Powder Coating: An interview with the experts, AkzoNobel.

AkzoNobel supplies powder coatings to more than 30,000 customers worldwide, on buildings and landmarks around the world, including La Sagrada Família (Barcelona, Spain); the Shard (London, UK); and the Birds Nest Stadium (Beijing, China).

The Shard, London, UK – Image Source, Pexels.com

Headquartered in Amsterdam, The Netherlands, the powder coatings business has 29 manufacturing sites in 21 countries and offices and representatives in more than 70 countries worldwide.

We caught up with the UK and Ireland Specification Manager, Naveen Sandhu, to learn more about architectural powder coating and the future of powder coated rainscreen products.

Naveen, can you tell us a bit about the company?

AkzoNobel is a Dutch owned company. We’ve been selling paint for over 100 years, largely through brands you’ll recognise like Dulux, Hammerite and Pollyfilla. I specialise in architectural powder coatings but our products span sectors, including the automotive, the architectural & construction, and the furniture industry.

AkzoNobel Head Office, Amsterdam. Image Source: AkzoNobel

I heard someone say once “We put make-up on buildings”, but it’s a little more than that of course.

Our Interpon D architectural powder coatings covers a really broad colour palette with textures and special effects available in a range from standard durable to super durable finishes.

Leeds Beckett University. Project details available here.

The advances in the industry in recent years have been immense. I would once have been laughed at for saying a metal can emulate wood, but now it’s a standard choice, and often a better one too in terms of costs, versatility and impact on the environment. We can also produce panels that look like anodised aluminium. From a couple of meters away, I’m not sure many people could tell the difference in truth.

We do some pretty interesting things people don’t always hear about too. For example, we supplied the paint for the McLaren Racing’s 2021 Formula 1 car, as well as the team’s transport, garage and accessories. Our Marine and Protective Coatings business also supplied Intertherm 50 heat-shielding for critical components surrounding the engine and exhaust.

Okay, can we talk about the science Naveen? How do you apply colours to aluminium panels? What does that process look like?

There are three key stages to powder coating rainscreen cladding materials.

Firstly, the aluminium needs to be fully pre-treated in order for the powder to adhere to the material. This is the most important part of the process. If this isn’t done correctly to a recognised standard, the paint will simply fall off in a matter of months. We’re very strict about this process and try to ensure the work is channelled to an approved applicator. These establishments are not only audited by ourselves every year but also by 3rd party accreditation test houses. This way, the supply chain can be confident that the installed parts have a robust corrosion protection.

Next, the powder is applied electrostatically either automatically or manually. The electrostatic guns emit a negative charge to the powder particles which then combines with positive electrons in the atmosphere. The particles essentially seek out and ‘stick’ to the nearest earthed surface, which should be the substrate. It’s similar to the way rubbing a balloon on your jumper creates a charge that makes it stick to multiple surfaces. Opposites attract.

The panel is then cured for 10 – 20 minutes at 180 – 200 degrees Celsius. This is a very precise process and must be done off site to ensure the constituent raw materials are fully cross linked.

Our Interpon D powder coatings meet all the major architectural quality standards including Qualicoat and GSB as appropriate to the geographic requirements.

What are the benefits of powder coating?

Powder coating is a very green process. There are no solvents in the paint. There are no heavy metals in the formulation. And the process is fairly clean too – there are no toxins or dust deposits for the people who spray it. It’s lead-free, it’s easy to dispose of, there are no volatile organic compounds (VOCs), there is a high application efficiency with up to 99% usage, it’s one coat. The list of benefits goes on.

Interpon is the first global powder coatings brand to offer an Environmental Product Declaration (EPD) and we’re immensely proud of that. Sustainability is a huge part of our strategy; it’s deep in our core values

The EPD certificate is valid for five years. It includes a life cycle assessment looking at the traceability of raw materials at each stage of the formulation , manufacturing and application process to determine how they affect the carbon footprint of the finished product.

The renewed EPD for our Interpon D range of architectural powder coatings (D1036, D2525 and D3020) lasts until 2023. In 2024 – 2029, we’re hoping the EPD will show we’ve reduced our contribution even further, making powder an even more desirable selection.

You can read more about this here.

More and more of our clients are asking for this, especially the large blue-chip companies which are now being targeted on green buildings. There has been a rapid increase in the last 18 months.

Powder coating is also extremely durable. We guarantee 30-40 years of performance with an enhanced polyester powder coated finish, depending on the location of the building.

The versatility in terms of finishes is another huge benefit of powder coating. In the past, powder coating was perceived as flat or dull, with a limited range of colour options. Think greys, whites, browns. But the industry has evolved a huge amount. Now, an architect can select from an almost endless selection of powder coating finishes and effects (1000+), with viable alternatives to anodising, GRC, and terracotta.

The timber range is coming too. Architects looking for a wood-like finish at a more affordable price with more longevity can now consider aluminium as an option. A huge driver here has been safety. Wood, naturally, poses more of a fire risk and people want to build safe buildings that occupants trust.

Wood Effect. Image Source: AkzoNobel

It’s the same for concrete. People would have laughed at the idea of aluminium replacing concrete as a material. But it’s happening. We’ve completed numerous projects from the stone effect range, with the architect opting for the more lightweight, more versatile material, that can also be handled on site with less machinery, and installed in a much swifter manner. Typically, you can save over 50kg/m2 by using powder coated aluminium vs natural concrete materials. This subsequently ensured the amount of supporting structure required is significantly reduced, as does the total carbon footprint of the envelope.

In short, a powder coated panel is striking, green and cost effective. It is becoming chameleon like in its ability to mimic various materials.

Stone Effect. Image Source: AkzoNobel

You mentioned fire safety there, can you tell us: how safe IS powder coating?

Fire safety has become a huge topic in rainscreen cladding and in powder coating, and rightly so. Every material, every build up is being considered which much more scrutiny. We take fire safety very seriously at AkzoNobel and we’ve invested heavily in understanding how materials perform in different situations, looking at full scale tests, scrutinising how powder performs vs alternative aluminium finishes such as anodising and pre-coat, and really getting into the details.

In short, what we’ve found is that there is negligible differences in how powder coated rainscreen panels and materials perform verses anodised panels and pre-coat aluminium. We’re working hard to educate our clients on this so they can work with insurers to approve their specification.

We want to move away from A1 and A2 classifications in our language. We want to look at the details under the classification and make sure it’s safe and people understand what it means.

If a guarantee covers a product for ten years, say, it’s important to look under the hood and ask “What exactly is covered under that guarantee”. The details don’t always match expectations.

Ultimately, providing the system is specified, configured and installed correctly, you have safe cladding, irrespective of whether it has an A1 or A2-s1,d0 classification.

More information can be found here.

Naveen, what trends are you seeing in architecture this year?

Covid had a huge impact on our industry. It’s taken a while for people to adapt to the new situation. Slowly but surely, however, people are re-emerging. It’s clear to us that architects and designers – creative people – love to collaborate. We see it through the whole supply chain in fact; people wanting to meet in person, in a room, to plan their projects, develop creative solutions to problems and work together. Ultimately, the nature of our product is that it’s very tangible. People love to pick up the panels, to inspect the finish and get a real feel for it. So in recent months, we’re seeing a lot more people booking on for in person CPDs and face to face meetings.

Zoom and Teams were brilliant. They still are and we often speak to clients online. But you can’t beat a handshake, a coffee and an ideas session in person, can you?

We’re also seeing a push to more nimble product selection and production, with more and more construction managers opting for modular, off-site construction. It’s safer, it’s less risky and it’s more cost effective. This means powder coated panels and metals like aluminium and steel are being selected over concrete and wood.

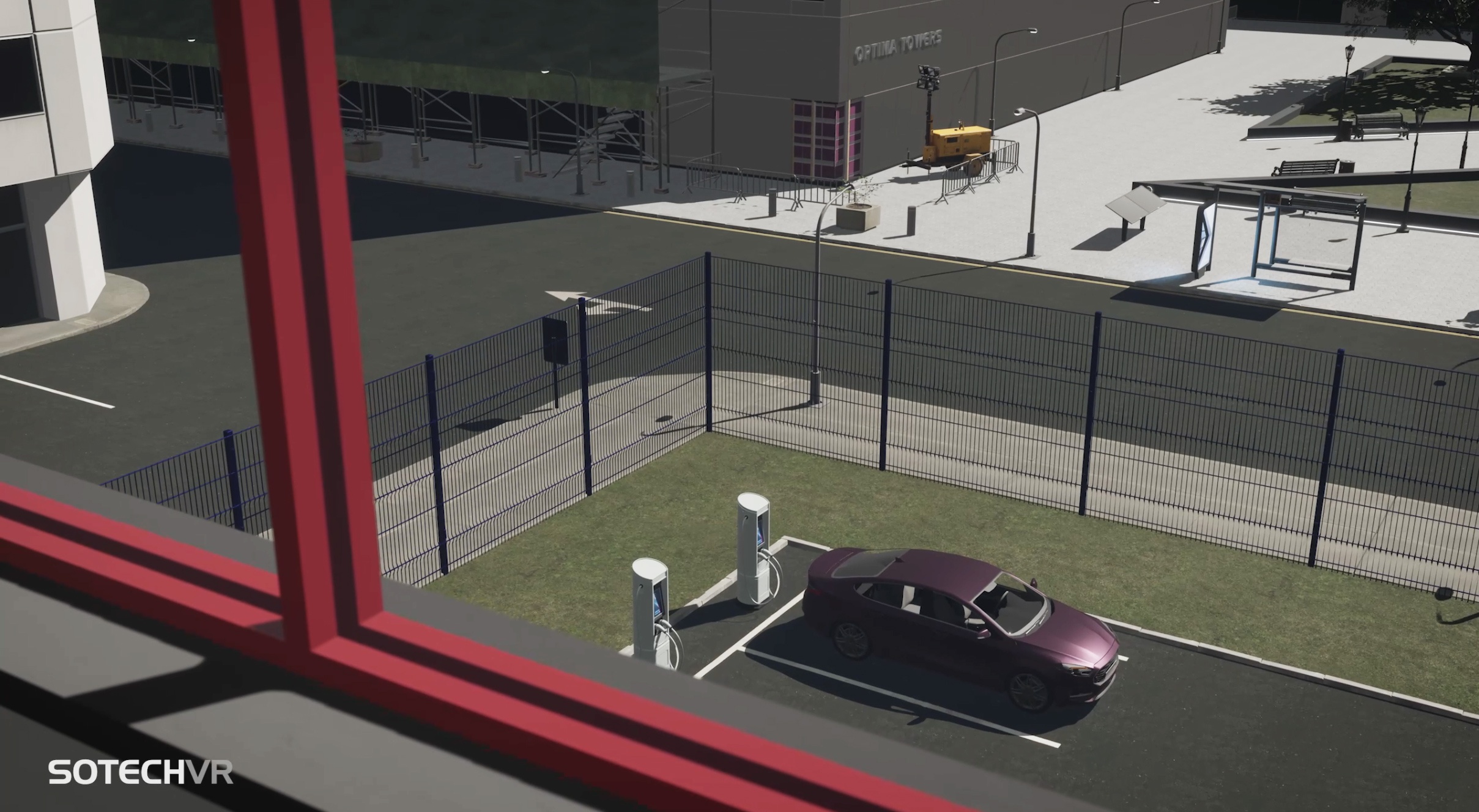

The virtual reality angle is interesting! I know Sotech has invested heavily in VR and we’re loving being part of that process, contributing our colour cards to the virtual build up options. Architects and designers don’t just want a colour card. They want to see the build up. They want to see a mock up. VR is helping this immensely when travel isn’t an option. It’s kind of fun too, isn’t it.

The thing that remains constant here is that the sooner the customer engages us in the projects, the better. That way we can talk about what will work, we can specify exact colour matches, we can be part of the solution.

Can you tell us about your relationship with Sotech?

We’ve been developing our relationship with Sotech over a number of years. Sotech doesn’t do the ordinary! They do customised projects really, really well and we align strongly with that. We want our work to stand out and we love working with Sotech to push the boundaries of what’s possible for powder coated rainscreen cladding panels and facades.

Science Engineering and Environment Building Salford University. Full project details here.

For example, the Leicester City training ground is an excellent example of this. We were approached to create a corten – copper style finish, which is quite complex. What we developed together looks outstanding. We had to use a number of subcontractors for this project, with it being so large, and it took a lot of project management to make sure each contractor used the same batch of paint. This was essential for consistency of colour. We do a lot of work like that, behind the scenes and I know the teams at Sotech do too.

We have produced some incredible buildings that have been specified with Sotech’s award winning rainscreen cladding systems.

For example, there is the 2020 Façade Award winner Leeds Becket University, the brand new Science Engineering & Environment building at the University of Salford and the very impressive Leicester City FC Training Ground. We have also collaborated on Plot C1 New Bailey, which is on the shortlist of the upcoming 2022 Façade Awards for best use of a rainscreen system using aluminium.

Leeds Beckett University. Project details available here.

Science Engineering and Environment Building Salford University. Full project details here.

We look forward to continuing our work with Sotech for many decades to come.

![[Work in progress] Ferry Lane, Walthamstow](https://sotech-optima.co.uk/wp-content/uploads/2019/08/IMG_9805-600x600.jpg)

No downloads in list yet.

No downloads in list yet.