In today’s Sotechnical Insights, we’re breaking down CWCT testing to help you understand what exactly is tested and why this testing helps us to improve the quality of rainscreen cladding on buildings, making them safer for end users, with a longer lifespan for our customers.

What is the CWCT?

The Centre for Window and Cladding Technology (The CWCT) is an independent provider of guidance and information for building envelopes. CWCT provide the technical guidance for what should be tested and met from a façade point of view.

Made up of a committee of people across several disciplines including engineering, architects, and consultants, the CWCT is now able to cover a broad range of specialisms in the industry. As a result, the CWCT provides industry leading knowledge which is put into standardised documents for the industry to use.

Why do we complete CWCT testing?

Testing your rainscreen cladding build up using the CWCT testing standards provides excellent guidance on how rainscreen cladding panels perform in certain ‘weather’ conditions.

Through the CWCT testing process, we’re able to test for extreme weather conditions such as air infiltration, water penetration, wind loads and impact testing.

CWCT testing is broken into numerous modules and the guidance is spilt into two key parts:

- How systems perform from a physical point of view.

- Maintenance and servicing of panel systems from the client point of view.

Over time, CWCT testing has led to significant time and cost savings in construction for our customers. For example, using the results of our CWCT testing, Sotech has put a significant focus on engineering panels which includes a hook on system that enables fast and easy mounting and dismounting.

This means that any damaged panels can be removed and replaced with ease and in isolation. Of course, this makes the installation of our panels quicker and easier on site when the building is first constructed too, saving time and money in the overall construction project.

How does CWCT testing impact the rainscreen cladding sector?

The standards produced by The CWCT are not law, but they are the market independent standard for rainscreen panel design and performance. There is a huge drive to safety in the industry and it is a pretty common expectation in today’s market that panels would have both fire testing certificates and CWCT certificates.

The CWCT is able to provide independent testing in the industry, and an unbiased approach to paperwork and accreditations.

Designers and architects have been working with the CWCT standards for decades. In recent years other bodies, such as insurance companies, have taken an active interest in CWCT testing certifications.

National Building Specification (NBS) and National House Building Council (NHBC) standards are also now based on the CWCT ‘Standard for Systemised Building Envelopes’.

What is tested in a CWCT test?

In CWCT testing, there are two standards relating to building façade. Sequence A and Sequence B. Sotech works largely with Sequence B when performing tests.

Sequence B testing covers air permeability, water penetration, wind resistance (serviceability & safety) and impact resistance (soft and hard body).

In Sotech CWCT test reports, you would typically read a line like: “Rainscreen test derived of a Sequence B Standard”.

The CWCT has developed a whole performance standard for weather tightness in building envelopes.

CWCT testing covers:

- Wind resistance (serviceability);

- Wind resistance (safety);

- Watertightness (dynamic and static); and,

- Impact resistance. (hard and soft body)

The results from a CWCT test are then applied to the system, material and finish tested. In our testing, we tend to use the lowest alloy aluminium possible so that any improvements to the material can carry the same test certificate.

It is worth noting that bespoke testing is highly appropriate for certain exposed or elevated buildings or buildings with completely custom made rainscreen systems.

For example, Sotech worked with M. Clarke to test the Bespoke Extrusion for student accommodation Bath Court in Birmingham.

Sotech designed four new dies for the development of the system along with project specific CWCT testing at Vinci Technology Centre.

The CWCT has also produced an excellent guidance document summarising a lot of key principles in CWCT testing standards, along with guidance for built up walls.

The document:

- Includes guidance for cavity widths and joint types;

- explains why we need the air gap;

- explains the difference between drained and ventilated systems; and,

- demonstrates how to design a better system in relation to equal pressure.

More specifically, what happens in a CWCT test?

Testing is carried out in the order listed below.

Wind resistance (Serviceability & Safety):

For the CWCT test, a test rig is created, made up of a clad wall within a sealed chamber. During the test, air is then pump in and sucked out of the chamber to give you dynamic pressure.

Negative pressure pushes the panel faces out, like a balloon. Positive pressure pulls in the panels, mimicking the effect of load onto the wall.Before the test, all gaps and modules are taped up and sealed up to create an airtight wall. Any gaps that open up during the test demonstrates where faults are in the system.

Wind resistance is tested to 2400 pascals then up to 3600 pascals (Safety). Pressure is applied to stress all elements of the rainscreen system including panels, rails, hooks brackets and fixings.

Watertightness (dynamic pressure):

An aeroplane engine (aero-engine) is then used to blast 600 pascals of water into the panel, mimicking hurricane rain and wind. The aim of this test is to try and force water into the panels.

This is why Sotech always utilise labyrinth joint systems. With labyrinth joint systems, water has to ‘come in, up and over the joints’, which is almost impossible to do.

Impact resistance:

Soft and hard body impact testing is carried out.

For the hard body test, a solid steel ball is swung at the wall to test point load impact.

In the soft body testing, a series of impacts using a leather bag of glass spheres (50kg) are swung into the façade from different distances.

The build up is tested on each element and a ‘pass’ or ‘fail’ is recorded in the Test Report, based on the performance of the system as per the guidance set out in by the CWCT.

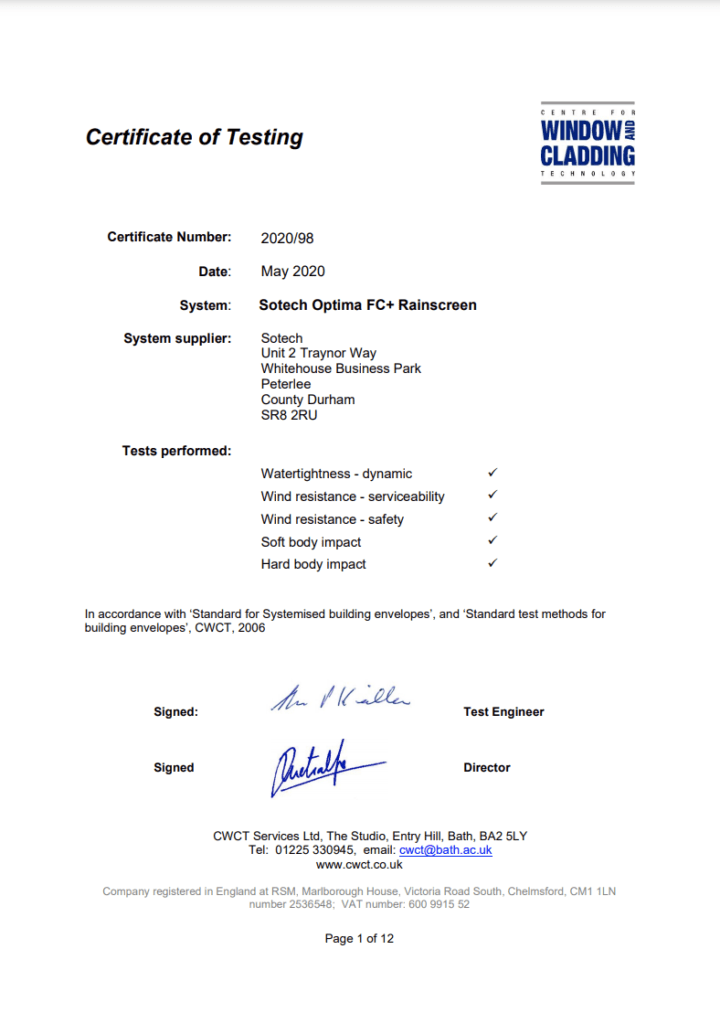

If the panel passes the test, a Test Certificate is issued.

CWCT testing on the Sotech range of rainscreen cladding systems

Sotech’s Optima suite of rainscreen façade systems have been successfully tested in line with CWCT Standards. This covers Air permeability, Water Penetration, Wind Resistance (Serviceability & Safety) and soft & hard body impact testing.

Click here to review the CWCT test certificates available for the Sotech Optima suit of systems.

No downloads in list yet.

No downloads in list yet.