Over 9,500m2 of the brand new Optima FC+ Anodised Aluminium has been used in the ambitious completion of Kelaty House, a towering student accommodation and hotel in Wembley London.

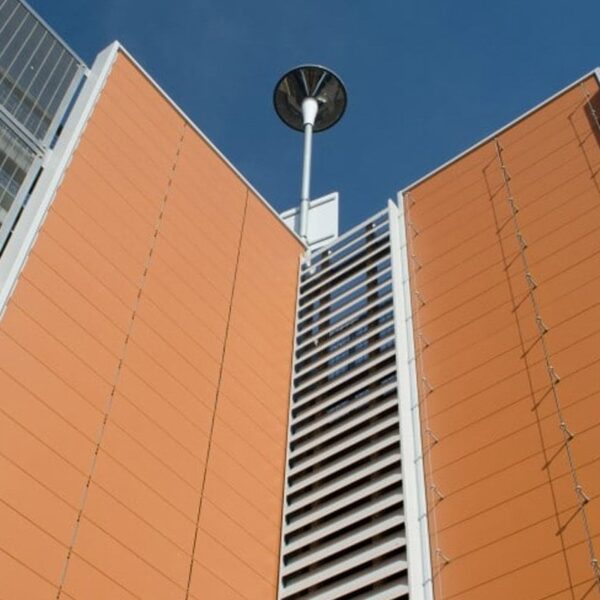

With three different surface finishes – matt, gloss and perforated – this stunning project brings together numerous wins for the Sotech team and their wider supply chain, not least the captivating tree designs visible on the finished project, created by specially perforated panels.

As you can see from the pictures below, the perforated panels have been carefully orchestrated to form the highly original tree silhouettes, visible from quite a distance on the project, which is made up of five separate high-rise blocks.

Standing back to view this building, an onlooker can’t help but look up and down the full height of the building, following the shape of the branches.

Sotech manufactured hundreds of panels for the scheme on the Salvagnini automatic panel bender, achieving maximum precision. Before the first delivery was made to site in Spring 2020, the panels were stacked and shipped to Holland to be anodised by our anodising partner, Alumet, these were then returned to Sotech and shipped to site.

Aluminium is one of the most durable and versatile of metals, anodising enhances aluminium and its environmental virtues. It is exceptionally recyclable, requires minimal maintenance and has proven lifetime performance. Due to the nature of the anodising process and the tight quality controls on both the aluminium and the surface treatment, anodising has a homogeneous (matching & consistent) appearance. Anodising enhances the natural qualities of aluminium further; it permits a strongly contemporary finish with incomparable corrosion and abrasion resistance.

It has been a complicated project to complete, not least because of the logistic coordination, but also because of the challenges caused by Coronavirus and the lockdowns, both in the UK and on the world’s borders.

All teams across the full supply chain, from material supply and manufacturing through to anodising and installation on site, everyone had to work closely together to follow the guidance, whilst keeping to tight project timescales.

Sitting in the Wembley Park regeneration area, within the immediate vicinity of Wembley Football Stadium, Kelaty House will include 300 bed Apart Hotel and 600 bed student accommodation arranged within five separate buildings ranging in height from 4 to 13 storeys.

Kelaty House has since been shortlisted for Best New Build with Conneely Façade in the 2022 Facade Awards UK.

Project name: Kelaty House Location: Wembley, London Sector: Student Accommodation & Hotel Installer: Conneely Group Main Contractor: Watkin Jones Architect: Falkner Chester Hall

Testimonials

Jamie Brown, Estimating Manager

“To date, this is one of the most exciting projects I have been involved in. This incorporated many new landmarks for Sotech as a company, including the first project to use our new and evolved Optima FC+ system and the first project to incorporate a new supply chain to help deliver the project. It was a challenge at tender stage to offer something that met both the design intent and budget given the specialist finishes selected, but working closely with our partner Conneely Group, we managed to meet both criteria. Stunning example of just how key close collaboration from all parties is.”

No downloads in list yet.

No downloads in list yet.