Rainscreen façade design is an ever-evolving field, continually adapting to technological advancements, sustainability imperatives, and shifting architectural preferences.

In recent years, three key innovative trends have emerged in rainscreen cladding, reshaping the way cladding is considered, whilst transforming the built environment.

Here are three intriguing new trends in rainscreen façade design:

1. Biophilic Design Integration

Biophilic design incorporates natural elements and patterns to connect occupants with nature and has gained prominence in architectural planning in recent years.

In rainscreen façade design in particular, this looks like the integration of green spaces, natural materials and even living walls to create visually stunning and environmentally responsive façades.

One compelling example of biophilic design in rainscreen façades is the incorporation of vertical gardens or green walls. These living systems not only enhance the aesthetic appeal of the building but also contribute to air quality improvement, thermal regulation, and biodiversity conservation. By introducing vegetation into urban environments, architects can mitigate the urban heat island effect, reduce energy consumption, and create healthier indoor environments.

In a pioneering new collaboration, Sotech has recently partnered with leading urban biodiversity company Vertical Meadow to introduce an innovative ‘living wall’ rainscreen cladding solution designed to enhance urban environments and bring back wildlife to our densely populated cities.

Adapting Sotech’s renowned Optima FC+ system, the collaboration introduces a groundbreaking design featuring a hinged perforated front panel, facilitating the seamless insertion of a seed membrane. The product is delivered dry to site by Sotech and integrated with irrigation systems, Wi-Fi, power, and water supplies, and activated to initiate the controlled germination process overseen by Vertical Meadow.

As the plants flourish and bloom over time, progress is conveniently tracked through user-friendly inspection and maintenance apps. This pioneering approach stands out as seeds are nurtured directly in place, resulting in a more cost-effective, lightweight, and sustainable system. With simplified maintenance and logistics, there’s no need to transport live plants to the site, making it a game-changer in greener construction practices.

Learn more about Optima Meadow >>

2. Dynamic FaCades with Responsive Technologies

Advancements in building technologies and materials have enabled the development of dynamic façades that adapt to changing environmental conditions, user preferences, and energy demands. These responsive façades incorporate innovative systems such as kinetic elements, adaptive shading devices, and smart glazing technologies to optimise performance and user comfort.

One notable trend in dynamic rainscreen façade design is the integration of kinetic elements that respond to environmental stimuli such as sunlight, wind, or temperature. These kinetic façades can dynamically adjust their configuration, orientation, or permeability to optimize daylighting, ventilation, and solar control, thereby enhancing energy efficiency and occupant comfort.

Similarly, the use of adaptive shading devices, such as automated louvers, fins, or blinds, allows architects to regulate solar heat gain and glare while maintaining access to natural light. These responsive shading systems can adjust their position, angle, or opacity in real-time based on climatic conditions, building orientation, and user preferences, improving thermal comfort and reducing energy consumption.

As an example of architectural fins in use, Optima FC was chosen for The Core, Science Central project. The features of the building include horizontal and vertical fins projecting out from the panel joints.

The features of the building include horizontal and vertical fins spanning out from each floor, created so that the gold anodised fins on the mid points of the panels hang over the floor below to create a picture frame effect.

In this example, the expert team at Sotech worked closely with Faulkner Brown Architects and installers Charles Henshaw to produce the unique panels for the project, which has so far won awards such as the CEEQUAL ‘Excellent’ award, for being an incredible example of sustainable building, and the Legacy Sustainability award.

The installation of fins can be incorporated on site or fitted to the panels in the factory.

3. Digital Fabrication and Parametric Design

The growth of digital fabrication technologies and parametric design tools has revolutionised the way rainscreen façades are conceived, fabricated, and assembled. These advanced techniques enable architects to create highly complex and customised façade geometries, optimise material efficiency, and streamline construction processes.

Innovative approaches such as algorithmic design, generative modelling, and 3D printing allow architects to explore novel forms, patterns, and textures in rainscreen façade design.

By harnessing computational algorithms, designers can generate intricate façade patterns that respond to site-specific conditions and environmental parameters.

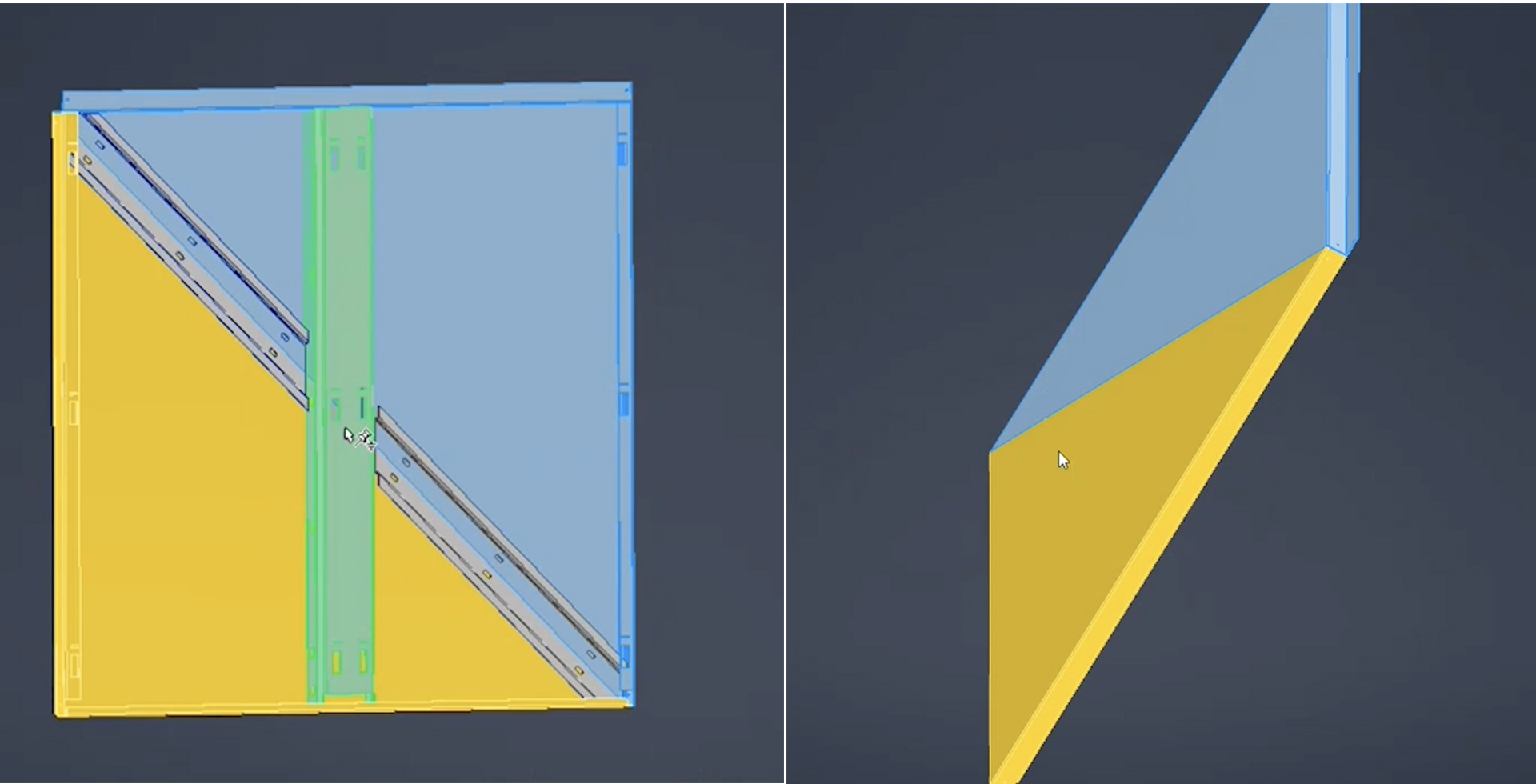

In Discovery Quay in Salford, for example, the expert team at Sotech worked closely with Britplas Facades and their team of specialists to design a truly unique ‘basket weave’ façade. The Sotech team used enhanced 3D modelling to develop a method to secret fix the triangular sections onto standard panels at the Sotech fabrication facility, to reduce the quantity of parts the installer would have to handle.

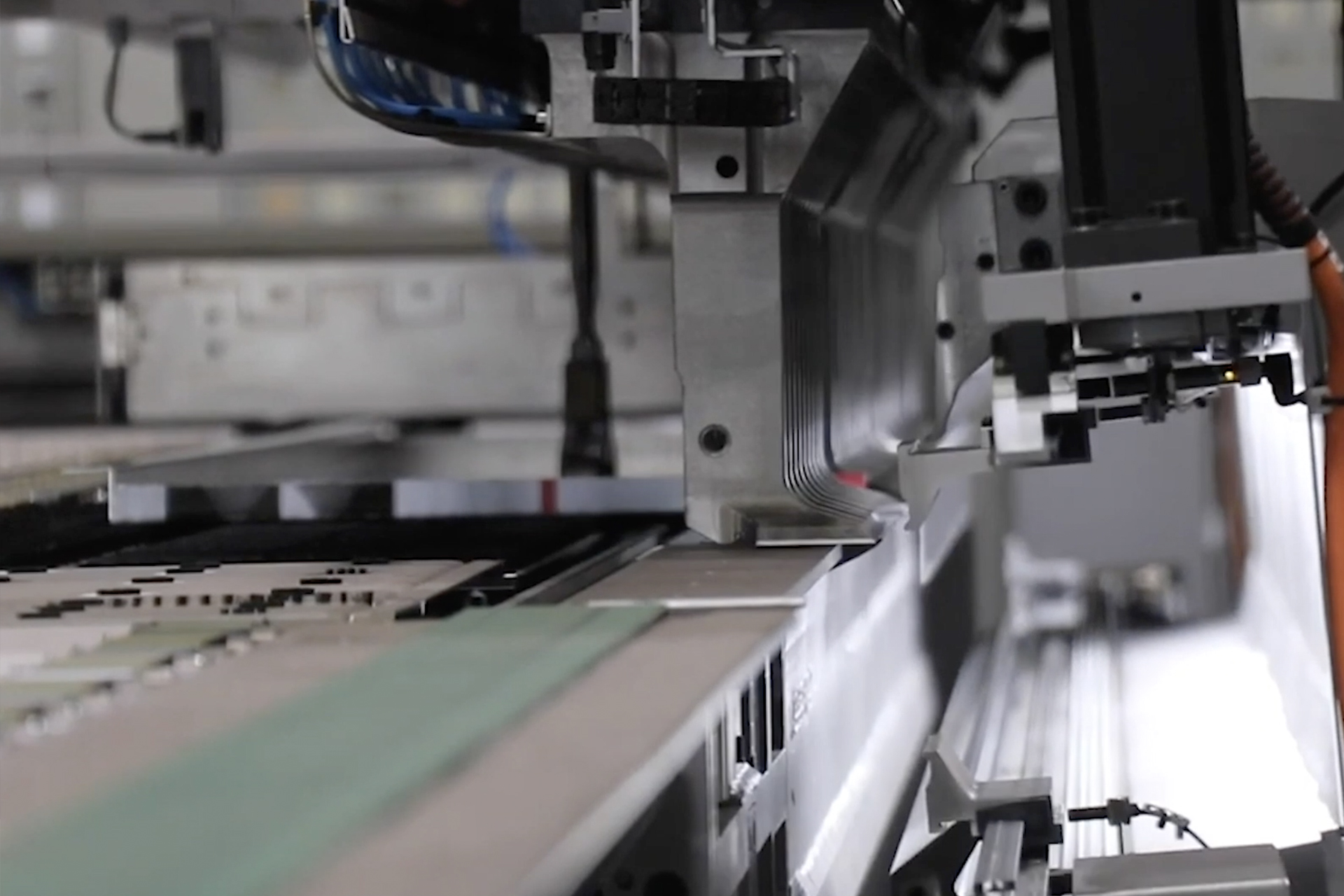

Beyond powerful design tools, digital fabrication technologies such as CNC milling, laser cutting, and robotic manufacturing enable the precise fabrication of façade components with minimal waste and maximum efficiency.

Sotech’s manufacturing facilities incorporate some of the very latest and most technologically advanced machinery, including a number of CNC pressbrakes (folding millimetre perfect parts up to 6M long, which is larger than the current industry standard), a rapid automated punching machine (producing bespoke shapes and perforated blanks to a high tolerance), a 12M CNC router (cutting composite, solid material blanks and intricate shapes with a smooth finish), along with a fully automated production line that turns flat metal sheets into finished panels in seconds.

Prefabrication and modular construction techniques further speed up the assembly process, reducing construction time and costs while ensuring quality control and consistency.

In conclusion, these three trends—biophilic design integration, dynamic façades with responsive technologies, and digital fabrication —are reshaping the future of rainscreen façade design, pushing the boundaries of innovation, sustainability, and aesthetics. By embracing these trends, architects and designers can create resilient, adaptable, and visually captivating façades that enhance the built environment and enrich the human experience.

Useful links:

Contact our expert team for a conversation about your next project >>

Full Optima range of rainscreen façade systems and materials >>

Inspiring range of case studies to inspire your next project >>

No downloads in list yet.

No downloads in list yet.