Rainscreen Cladding

A comprehensive overview of rainscreen cladding, the design options available and the testing required for public safety.

WHAT IS Rainscreen Cladding?

Rainscreen cladding is an exterior surface – a cladding layer – that stops the force of wind-driven water movement on a building, preventing it getting through small breaches in the surface of a building. By the time the water reaches the ‘true’ exterior wall, it has lost its drive and therefore its ability to permeate the wall, hence the origins of its name: rainscreen cladding.

Introducing the Optima Rainscreen Cladding Range

Introducing the Optima range of rainscreen cladding solutions:

Sotech design, engineer and manufacture the Optima range of rainscreen cladding systems.

From secret-fix hook on rainscreen cladding solutions to bespoke extrusion tailored to meet your design, Sotech works closely with architects, specifiers, fire consultants, main contractors and installers to specify the most suitable rainscreen cladding solution.

Our full range of rainscreen cladding solutions:

- Optima FC+ Secret Fix Hook on Rainscreen

- Optima TFC+ Through Fix Cassette Rainscreen

- Optima Edge Secret Fix Rainscreen with a Flat Plate Appearance

- Optima XTR Contour Bespoke Tailored Extrusion

- Optima IPC Pressed Plank Rainscreen

- Optima Shingles Direct & Secret Fix

- Optima XPC Extrusion Plank Rainscreen

- NEW: Optima Meadow Supporting Biodiversity

Our expert team can provide cutting edge advice on the most suitable rainscreen cladding system, material and finish for the project, as well as fire safety, design and production. Contact us here >>

Each system has been witnessed and certified by CWCT for wind serviceability and safety, air permeability, water penetration and soft body impact. The most recent tests for the Optima FC+, TFC+ and Edge also includes hard body impact testing.

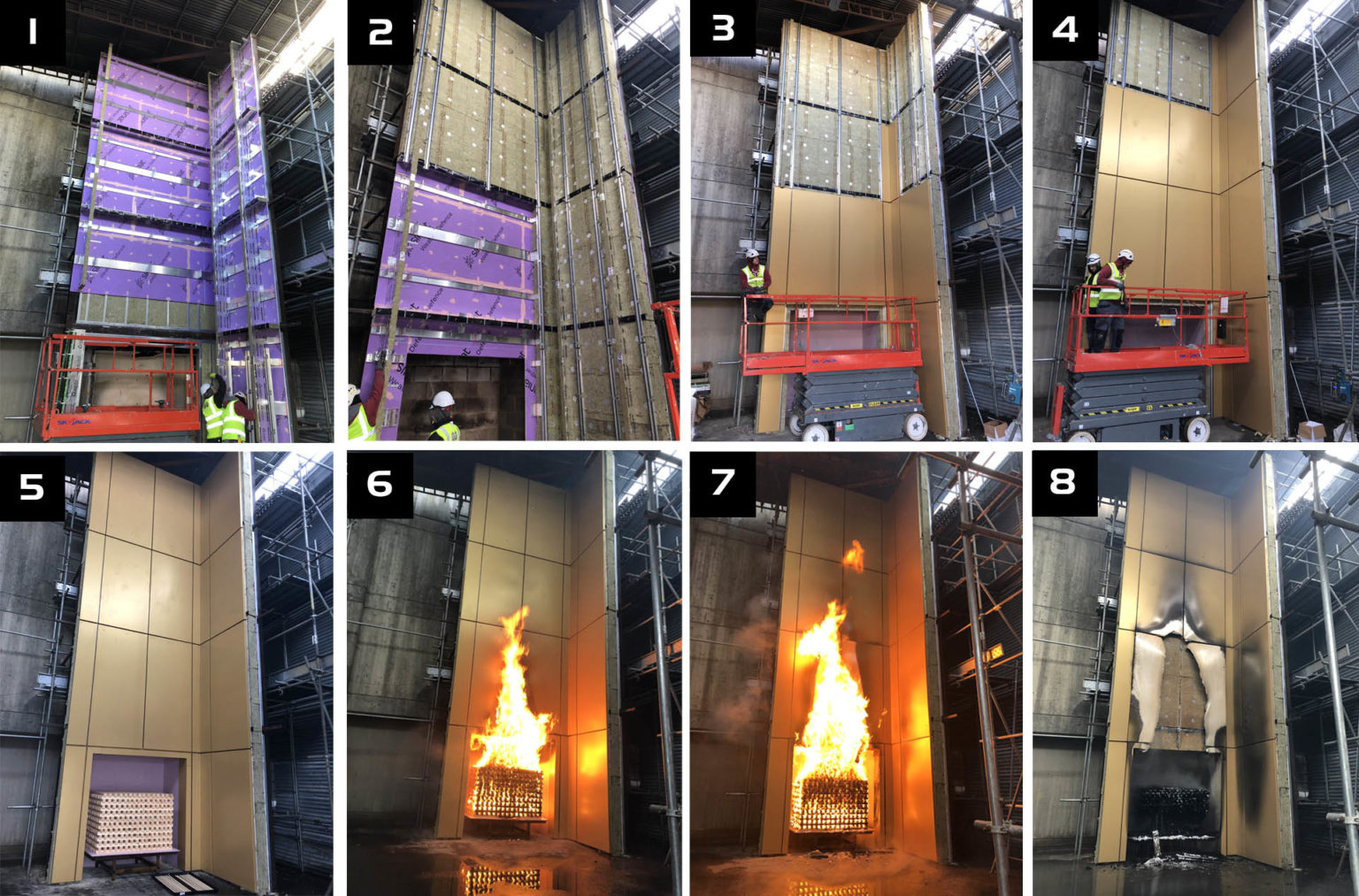

Sotech has also completed a range of full scale fire tests on its core rainscreen cladding systems, successfully fire testing to BS8414-2 and gained BR135 classification and can therefore offer true A1 fire tested systems.

This test provides a test method for determining the fire performance characteristics of non-loadbearing external rainscreen cladding systems, fixed to and supported by a structural steel frame when exposed to an external fire under controlled conditions.

Any deviations or product substitutions from that which was tested are strictly subject to BS 9414.

RAINSCREEN CLADDING SPOTLIGHT

One of our most popular rainscreen cladding solutions:

Optima FC+

Optima FC+ is our secret fix hook-On rainscreen cladding solution, and one of our most specified systems. It can be employed a diverse range of materials and thicknesses (from 2.0mm to 4mm) on one universal carrier, and its slide and lock adjustment mechanism allows for quick adjustments on site for streamlined construction.

Versatility

Sotech’s state of the art machinery allows flexibility in precision manufacturing of panels up to 3800mm x 1300mm, providing ample coverage for large areas.

The option for bespoke sizes ensures that even the most unique design visions can be brought to life. The different material options offer a balance between durability, aesthetic, and fire safety, making them a suitable choice for a wide array of construction needs.

Our latest innovation in rainscreen cladding:

Optima meadow

Optima Meadow is our groundbreaking new rainscreen cladding system, developed in collaboration with Vertical Meadow. It provides an attractive, bio-diverse and sustainable approach to urban greening by integrating plant life directly into vertical building façades. Adapting Sotech’s renowned Optima FC+ system, the collaboration introduces a groundbreaking design featuring a hinged perforated front panel, facilitating the seamless insertion of a seed membrane. The product is delivered dry to site by Sotech and integrated with irrigation systems, Wi-Fi, power, and water supplies, and activated to initiate the controlled germination process overseen by Vertical Meadow.

BIODIVERSITY

Optima Meadow provides a creative way to meet the new requirements of Environment Act 2021, through which the UK government introduced a mandatory biodiversity net gain obligation. This new obligation became effective from February 2024.

As the plants flourish and bloom over time, progress is conveniently tracked through user-friendly inspection and maintenance apps. This pioneering approach stands out as seeds are nurtured directly in place, resulting in a more cost-effective, lightweight, and sustainable system. With simplified maintenance and logistics, there’s no need to transport live plants to the site, making it a game-changer in greener construction practices.

What are the benefits of rainscreen cladding?

- Effective rainscreen cladding provides advanced protection from the wind and rain.

- Rainscreen cladding can provide enhanced thermal performance, allowing designers to create very efficient thermal envelopes to meet the highest environmental standards.

- Rainscreen cladding is simpler and quicker to install than traditional constructions and provides excellent sustainability benefits to the overall project.

- Rainscreen cladding is also beautiful. It can be used to create original shapes, unique colour profiles and award-winning designs on buildings of all sizes. It can also be used to breathe life into an old building, through ‘recladding’.

For Sotech, it is the right thing to do to complete fire testing on all its rainscreen cladding systems and in some cases, on unique build ups for added peace of mind.

What testing is required for rainscreen cladding in 2025?

The combustibility of rainscreen cladding systems has come under increased scrutiny, with responsible rainscreen cladding providers seeking improved ways to limit the spread of fire in tall buildings, including the use of totally non-combustible materials.

In recent years, Governmental advice and regulation have become more explicit on requirements for tall buildings. In November 2018 the UK government announced changes to the Building Regulations in order to implement the ban on the use of combustible material in the external walls of certain high-rise buildings in England.

Whilst fire testing is not a legal requirement on buildings over 18 meters, it is highly desirable to fire test the rainscreen cladding build up on two fronts: How likely is the material to burn, and how likely is the system to direct the fire? This provides reassurance to all parties and most importantly, it helps to ensure the building is safe for residents, in case of fire. It also helps when covering the buildings with the desired level of insurance. For Sotech, it is the right thing to do to complete fire testing on all its systems and in some cases, on unique build ups for added peace of mind.

When it comes to CWCT testing, it is not a legal requirement, but it does provide invaluable guidance that a rainscreen cladding solution performs as intended when it comes to deflection, load, and water penetration.

Sotech Fire Tested Systems

The leadership team at Sotech have always welcomed a tightening of fire standards industry wide.

For Sotech, using non-combustible materials and fixings along with a focus on full scale fire testing is the right thing to do. Safety should never be an afterthought but an embedded part of the design process of any building, especially tall buildings and buildings of multiple occupancy.

Sotech is proud to have a full range of A2 and A1 materials available. And, with the recent improvements to Optima FC+ and Optima TFC+, we can now offer true A1 systems, complete with mechanical fixings in place of adhesive. You can find out more about the options available using our quick reference guide to fire testing.

All Sotech Optima systems carry full CWCT certification and the Optima FC+, TFC+ and edge have been tested to BS8414-2. Sotech is also accredited to ISO9001:2015, iso14001:2015, OHAS18001:2007.

True A1 Fire Ratings

EUROCLASS A1 RAINSCREEN CLADDING MATERIALS

Euroclass A1 and A2 materials are non-combustible materials ideal for façade cladding on high-rise and high-risk buildings.

The Euroclass A1 fire rating is considered one of the strictest fire protection standards for building materials in the world and in 2020, we have seen the introduction of more A1 and A2 fire rated materials in Europe.

ALPOLIC A1, for example – a non-combustible aluminium composite material – was introduced to the market by Mitsubushi Chemical Corporation earlier this year. Stamped with the highly desirable European Fire Protection Class Euroclass A1 fire rating, ALPOLIC™ A1 is set to become a top material of choice for architects and installers.

Sotech is an approved supplier of the ALPOLIC A1 material and is able to provide a full range of Euroclass A1 and A2 – s1,d0 panel materials from 2mm – 4mm.

SPEAK TO AN EXPERT TODAY:

If you require advice with design detail, assistance with a specification or to discuss your project in detail contact our technical department who have over 40 years experience in the construction industry. The team is on hand to provide knowledge and support at every stage of your project.

No downloads in list yet.

No downloads in list yet.