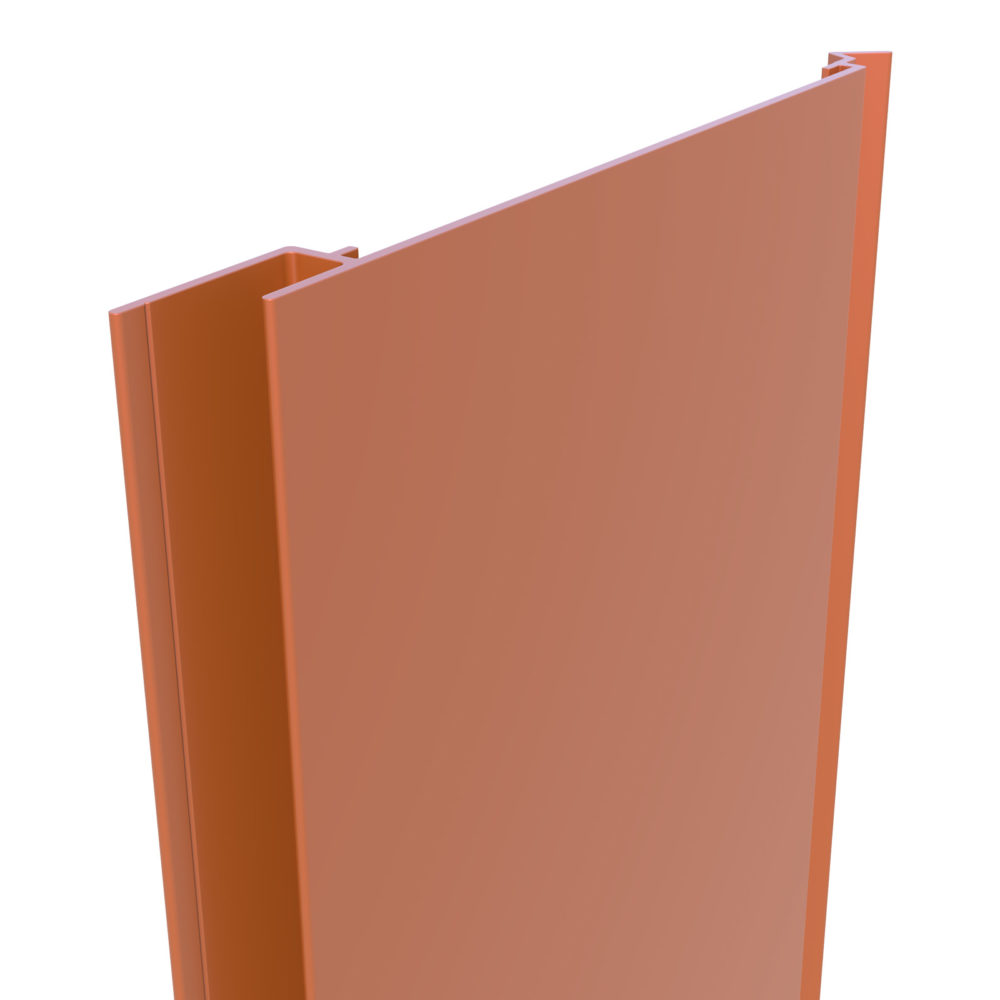

We also have constructed training walls where installation teams can come and familiarise themselves with our Optima Rainscreen Systems, and products can be tried, tested and handled prior to going on site.

IF YOU’RE AN ARCHITECT/DESIGNER

There is a huge range of materials, finishes, colours and design options, offering the specifier an almost limitless choice of products, presented in a practical and convenient way designed to cut research time for the designer and provide an in-depth technical resource.

IF YOU’RE AN INSTALLER:

Experience the range of systems and choice of materials, explore technical solutions to specific problems, iron out design details and gain an understanding of scheduling requirements. All systems can be examined in detail and real-life applications can be rigorously reviewed and tested.

No downloads in list yet.

No downloads in list yet.