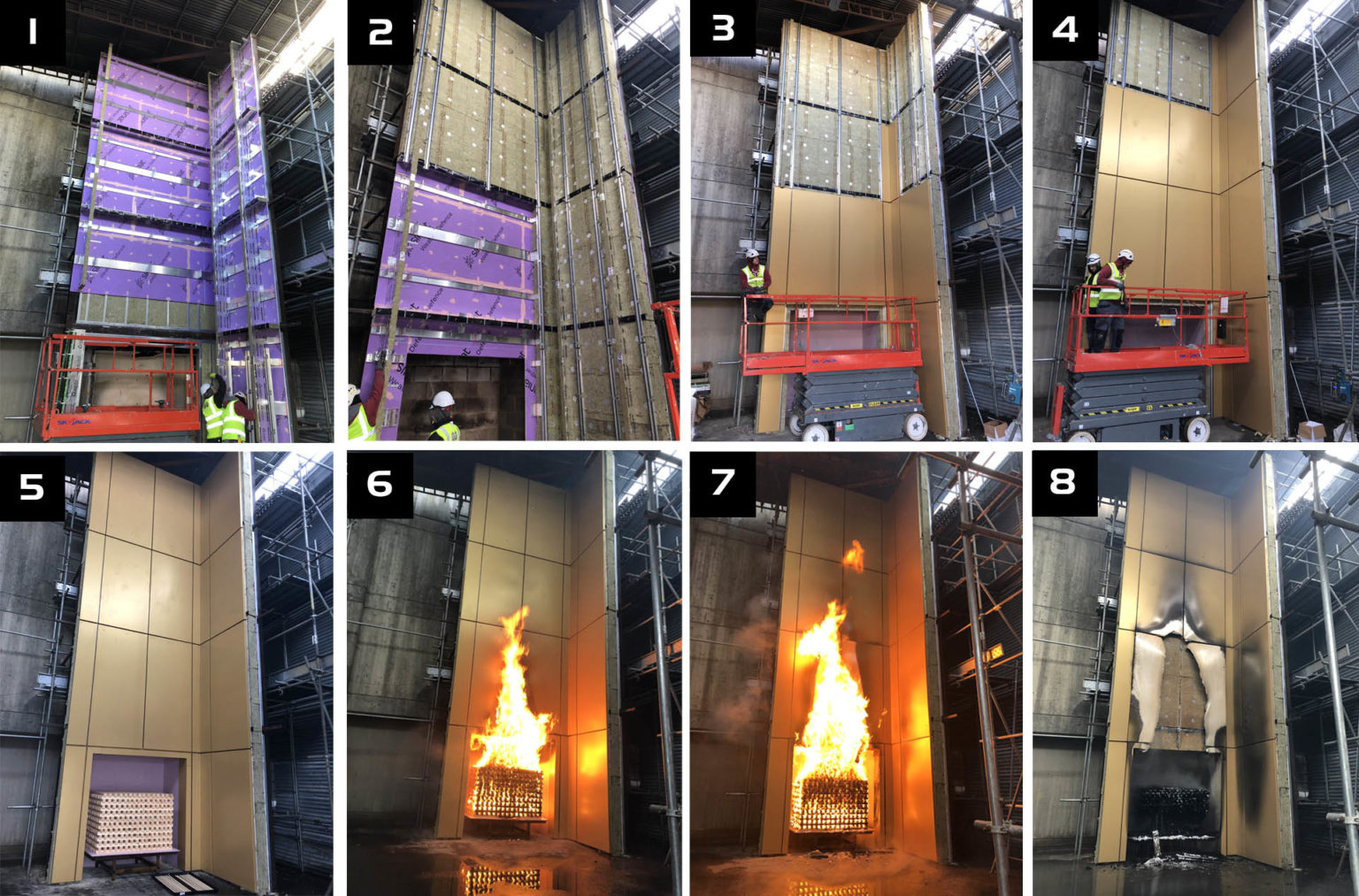

FULL SCALE SYSTEM TESTING

Full scale system testing involves building a complete model of the proposed build up.

This includes the carrier system, the material, the finish and the firebreaks – and mounting it to a 9 metre demonstration wall to test how it performs under real fire conditions.

The aim of the test is to replicate what would happen if a severe fire broke out a window in a block of flats or a story in a high rise building (above 18m).

What’s important in these tests is that the full cladding system is tested as a whole to confirm its effectiveness in slowing and controlling the spread of fire in tall buildings. For this reason, the test must assess the cavity barriers and fire stopping, the effectiveness of the construction design and the outcome of the materials specified in combination.

The PRocess of SYSTEM TESTING

There is a simple three stage process for completing a full scale fire test with Sotech and the earlier our partners contact us, the more we’re able to help in the process.

Once confirmed, a certificate will be presented to show that the build-up has passed the BS 8414 fire safety test. This fire testing certificate can then be used to gain suitable insurance.

STAGE 1

Cladding make up is specified in specification document. An expert member of the Sotech technical team reviews the specification in depth and advises on the best possible build-up of individual parts and highlights potential risks, issues and opportunities.

STAGE 2

Sotech organises a full scale test at one of the facilities around the world, booking in the test, arranging for the shipment of all necessary materials and organising the required personnel for the test. Our partners are welcome to join us and attend the test days in person or wait for the full report.

STAGE 3

Full system test is carried out, in confidence that the build up will meet the requirements of the guidance set out in BR 135 – Fire Performance of External Thermal Insulation for Walls of Multi-storey Buildings.

Learn More…

The Learning Zone plays host to innovative design workshops, CPD seminars and launch events where designers, contractors and material manufacturers can meet, evaluate and review projects and address technical issues at the very start of the design process.

We also have constructed training walls where installation teams can come and familiarise themselves with our Optima Rainscreen Systems, and products can be tried, tested and handled prior to going on site.

IF YOU’RE AN ARCHITECT/DESIGNER

There is a huge range of materials, finishes, colours and design options, offering the specifier an almost limitless choice of products, presented in a practical and convenient way designed to cut research time for the designer and provide an in-depth technical resource.

IF YOU’RE AN INSTALLER:

Experience the range of systems and choice of materials, explore technical solutions to specific problems, iron out design details and gain an understanding of scheduling requirements. All systems can be examined in detail and real-life applications can be rigorously reviewed and tested.

No downloads in list yet.

No downloads in list yet.