The Sotech Modelling Environment

A comprehensive introduction to Sotech’s modelling environment, routes to manufacture, and the best option for manufacturing your chosen rainscreen system, the design options available and the testing required for public safety.

Sotech’s approach – From Idea to Manufacture – Your Facade Partner at Every Step

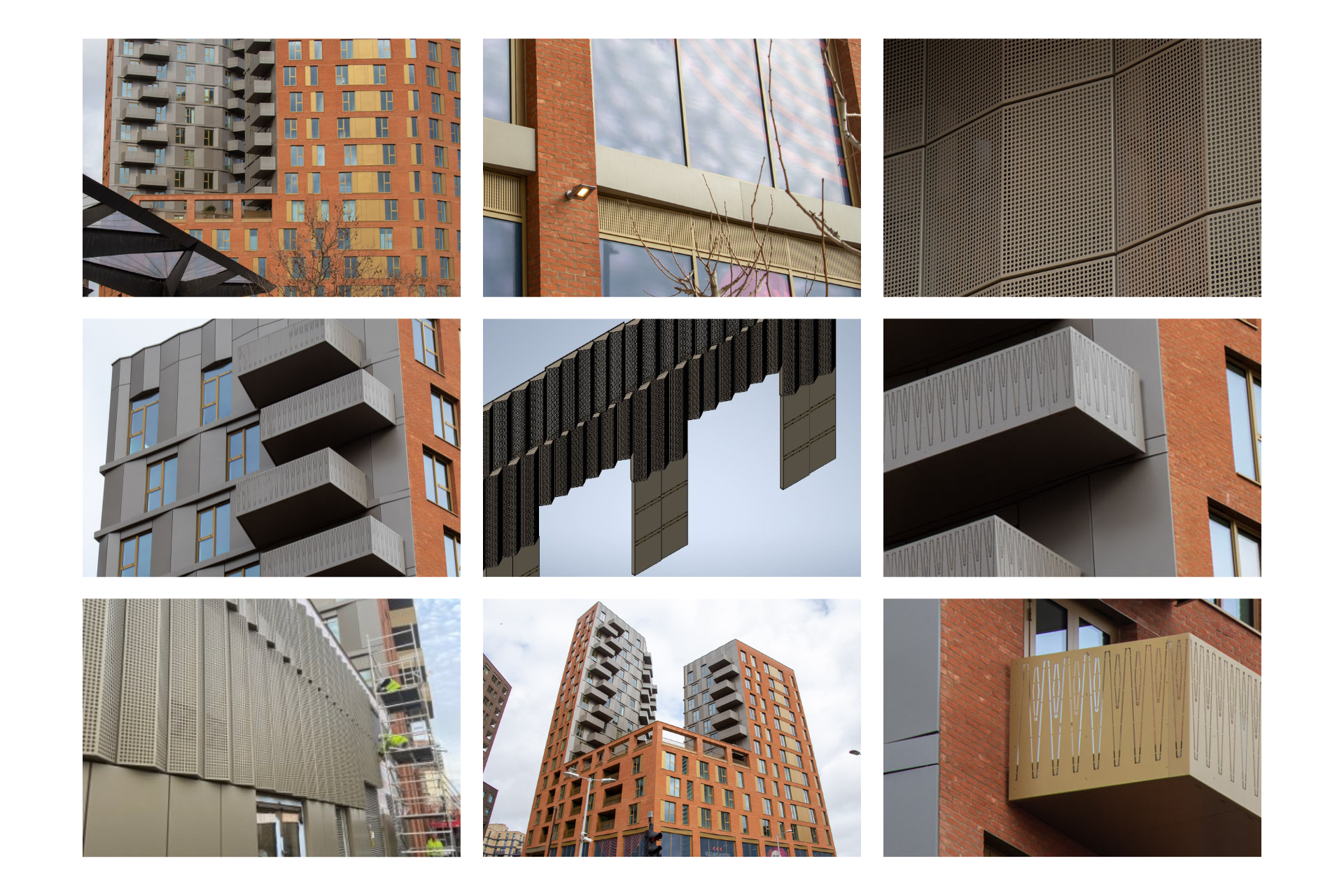

For over 40 years, Sotech has partnered with architects, contractors, and installers to bring complex façade designs to life — from first sketch to final installation.

From the moment an architect or contractor engages with our team, we share decades of technical knowledge, cutting-edge tools, and hands-on experience to ensure every panel is engineered for precision, performance, and aesthetic appeal.

Work with us to help shape your next project, advising on the best system build up for the job, working through challenges, and ensuring the design meets your vision, and is safe, sustainable and long-lasting.

Project in Focus:

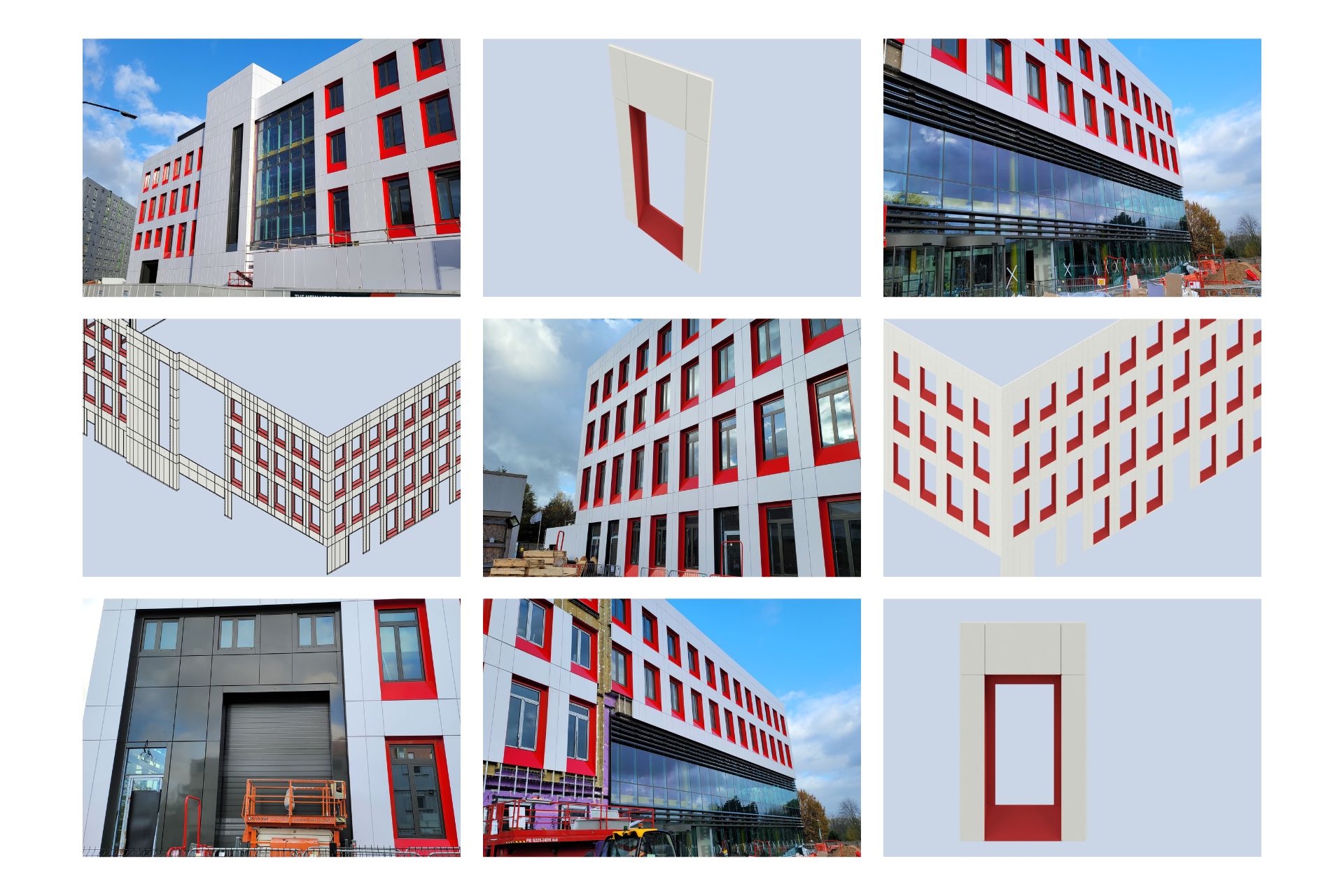

Nottingham Trent University Art and Design Building

Grounded in creative collaboration and technical precision

An example of great collaboration can be seen at Nottingham Trent University’s new Art and Design Building. Using Sotech Optima TFC+ and Optima IPC systems, Sotech worked closely with the design team to overcome complex beacon geometries, supported by Finite Element Analysis. The result is a bold, high-performance façade that reflects the creativity within the building.

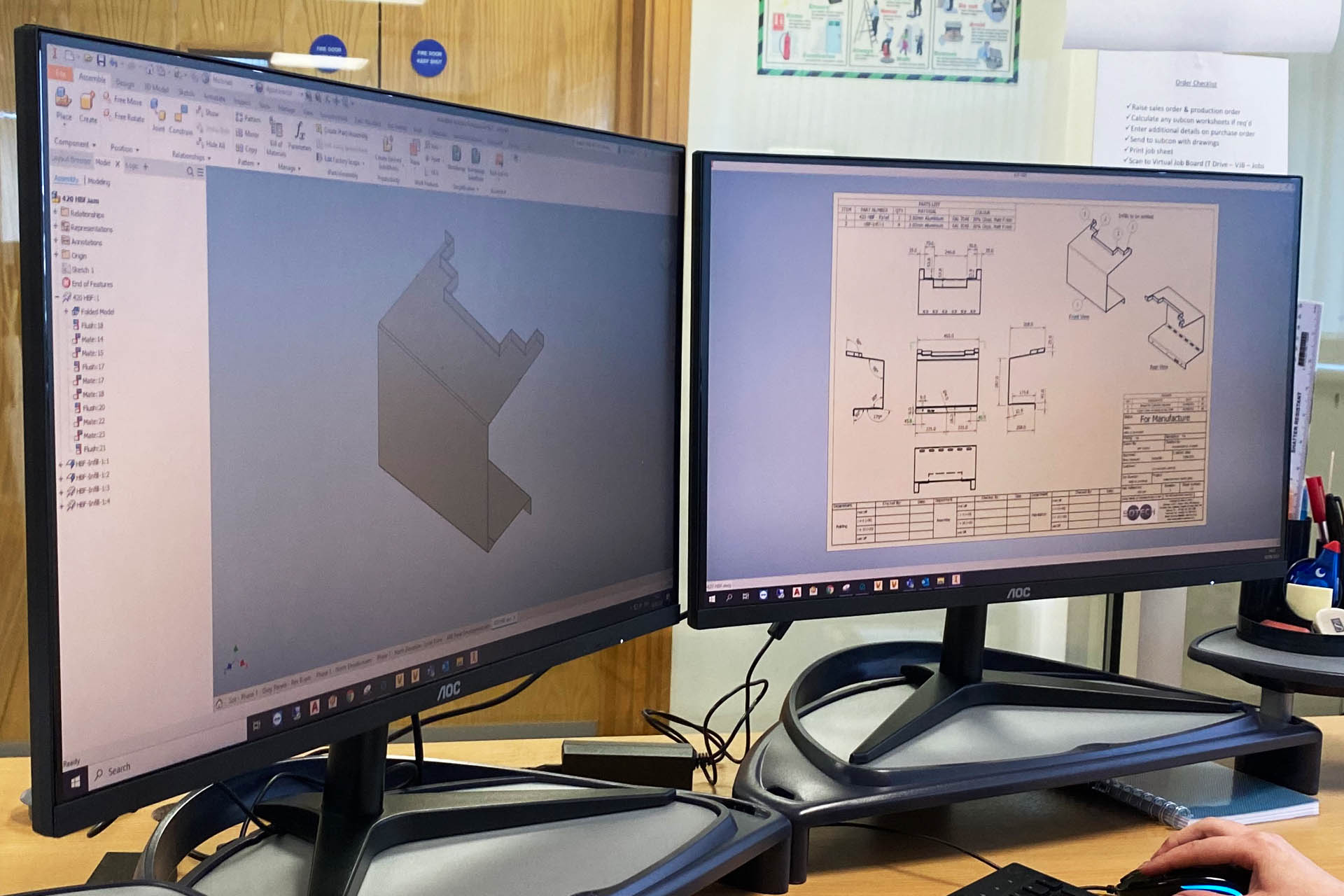

“At Sotech, every single project – whether using our standard CWCT-tested systems or a completely bespoke façade design – requires manufacturing-ready drawings, which we produce in house. The way information is supplied can dramatically impact project speed, cost, and even outcomes on site.”

Mo Jenaban, Technical Lead at Sotech

Sotech’s collaborative approach to manufacturing:

Why early engagement in rainscreen specification matters:

Whether you have a sketched layout, a detailed BIM model or a full set of 2D elevations, contact our team early in the design process and we will help by:

- Spotting risks before they become issues – saving time, budget, and stress later on.

- Recommending system types and configurations that align with performance and aesthetic goals.

- Advising on materials and finishes – from premium materials and sustainable options.

- Collaborating with our design team to test ideas, optimise layouts and ensure feasibility before anything hits the factory floor.

“It’s a true collaboration. We’re not just reacting to drawings. We’re actively advising, improving and helping our clients deliver on their design goals.”

Amy Burns, 3D Model Coordinator at Sotech

Featured above, we can see early production for feature panels perforated with strawberries for ‘One Strawberry Place’, creating a unique and meaningful façade that reflects the building’s name and character. This bespoke design not only enhances the architectural appeal but also demonstrates the versatility of our perforated metal solutions.

What are the quickest routes to manufacture?

Standard panels

What is the quickest route to production?

Pre-populated order sheets:

For our CWCT-tested standard systems, using pre-populated order forms is the most efficient path to production.

These order forms let us recommend the best system build-up for your project — reducing revisions and accelerating manufacture.

“A huge benefit of pre-populated order sheets is that we can recommend the best build up for your project. Sometimes customers select systems that look good on first glance, but aren’t the most effective choice for the project.”

Amy Burns, 3D Model Coordinator at Sotech

Bespoke panels

What is the quickest route to production?

3D model collaboration:

If you’re looking to specify a bespoke rainscreen cladding system – such as a complex perforated facade or curved panel layouts – then using 3D Model Collaboration is the most efficient method.

Our 3D modelling process focuses on manufacturability. Using Autodesk Inventor and our system-specific templates, we collaborate directly with customers to build fully manufacturable models before a single panel is cut. This ensures that by the time designs reach our production team, they’re accurate, efficient, and ready to go.

We also support BIM (Building Information Modelling) workflows to improve collaboration during the early stages of design. While 3D modelling and BIM are closely related, they serve different functions. BIM models (typically created in Revit) provide critical design intent and data, whereas Inventor models are optimised for production and precision manufacturing.

“Imagine being able to pick up and review every detail of your cladding system and be confident that it can be manufactured exactly as designed. That’s the benefit of working in 3D-we can spot challenges early, optimise panel layout, and move quickly into production.”

Mo Jenaban, Technical Lead at Sotech

Introducing the Sotech Modelling Suite

Sotech has developed a technical infrastructure designed to support clients from concept to manufacture:

3D Modelling with Autodesk Inventor

3D modelling is a vital part of our design process, helping to transform complex architectural visions into practical, buildable solutions.

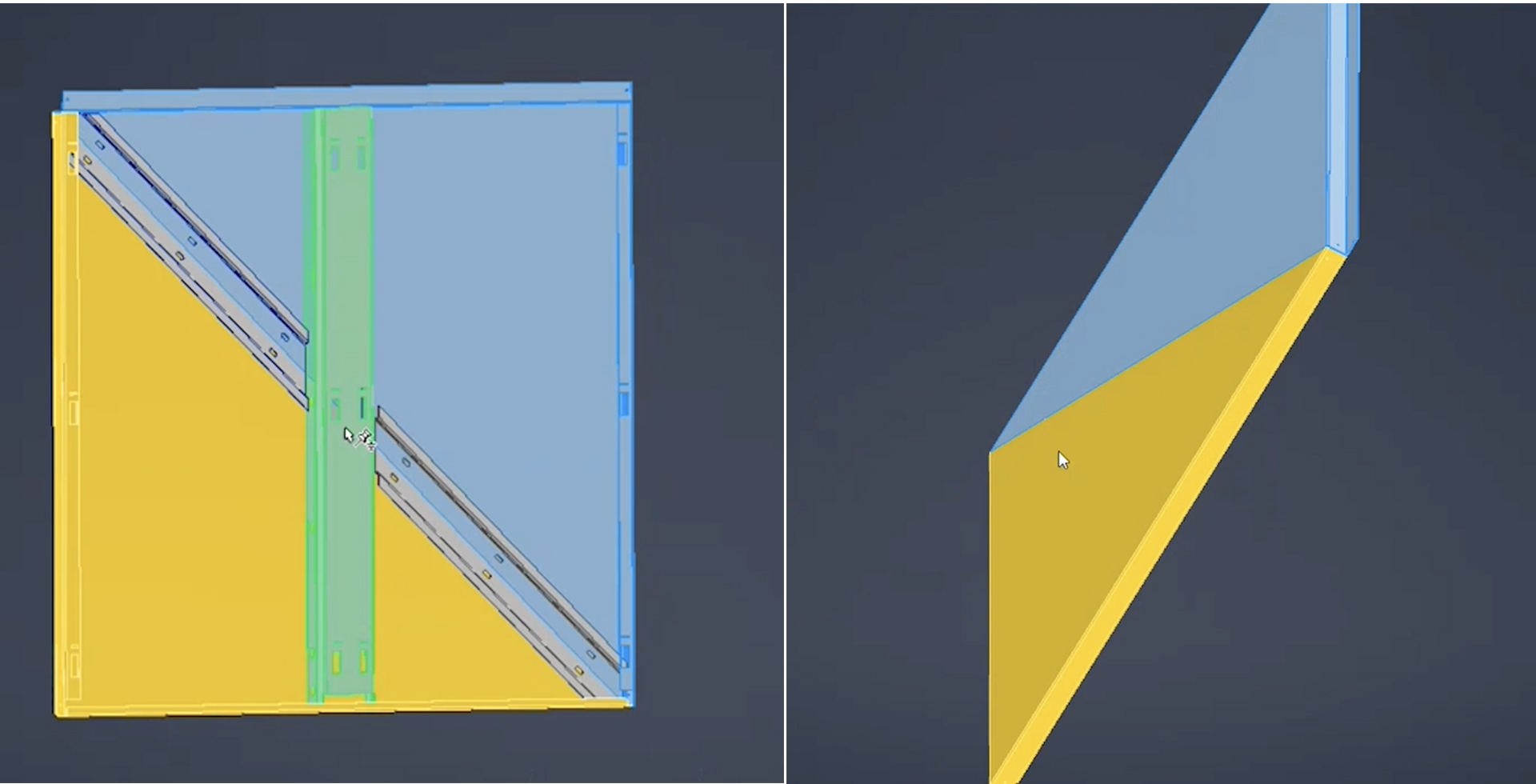

On projects such as One Ashley Road and the University of Salford’s SEE Building (shown below), detailed digital models allowed us to test geometries, refine panel sizes, and run performance simulations long before manufacture.

This collaborative approach not only reduced the need for costly physical mock-ups but also flagged potential challenges early, ensuring smoother installations on site. By providing clients with accurate visualisations and manufacturing schedules, 3D models give everyone confidence in the design, cut down on risk, and save valuable time and budget – all while keeping the architect’s vision intact.

From the earliest stages of a project, we therefore work directly with architects, contractors, and consultants in a 3D modelling environment to develop fully manufacturable façade designs.

We’re able to simulate how panels interact with subframes, accommodate openings like windows and doors, and integrate complex detailing such as perforations, returns, and curved elements.

This method results in a smoother transition into production, fewer surprises on site, and better overall project outcomes.

Use pre-populated order sheets for a quick and efficient path to production.

- Fully manufacturable models

- Designing for complexity

- Models simulate how panels interface with substructure

“Sometimes we’re tooling up within 24 hours of receiving the job sheet. That’s the power of working together in 3D. When both teams are aligned, things move fast.”

Amy Burns, 3D Model Coordinator at Sotech

Project in focus – One Ashley Road:

Here, the hexagonal style of the building meant adaptations were required to manufacture and install the unique pattern and shapes of both the ground floor soffits and the perforated panels. 3D models were created by the Sotech team to perfect the final panels before manufacture. This required a lot of design collaboration with our client CCS Façades.

BIM Objects

Using accurate BIM components ensures that what’s drawn is buildable, helping to avoid rework, delays, and on-site surprises. Our BIM objects are rich in data and designed to represent the true geometry and performance characteristics of our rainscreen systems — giving you a clearer picture of how each panel interacts with the substructure, openings, and other building elements.

- Identify clash detection and design coordination

- Faster specification and approvals

- Alignment with our manufacturing workflows

Downloading Sotech’s BIM objects ensures maximum compatibility between your design and our manufacturing systems.

“If clients use our BIM components, we can extract the data we need to quote, model and plan production with incredible speed.”

Mo Jenaban, Technical Lead at Sotech

FEM (Finite Element Method)

At Sotech we use Finite Element Method (FEM) simulations as a critical part of our design validation process.

FEM allows us to digitally test how a facade system will perform under real-world conditions before we begin fabrication. Using advanced simulation software, our technical team can analyse how panels will respond to external forces such as

- Wind load pressures

- Deadloads and structural movement

- Thermal expansion and contraction

- Fixing configurations and performance

- Panel material, thickness and geometry variations

Mo Jenaban, Technical Lead at Sotech, explains Sotech’s approach to Finite Element Analysis:

“FEM gives us the ability to validate panel performance in a virtual environment. It’s a powerful tool in the design phase – ensuring the system can withstand wind pressures, thermal effects, and other real-life stresses long before we cut the first panel.”

Mo Jenaban, Technical Lead at Sotech

Virtual Reality (VR) Experience

Sotech’s virtual showroom lets clients explore panel assemblies, fixings, finishes and layout options in immersive 3D. This is especially powerful in early design stages when reviewing build-ups, solving interface challenges, or comparing material choices.

The virtual experience allows clients to:

- Explore panel details from every angle, zoom in to inspect fixing methods, and evaluate surface finishes in real-time.

- Validate design intent by visualising how panels will interact with elements such as windows and subframes.

- Experiment with materials and finishes, switching between options effortlessly to determine the best aesthetic and performance.

“VR brings projects to life in a way that traditional modelling simply can’t.”

Mo Jenaban, Technical Lead at Sotech

Working with Sotech:

If you’ve got a project coming up – standard or bespoke – reach out to an expert member of our team today.

Sotech is recognised as one of the UK’s leading manufacturers of rainscreen cladding systems, and the earlier we’re involved in your project, the bigger the impact we can have.

By engaging us at concept stage, you gain direct access to our technical expertise, proven systems, and in-house manufacturing capability. This early collaboration means risks are spotted before they become problems, layouts can be refined, and specifications kept accurate – saving time and cost later on.

To see the difference first-hand, arrange a visit to our factory, where ideas are turned into fully engineered cladding solutions.

Call our technical team on +44 (0) 191 587 9213

Email us at technical@sotech-optima.co.uk

No downloads in list yet.

No downloads in list yet.