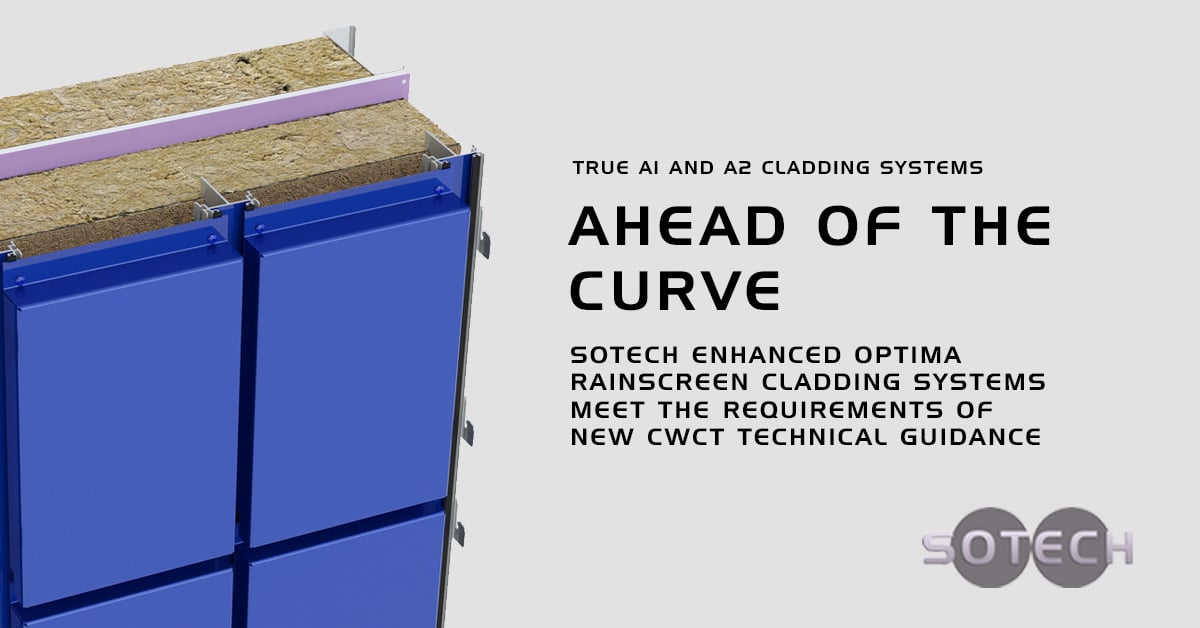

Sotech enhanced Optima rainscreen cladding systems meet the requirements of new CWCT Technical Fire Guidance due to their new and improved mechanical fixings, which replace all use of potentially combustible adhesive fixings.

In June 2020, Sotech introduced an evolution of its original Hook On Secret-Fix Rainscreen Cladding System – Optima FC+ and its enhanced Through Fixed Cassette Rainscreen – Optima TFC+.

The improved systems feature two significant upgrades that have positioned Optima FC+ and Optima TFC+ as two of the few truly A1 and A2 rainscreen cladding systems in the market today.

Mechanical fixing methods

The combustibility of rainscreen cladding systems has come under increased scrutiny. Now, more and more responsible rainscreen cladding providers have been seeking improved ways to limit the spread of fire in tall buildings, including the use of totally non-combustible materials.

In recent years, Governmental advice and regulation have become more explicit on requirements for tall buildings. In November 2018 the UK government announced changes to the Building Regulations in order to implement the ban on the use of combustible material in the external walls of certain high-rise buildings in England.

In response to these developments, The Centre for Window and Cladding Technology Technical Committee and the Society of Façade Engineering and Fire Committee have released further technical fire guidance for interpretation in relation to the external walls and specified attachments of Relevant Buildings in England.

Under clause 6.6.1 Rainscreens, the committee has advised that adhesive bonding is combustible and therefore will not meet the requirements of the regulation:

6.6.1 Rainscreen panels may require additional stiffeners fixed to the back of the panel in order to limit deflections. The number of stiffeners required will depend on the size of the panel, the design wind load and the stiffness of the panel materials. Stiffeners have typically been attached by welding, mechanical fixings or adhesive bonding. The adhesives used are combustible and as such will not meet the requirements of regulation 7(2). Such adhesives cannot be considered as seals or sealants.

Therefore, where stiffeners are bonded to rainscreen panels, the panel assembly would require testing in order to demonstrate that it achieves class A2-s1, d0 or better as required by regulation 7(2). Where the use of any panel differs from that which was tested, and previous test results are being relied upon, it is essential to confirm that the panel meets the field of application rules of the tested system. One alternative to bonding stiffeners to rainscreen panels is the use of stud welding to attach threaded studs to the back of the rainscreen panels and then bolt the stiffener to the studs.

Rainscreen panels are sometimes bonded to support rails, rather than using more traditional mechanical fixings. The adhesive used in such situations cannot be considered as a fixing or a sealant and is required to satisfy regulation 7(2).

Source: CWCT/SFE Fire Guidance

In the development of Sotech’s improved Optima FC+ and Optima TFC+ rainscreen cladding system, the leadership team decided unilaterally to remove all adhesive fixings from both systems and replace it with mechanical fixing methods, providing true A1 and A2 cladding systems.

“We are proud, as ever, to be putting safety first. Sotech prides itself on being a safe pair of hands. We will always do what is safe and what is right, long before the advice reaches requirements. That’s why we opted for mechanical fixings over adhesive fixing. It’s safer and it’s the right thing to do.”

Graham Todd, Director

Euroclass A1 Materials

Euroclass A1 and A2 materials, by contrast, are non-combustible materials ideal for façade cladding on high-rise and high-risk buildings.

The Euroclass A1 fire rating is considered one of the strictest fire protection standards for building materials in the world and in 2020, we have seen the introduction of more A1 and A2 fire rated materials in Europe.

ALPOLIC A1, for example – a non-combustible aluminium composite material – was introduced to the market by Mitsubushi Chemical Corporation earlier this year. Stamped with the highly desirable European Fire Protection Class Euroclass A1 fire rating, ALPOLIC™ A1 is set to become a top material of choice for architects and installers.

Sotech is an approved supplier of the ALPOLIC A1 material and is able to provide a full range of Euroclass A1 and A2 – s1,d0 panel materials from 2mm – 4mm.

Sotech Fire Tested Rainscreen Cladding Systems

The leadership team at Sotech have always welcomed a tightening of fire standards industry wide.

For Sotech, using non-combustible materials and fixings along with a focus on full scale fire testing is the right thing to do. Safety should never be an afterthought but an embedded part of the design process of any building, especially tall buildings and buildings of multiple occupancy.

Sotech is proud to have a full range of A2 and A1 materials available. And, with the recent improvements to Optima FC+ and Optima TFC+, we can now offer true A1 systems, complete with mechanical fixings in place of adhesive. You can find out more about the options available using our quick reference guide to fire testing.

No downloads in list yet.

No downloads in list yet.