Sotech leads the industry with full system EPDs

What is an EPD?

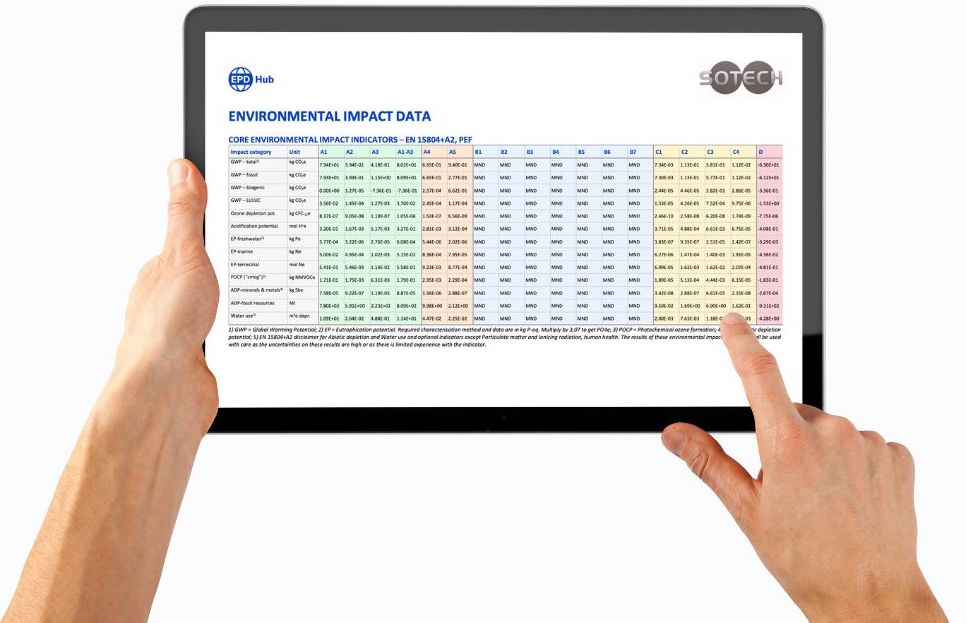

Environmental Product Declarations (EPDs) are documents that assess and quantify the use of natural resources during the production of a system; and, the environmental impact of the system throughout its lifecycle, including the end-of-life stage and how it is recycled.

The development of an EPD is based on the full Life Cycle Assessment (LCA) of a product, which measures the impact of every stage of a product life cycle, including:

– raw material extraction;

– material processing;

– manufacture;

– distribution;

– installation; and,

– end of life.

Why have Sotech opted to create System EPDs?

Within the construction sector, Sotech recognise that EPDs play a vital role in reducing carbon emissions. This is achieved by enabling comparisons of the environmental impacts linked to various materials and products allowing architects, engineers, and designers to make well-informed decisions, opting for the most sustainable solutions for the projects.

System EPD vs. Product EPDs and Why this Matters:

Sotech is one of the first companies in the sector to produce system EPDs for a complete built up rainscreen cladding system and not just a single item like a metal panel used within a system.

The purpose of this approach is to provide full transparency over the full impact of the materials, finishes and systems selected in a building’s design and enable a fair environmental performance comparison of systems.

Since most buildings are different, Sotech offers project specific EPDs based on our customers’ design intent, primary structure and wall build up, cladding zone and aesthetic considerations.

This level of transparency over carbon impact is very topical within the Net Zero Scheme, which often comes up in specifying conversations, especially when designing for schools and public sector buildings. As such, EPDs are required in green public procurement using building assessment schemes such as LEED, BREEAM and GreenStar.

In summary, while a product EPD focuses on the environmental impact of a specific item, a system EPD considers the collective impact of multiple components working together as a system and is a guide to more sustainable decision making.

Project-Specific EPDs through Team Effort

In addition to full standard system build up EPDs, Sotech can offer a project specific EPD based on client’s design intent, system performance requirements and aesthetic needs.

Creating a project specific EPD involves a tailored approach that requires careful consideration and thorough data collection. To commence, we provide a scope of the project, detailing materials, systems, and processes involved. We then break down the project into its components, identifying key elements that contribute to its environmental impact. Once the data is collected, we conduct a rigorous life-cycle assessment (LCA) to quantify the environmental impact associated with each stage of the product life cycle.

These findings demonstrate a commitment to environmental responsibility and provides a culture of sustainability within your project.

Sotech’s Approach to Sustainable Cladding Systems

Sotech is committed to producing the company’s EPDs in house, rather than using an external third party company. Sotech’s EPDs have been audited and verified by an external review company. This approach allows the teams at Sotech to become the experts on the true impact of the full range of Optima rainscreen cladding systems.

Having this full and detailed data set, coupled with the experience and in depth understanding of how an EPD is produced, allows the experts at Sotech to produce project specific EPD calculations based on a non-standard or hybrid versions of the Sotech Optima range of rainscreen cladding systems.

From our frequent conversations with architects, engineers, and designers, we know this desire is strongly felt across the sector. Safety and sustainability are the biggest topics discussed with our expert team, along with design aesthetic and functionality. This is a balancing act for our futures, and with this information, and the incredible range of rainscreen design solutions available at Sotech, it doesn’t have to be a compromise, more an environmentally informed decision.

Naturally, this is a lengthy process. Each system, material and finish will need to be assessed individually and then as a whole. The team therefore started with Optima FC+, which is our secret-fix and most popular solution. This was paired this with a PPC (powder coated) finish. The team has since continued the EPD process with the whole of the Optima range.

How is an EPD Verified?

The verification process for an EPD is detailed and methodical. Each EPD is verified in accordance with Construction Product Category Rules (PCRs), conducted by an independent, third-party verifier. It involves a comprehensive review of results, documents and compliance with reference standard, ISO 14025 and EN15804+A2:2019. The validation process encompasses critical elements such as:

The formulation and accuracy of the environmental product declaration;

The life-cycle assessment methodologies used in generating the EPD; and,

The integrity of the digital background data for the EPD.

External auditors assess Sotech’s calculations line by line to ensure the final figures match the system calculations for the CO2 match.

Additionally, it is important to highlight that an EPD is valid, typically, for five years.

Where Can I Find the Sotech System EPDs?

The final EPD documents for the full range of Optima rainscreen cladding systems are published on the Sotech web site, alongside our fire certifications and CWCT testing certificates. Customers can also find the EPDs on EPD Hub .

If you need further information on how we can help assist you to develop an EPD for your project please contact our technical team.

No downloads in list yet.

No downloads in list yet.