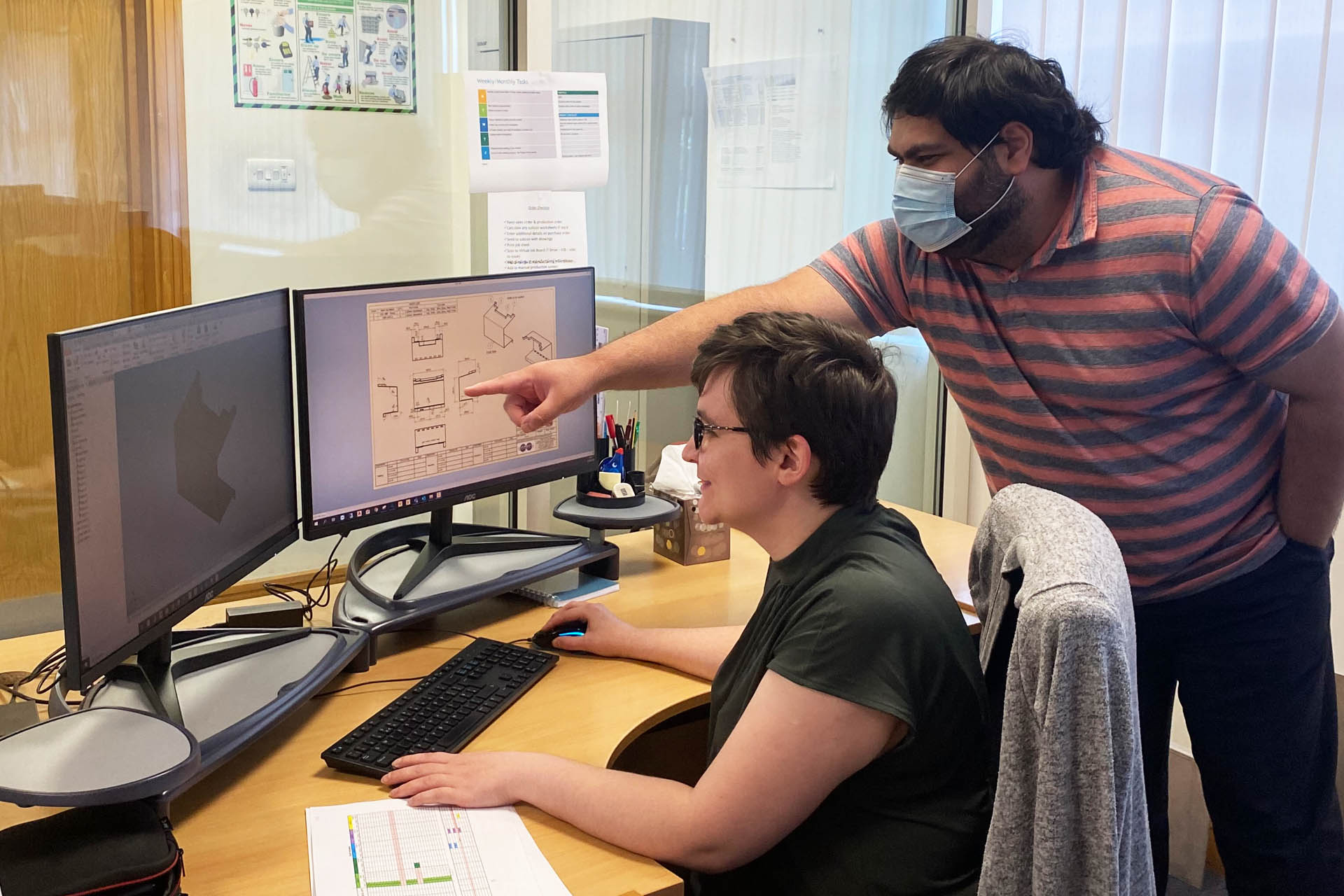

This month sees Mohammadreza Jenaban and Amy Burns promoted to Technical Lead and 3D Model Coordinator respectively, following a huge focus on the Technical Team at Sotech.

We caught up with Mo and Amy to learn more about the Technical Team and the role 3D modelling is playing in the rainscreen cladding sector.

Amy, how long have you been at Sotech?

Amy: I’ve been here nearly three years. I came from a joinery background and worked for a shop fitting company, which regularly use 3D models to visualise new floor layouts. I originally joined the design department working with customer 2D schedules in creating manufacturing information for our production team and was recently promoted to 3D Model Coordinator under Mo in the newly formed Technical Team.

What does your new role involve?

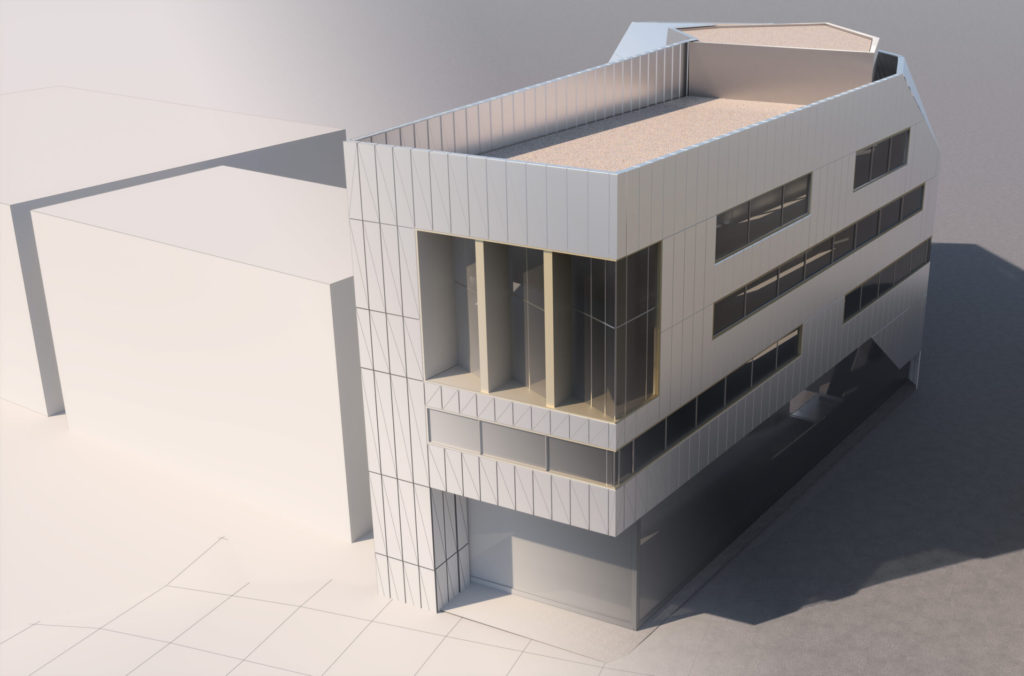

Amy: I am a 3D model co-ordinator. I work with Sotech’s customers to design 3D mock-ups / templates and samples of their design intents. When a customer comes to us with an idea for their project, it could be a student accommodation in Edinburgh or a high rise office block in the centre of London, it’s my job to make sure the panels are manufacturable, the building works in its surroundings and that customers receive their order as per their site sequence requirement. Part of the role also entails making sure site programme is kept up to date in the 3D model (the top level model).

This all means that customers can see their design intent in 3D before spending a single penny on the actual product. They then can make changes to the final design, try different materials, finishes and systems, to find the best possible build up for their unique vision and need. We bring the vision to life for our customers so they can see what their idea looks like in reality with detailed and interactive 3D models.

Mo, what has been your journey in Sotech?

Mo: I joined in 2015, under Teesside University’s Knowledge Transfer Programme (KTP). I worked in the automotive industry before that, as a Design Engineer.

My background is mechanical engineering. I’ve always loved working with 3D modelling software, especially during the design stages.

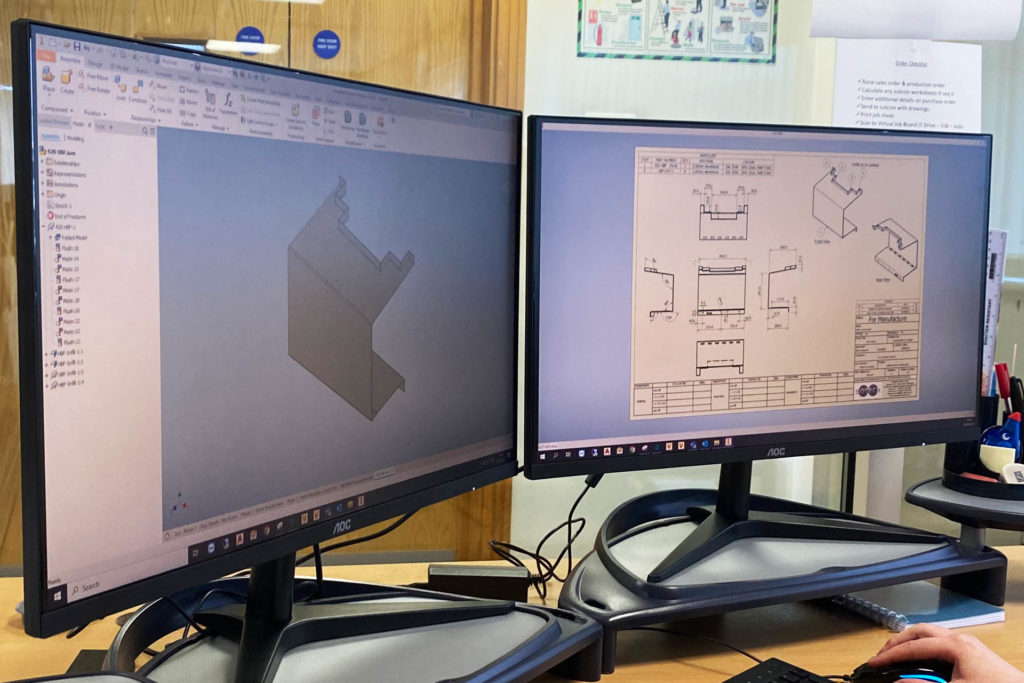

When I joined Sotech my role was to explore the various 3D modelling packages available and choose the right one for Sotech. Now, we have a unique tailored platform, and we train everyone in the technical department and drawing office on how to use the defined 3D platform.

What do you focus on now in Sotech?

Mo: Now, I lead the Technical Team in Sotech. We have always had a Technical Sales team in Sotech, but these days it is grounded much more heavily in 3D modelling, engineering and full specification project build ups using 3D modelling software. My team takes original building designs – drawings or models – and turns them into highly detailed models for FEAs (Finite Element Analysis) purposes. We also work closely with the Estimating and Sales Teams because our 3D models allow a much clearer picture of costs.

Day to day, I spend most of my time working with clients, testing and checking their designs, and advising on the best possible system, material, and finish for their original vision. Often architects or customers come to us with a vision that cannot be made in the real world. I love that. I love providing solutions to that problem. That is what engineers do: We find a way to engineer seemingly difficult structures.

For example, we recently had a request for eight metre panels on a building. You can’t even get sheets that size so we had to engineer a solution. It needed to be two pieces, made to look like one. Challenges like that are fun to solve.

But I also get involved in research projects with the Universities. We’re working on some pretty exciting R&D projects, which I will be excited to share in the future.

You work closely with customers. When is the best time for customers to engage you?

Mo: Ideally, at the concept stage. We can really help our customers to visualise their ideas in a 3D model, but the benefits go far beyond visualising the building. We can advise on the best panel arrangement, materials and finishes for their original design intent. We can show them issues with the design; where things won’t work e.g. clashes within the models and how to fix them. We can save our customers a huge amount of time and money, but we can also use our industry knowledge to recommend innovative solutions.

Amy: When we have a working 3D model, we can look at the customer’s 2D or 3D schedules or models and make sure they meet our customer’s need. When the FEA models are ready, for engineering purposes, we can help to determine which material is best for those shapes, what panel thickness will work, options for panel geometry, fixing arrangements as well as stiffening requirements. We can make the changes quickly if needed, right in front of the customer.

Mo: Another huge benefit is from a safety perspective. In the 3D model, we can even check the project boundary conditions. For example, we can advise on deflection and stress using correct boundary conditions such as applying the correct wind load or any other design load, so we know the building is designed in line with British Standards and CWCT recommendations.

You’re both really passionate about 3D modelling. What other benefits does it have?

Amy: There are so many benefits. I think the main thing is being able to turn a 2D design into a rotatable, scalable, interactive 3D model that can be adjusted and updated at the click of a button. When we see a building mocked up in this way, we can go through it in detail and flag issues – maybe the suggested material thickness won’t work, or a particular angle isn’t possible to achieve on our press machine. When we find the issues, we can make suggestions that still help the customer to realise what they can achieve in line with their original design intent.

This goes all the way through to the manufacturing stage. For example, we can make panels easier to install on site. If a panel is too large, we can suggest techniques to split it up into smaller panels but maintain the look of one large panel. This can save time and money on site when it comes to hiring cranes, mast climbers and scaffold, moveability on site and even transport. We’re always looking for ways to save the customer money, and make sure their design is safe and viable. It’s just one of the reasons we promise Sotech is a safe pair of hands.

Mo: There never used to be a fully defined process for 3D modelling at Sotech – it’s still quite new. Often, we’d receive models from customer where we couldn’t use them for manufacture. Sometimes it would take weeks to rebuild the models or fix the issues. Now, we offer this service of producing 3D templates upfront for free to our customers because it can save so much time and money all round to build a workable 3D model from the outset. Literally, if a customer gives us their design intent in 2D or 3D and tells us what materials and colours they’d like to try, we can build the 3D model and elevation for them. And once it’s approved (after a bit of back and forth of course), we know we can send the 3D parts straight to the shop floor for manufacturing.

What about the future of 3D modelling? How far will this go?

Mo: 3D is becoming more common. There is a national initiative to digitalise our cities by 2025. AutoCAD replaced drawing boards, and now 3D modelling is set to replace the 2D drawings.

We’re really passionate about 3D modelling and we want to share what we’re learning. 3D models shouldn’t be a secret. They should be shared and open in the modelling environment so we can all learn from each other and get to the end result faster: a beautiful, safe building people can enjoy.

Amy: We have a really clear vision for 3D modelling in Sotech. We want to work closely with designers right at the onset of their projects. We’d love to help our customers in modelling their designs and their buildings and run FEAs to ensure system performance and stability. We’ll show architects and customers what their building would look like using our panels in a way they’ve never seen before. We’ll render it to their original vision.

Down the line, I think virtual reality will play a role. Imagine being able to see a virtual version of your building? To walk around through the model and see it as if it were real? Shop fitting and other industries are already doing it, so I’d love to see us doing that at Sotech.

Working with Sotech:

At Sotech we use a range of 3D modelling software packages to bring the customer’s vision to life. If you’d like to work with us to see your original design intent in a fully working 3D modelling, please contact our technical team here.

No downloads in list yet.

No downloads in list yet.