Specifying Anodised aluminium in the rainscreen sector: the environmentally responsible choice?

A special thanks to Andrew Robinson at United Anodisers and Remco Baartmans at Alumet for contributing to this expert article.

As building designs become more dynamic, architects are looking for modern materials that allow them to put their original design flare on a building, with an environmentally friendly material choice. Using Anodised Aluminium in the final rainscreen build up, with its exceptional repeated recyclability, minimum maintenance and proven lifetime performance, is the perfect solution for architects who have originality and the environment paired in their sights.

Why is anodising so environmentally friendly?

The anodising process does not produce CO2 or Solvent emissions and does not require any environmentally sensitive pre-treatment like chromatins as an example. For this reason, architectural anodising plants are capable of responding to the most stringent environmental standards and aluminium is often called the green metal.

One of the key advantages of Aluminium over other materials is that it can be recycled repeatedly through simple re-smelting with minimum loss on each cycle. This means in practice that the entire panel can be broken down and recycled.

Anodised Aluminium can be recycled directly without the removal of any surface coatings that for other treatments may contain traces of chromate or other onerous substances. Nothing in the anodising or colouring process contains any volatile organic, toxic, or substances that have an environmental impact.

More than 30% of Aluminium consumption is satisfied with recycled Aluminium and over 90% of the Aluminium used in buildings is recycled at the end of the building’s life. The recycling process requires only 5% of the energy required for production of primary Aluminium.

This has been proven to be a significant contribution to environmental sustainability and thus minimising the ongoing effects to the planet.

What are the benefits of using an anodised finish in rainscreen cladding?

Anodising enhances the natural qualities of Aluminium still further. It permits a strong contemporary finish with incomparable corrosion and abrasion resistance. Unique amongst surface treatment, it is not simply a film applied to cover the surface – it is totally integrated with the metallic substrate.

A totally homogeneous appearance can be guaranteed, thanks to the nature of the anodising process. Colours textures and patterns can be combined with the anodic film enhancing the natural metallic appearance without affecting the total UV resistance and A1 fire rated properties of the finish. Anodised aluminium is also more immune to the effects of sun, sea and challenging locations and was in fact developed for commercial applications in the early 1930s and used to protect sea planes.

The living quality of the natural metallic sheen combining texture with colour, guarantees a creative interaction of the surface and shapes of the building. This can be seen on the award winning CTAR Leeds Becket University project.

The benefits of anodising include:

No Filiform corrosion

Filiform corrosion is an attack on the hidden inter-layer between the aluminium and the surface coating which results in the propagation of corrosion under the surface coating. Resulting from surface defects or scratches it cannot be easily remedied. With anodising the oxide (anodic) layer is integrated with the aluminium and as a result there can be no corrosion.

Abrasion Resistance

Aluminium Oxide is a very hard compound which is second only to diamond on the Mohs scale of mineral hardness. Anodised Aluminium surfaces offer superior scratch and abrasion resistance than other alternative finishes.

Beyond the recyclability and long-term strength and resistance of Anodised Aluminium, one of the most desirable benefits for architects is the long-term reliability of anodised rainscreen panels.

Aluminium that has not been oxidised is a relatively soft material when compared with steel or titanium. Aluminium Oxide, on the other hand, is an extremely hard material. In fact, Aluminium Oxide is often used in sandpapers because of its high hardness. When the anodising process forms an aluminium oxide layer on the outside of an aluminium alloy, it greatly increases its wear resistance because Aluminium Oxide is such a hard material.

Not only does anodising make the metal panels in rainscreen cladding panels stronger, it provides a layer of protection that can withstand the most direct sunlight and lashing of salty sea water at coastal locations. It is why we often see ship hulls, dock components, and oil rig structures built from Anodised Aluminium.

Selecting Anodised Aluminium panels for high elevations with direct sunlight, or coastal locations in the path of saltier water fronts can help to maintain a much longer lifecycle for the panels.

The strength of the panels, along with their durability in tougher climates has a positive impact on warranty. Under most warranties for Anodised Aluminium panels, less cleaning and upkeep is required to maintain the warranty, when compared with painted solutions, which often require panels to be cleaned every three months.

Anodised Aluminium has an A1 Fire Rating

The Euroclass A1 fire rating is considered one of the strictest fire protection standards for building materials in the world. Anodised Aluminium is A1 fire rated, meaning it is non-combustible and does not contribute to fire in any way. It can therefore be used as an exterior or interior cladding and roof coverings in both new buildings and re-clad applications wherever a non-combustible material is required

Beautiful Designs and Finishes

Finally, Anodised Aluminium is extremely easy to work with and can be specified in range of colours and shapes, with a range of patterns and designs available too.

Perhaps the best way to demonstrate this is through case studies where Anodised Aluminium was used extensively.

ANODISED ALUMINIUM IN USE: DESIGN PORTFOLIO:

CTAR Leeds Beckett

This award-winning project includes concave panels in PPC Aluminium, along with several design features, such as the 60m indoor running track viewing box, encased in red anodised Optima FC panels. The anodised red on red etched panels create contrasting tones to replicate muscle fibres under the microscope.

Birmingham University

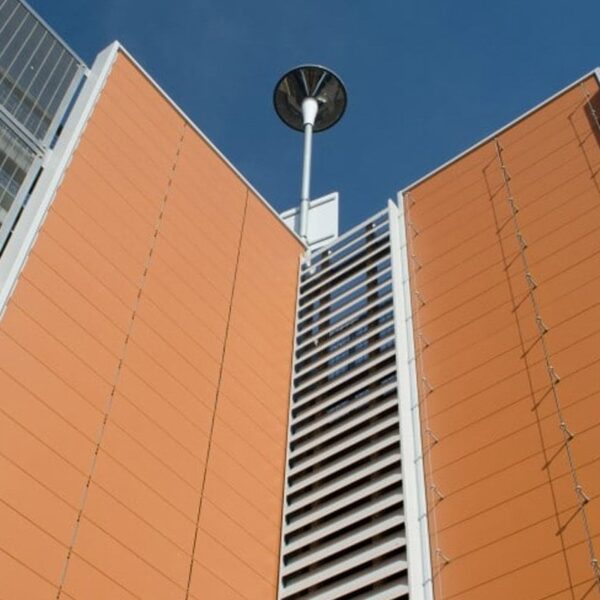

1400 sqm of the unique Sotech Optima Shingle System was used on the Collaborative Teaching Laboratory, Birmingham University. The shingles – in Anodised Regency Gold 2, 2.5 & 3 – were selected to create a scaled texture, which can be seen in the project photography. Due to a requirement to ventilate the high-level plantroom, the shingles in this area were perforated and fixed to a bespoke support grid, which integrates seamlessly with the surrounding cladding.

KELATY HOUSE

Over 9,500m2 of the brand new Optima FC+ Anodised Aluminium was been used in the ambitious completion of Kelaty House, a towering student accommodation and hotel in Wembley London. With three different surface finishes – matt, gloss and perforated – this stunning project demonstrates the range possible in anodised aluminium. In particular, it’s worth noting the captivating tree designs visible on the finished project, created by specially perforated panels. Anodising is perfect for perforations as it completely covers the edge of the holes along with the panel face.

GREENWICH ENERGY TOWER

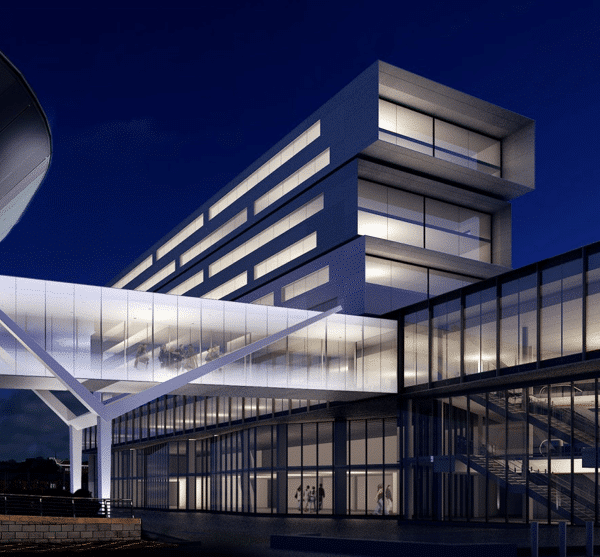

Fusing art with architecture, the Greenwich Peninsula Energy Centre is formed from perforated 4mm J57s anodised natural silver. Influenced by the ‘dazzle’ camouflage of the First World War and ideas from Cubist and Futurist paintings, the mesmorising design was created using an aluminium sub-frame which supports triangular anodised rainscreen panels manufactured by Sotech. Each panel was perforated and folded at different angles to create complex geometric patterns that filter natural light in the day and integrated lighting at night to create different visual effects. The materials and finishes were selected to fit the local environment – outlined by 1.6 miles of seawater – and meet a wind load performance requirement.

Specifying Anodised Aluminium in Rainscreen Cladding Build Ups

Anodised Aluminium is an outstanding choice for rainscreen cladding panels due to its durability, it’s flexibility and its long-term recyclability.

To discuss the use of Anodised Aluminium in your next rainscreen cladding project, please click here to speak to an expert.

No downloads in list yet.

No downloads in list yet.