The rainscreen cladding industry has seen a dramatic focus on testing for large scale buildings and rainscreen cladding solutions in 2020. A focus on fire tested rainscreen cladding solutions began following the tragic circumstances of Grenfell in 2017.

Sotech has been at the forefront of testing in the rainscreen cladding industry and has been performing tests of this nature since 2006. From the earliest tests of our Optima TFC system at BRE through to the most recent large-scale testing of bespoke systems in Element, Dubai and FPA Gloucester, UK safety has always been our primary concern, followed closely by outstanding design, flawless finishes and an end to end proactively managed production line.

What is Sotech’s approach to testing?

At Sotech, we design, engineer, and manufacture the Optima range of rainscreen cladding systems, including a hook-on secret fix solution, a through fix cassette solution, an interlocking plank solution and more.

Each Optima system has been tested and certified by CWCT for wind serviceability and safety, air permeability and water penetration. CWCT testing, together with good design and installation, can provide ultimate peace-of-mind that the product will deliver the intended performance.

Sotech has also completed a range of fire tests on its core systems, with the first successful fire test carried out in 2006 – Optima TFC applied to masonry wall – and in 2008 – Optima TFC fixed to and supported by a SFS wall. Sotech were first in the industry to be entered into the LPCB Red Book and were the only rainscreen cladding company to complete fire testing, long before it was required. The most recent tests to BS8414-2 (compliant to BR135) were carried out on Sotech Optima TFC+ and Optima FC+, both in the UK and Dubai.

Sotech also performs individual tests for bespoke projects, as panels vary job to job and customers value the reassurance of bespoke testing for their unique build up choices and panel sizes. For example, in August 2019 project specific testing was carried out on the bespoke extrusion for Bath Court, Birmingham, Residential Scheme. It was tested and certified by CWCT at Vinci Technology Centre.

Sotech is committed to its authentic engineering capability and the safety of the public who use the buildings. We are happy to arrange full system tests, fire tests and large scale mock-ups for our clients on request. Please click here to find out more about large scale testing.

What testing is required on rainscreen cladding in 2020?

Whilst fire testing is not a legal requirement on buildings over 18 meters, it is highly desirable to fire test the rainscreen cladding build up on two fronts: How likely is the material to burn, and how likely is the system to direct the fire? This provides reassurance to all parties and most importantly, it helps to ensure the building is safe for residents, in case of fire. It also helps when covering the buildings with the desired level of insurance. For Sotech, it is the right thing to do to complete fire testing on all its systems and in some cases, on unique build ups for added peace of mind.

When it comes to CWCT testing, it is not a legal requirement, but it does provide invaluable guidance that a rainscreen cladding solution performs as intended when it comes to deflection, load, and water penetration.

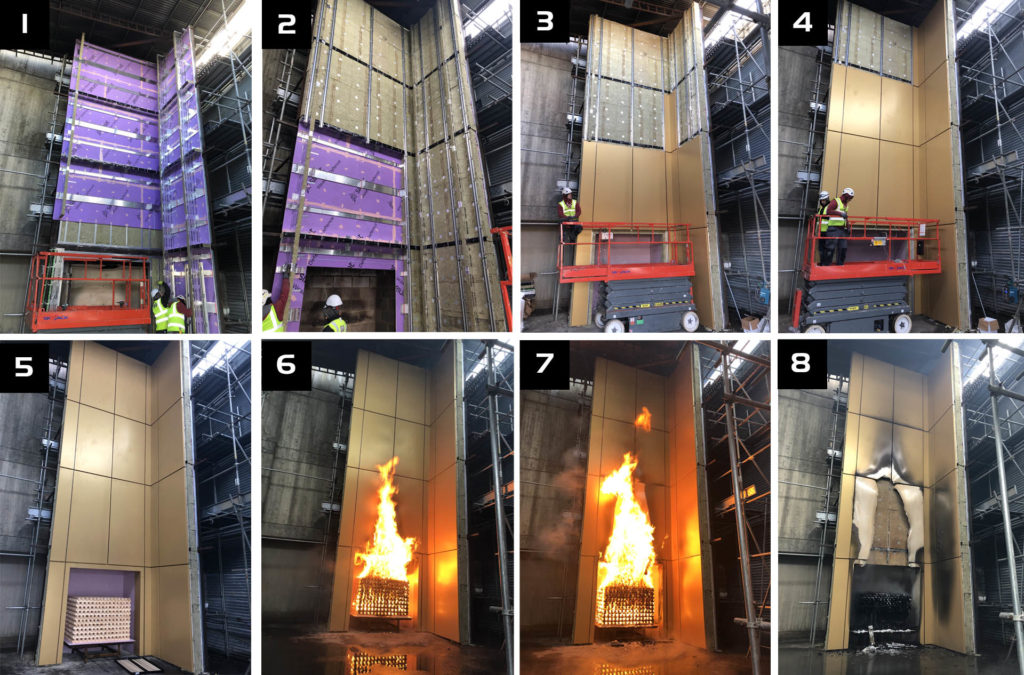

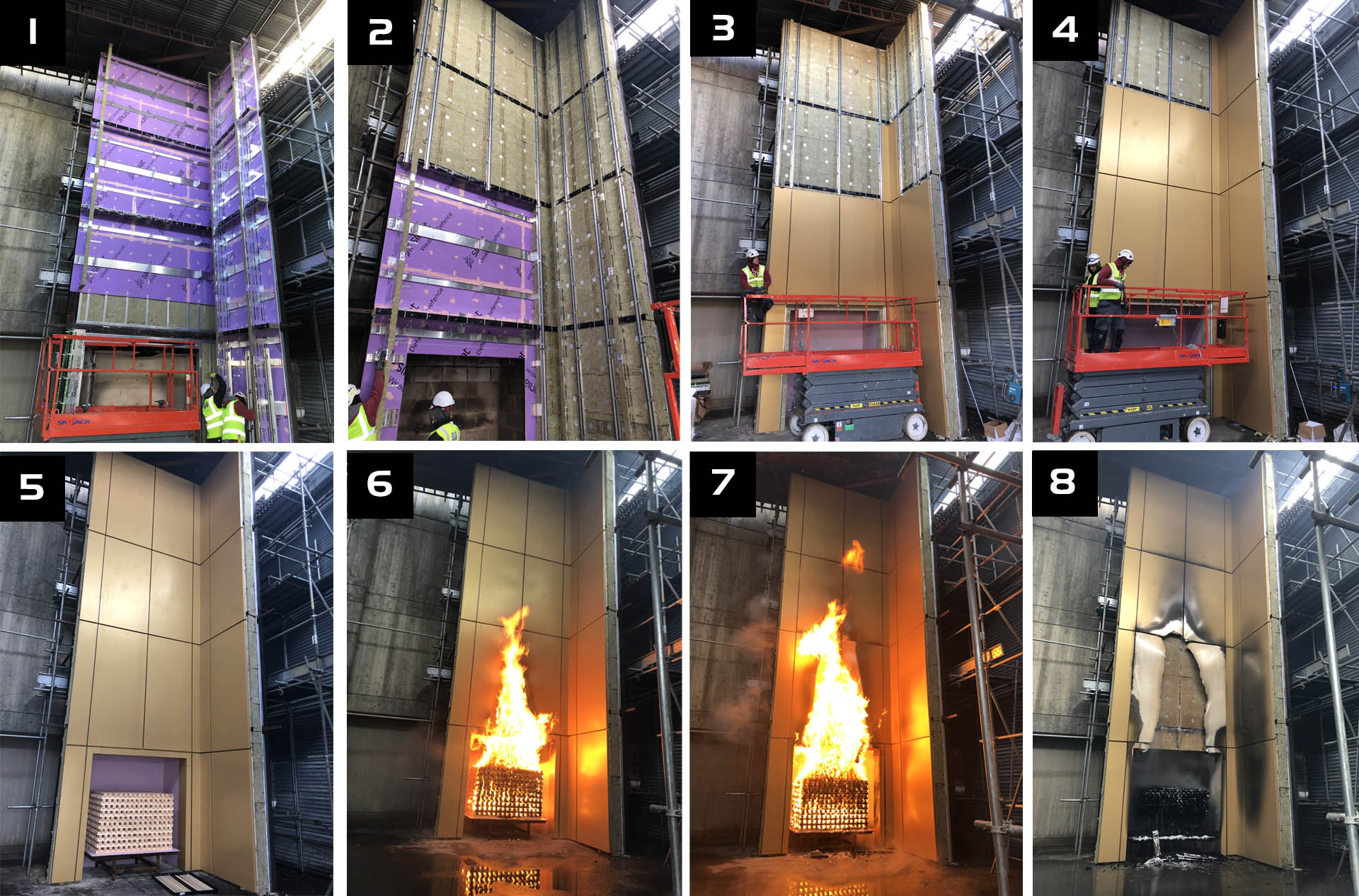

How does a large-scale rainscreen cladding test work?

The purpose of the large-scale test method is to provide data that enables the evaluation of the fire performance of the cladding components tested in combination. It is split into two parts:

Part 1: Test method for non-loadbearing external cladding systems applied to the masonry face of a building.

BS 8414-1 provides a test method for determining the fire performance characteristics of non-loadbearing external cladding systems, rainscreen over cladding systems and external wall insulation systems when fixed to and supported by a masonry substrate and exposed to an external fire under controlled conditions.

Part 2: Test method for non-loadbearing external cladding systems fixed to and supported by a structural steel frame

BS 8414-2 provides a test method for determining the fire performance characteristics of non-loadbearing external cladding systems, fixed to and supported by a structural steel frame when exposed to an external fire under controlled conditions.

Tested material is then awarded with a code A – F, depending on fire performance with ‘A’ reflecting the highest performance. Numbers are then added to reflect combustibility. For example, ‘A1’ denotes ‘non-combustible’. ‘A2’ denotes ‘limited-combustibility’.

Sotech is proud to have a full range of A2 and A1 materials available. And, with the recent improvements to Optima FC+ and Optima TFC+, we can now offer true A1 systems, complete with mechanical fixings in place of adhesive. You can find out more about the options available using our quick reference guide to fire testing.

What testing does Sotech carry out?

Sotech carries out three main types of testing:

CWCT: All Sotech Optima Rainscreen has been witnessed and certified by CWCT for wind serviceability and safety, air permeability and water penetration.

Large scale fire testing: Sotech Optima FC+ and Optima TFC+ has been tested to BS8414-2 (compliant to BR135). We have completed several successful fire tests with a range of build ups and welcome and encourage full scale system testing. Please visit our full scale testing page for information on our recent tests and to find out more about how Sotech can work with you to complete a full system fire test.

LPCB, ISOs, Quality Assurance: Sotech’s QHSE system meets the ISO 14001:2004 Environmental Management System Requirements. The QHSE system is independently inspected and accredited to the ISO 9001:2008 Quality Management System Requirements. We are also approved by LPCB in meeting the OHSAS 18001:2007 Occupational Health and Safety Management System requirements. Learn more here.

Working with a manufacturer which you know is ISO quality assured has a range of technological, economic, and societal benefits. Adhering to International Standards helps to harmonise technical specifications of products and services in order to break down the barriers to international trade, and ensure the industry runs more efficiently in general. Knowing Sotech conforms to International Standards also helps to reassure our clients that our products are safe, effective, and environmentally friendly. Find out more about sustainability at Sotech.

No downloads in list yet.

No downloads in list yet.