The expert manufacturing team at Sotech have once again been first to market with an innovation in rainscreen cladding – a brand new system that was developed during lockdown.

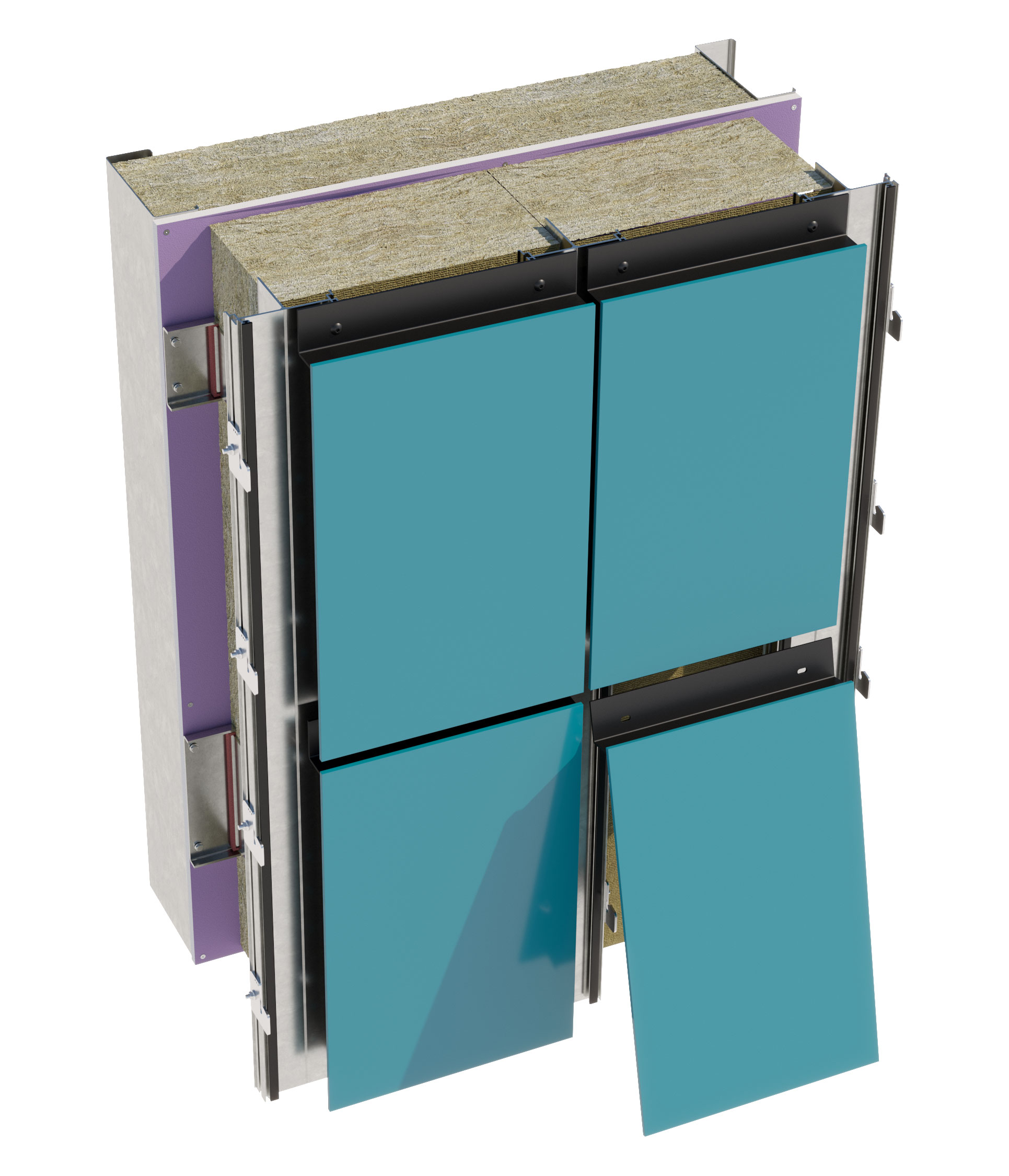

In a departure from a traditional cassette build up, the team has developed a unique way to manufacture rainscreen panels with a crisp, edge and no compromises on quality or fire safety.

Aptly named Optima Edge, this innovative new rainscreen cladding system is the only one of its kind available in the UK passing the latest 2020 fire testing standards in Element test centre in Dubai.

“We are very excited to bring this to the market”, said Lee Gravett, Product Development Manager. We identified a need and a benefit to our customers to provide a rainscreen system that provides a sharp, crisp edge appearance. With the covid restrictions, the innovation of the new product has faced many challenges however we were pleased to announce, ‘We’ve done it, Optima Edge is a success!’.

Introducing Optima Edge – the rainscreen cladding system with the crisp edge

Optima Edge is a desirable variation on the innovative FC+ secret fix hook on rainscreen model. Taking the very best of the FC+ system, the team made significant modifications to give the new system a floating panel appearance with a clean crisp, edge.

This brand-new system, available for specification now, maintains many of the benefits of Optima FC+ with additional benefit of the flat face with clean crisp edge; something highly revered and sought after by architects in the UK market.

Q&A with Graham Todd, Director at Sotech and Lee Gravett, Product Development Manager

Has Optima Edge been fire tested?

Graham:

Optima Edge has been successfully fire tested to BS8414-2;2020 and gained BR135 classification.

In November 2020, members of the team and I flew to Dubai to fire test the brand-new system on a full-scale fire testing rig.

We were confident the rainscreen system would pass the test but there was a degree of apprehension because of the new design. Where we have used a traditional cassette build up in the other tests this system is manufactured in one piece. We also opted for attaching a separate backing structure for point load studs. This meant the plate had to be self-supporting in the fire test. We were pleased (and a little relieved) to see our simulations had been correct. The Optima Edge panels work to their own tolerances and Optima Edge passed the fire test.

The maximum temperatures witnessed on the tests were significantly lower than any other tests we have performed. This was due to there being less air in the cavity because the flat panel build up is not as deep as the other Optima Rainscreen Systems and due to the thickness of material.

Why do Sotech perform full scale fire testing when they could pass with a single panel?

Lee:

Fire testing at Sotech is not about ticking a box, far from it. We want to assure our customers and the market that we are ‘A Safe Pair of Hands’. We therefore perform a full-scale fire test on a full testing rig to affirm that our panels will perform as expected in the unfortunate event that a fire takes hold.

The truth is that a single panel just does not show us what we want to know. We need to see the full rig on site. We want to see how our systems perform in a built-up environment.

As a business, it has been our policy to run large scale testing and we have always led the way on this. Other providers are moving to large scale testing now and we are grateful for the knowledge and experience we have built up over the past few decades of testing. It really shines through when advising our customers on the right system, material, and finish.

What finishes are available?

Graham:

Optima Edge was tested in a powder coat finish to provide a fire rating for an A2 material. Any improvements made to the final build up, such as a change in the finish to anodised, can only improve the fire rating of the total system.

For example, by replacing a powdered finish with an anodised finished, the system can be upgraded from an A2 rated system to an A1 rated system without requiring a new test.

There is a huge range of PPC finishes available, such as textured powder, metallic powder, anodised look, woodgrain appearance, stone effect, corten steel and zinc appearance. The nature of the panel side returns could be finished in a different colour to the panel face to give a contrasting colour.

To achieve an A1 rated system the panels can be anodised. Anodising has minimal maintenance and proven lifetime performance. (link to news story benefits of anodising)

Lee:

At Sotech, we always test our baseline products, selecting the lowest performing build up possible. It might sound counter-intuitive, but it means we have more flexibility when supporting clients. Any improvements to the material or finish can only improve on what we have tested. By anodising a panel, for example, we can achieve an A1 rating.

Has Optima Edge been tested by CWCT?

Graham:

Optima Edge has also been tested to CWCT standards. Before the tests are performed, FEA analysis is conducted on the panels, so we are already confident that the test will be a success.

Optima Edge is unique compared to what’s on the market and there is no precedent for what we’re about to test. The biggest difference we are testing is the build-up method of the carrier and the plates. In our existing systems, panels are attached using side returns. With Optima Edge, the panels are built up using stud welded returns rather than traditionally folded. We expect the panel to balloon under pressure and the studs to bear the load.

How can architects and installers review the new system?

Lee:

There are range of ways to inspect the new system. We are happy to arrange a video teams call. We can visit you on site, with samples of the system. Or you’re welcome to visit our head office in Peterlee or our new offices and showroom in Bloomsbury London.

No downloads in list yet.

No downloads in list yet.