OPTIMA XPC RAINSCREEN

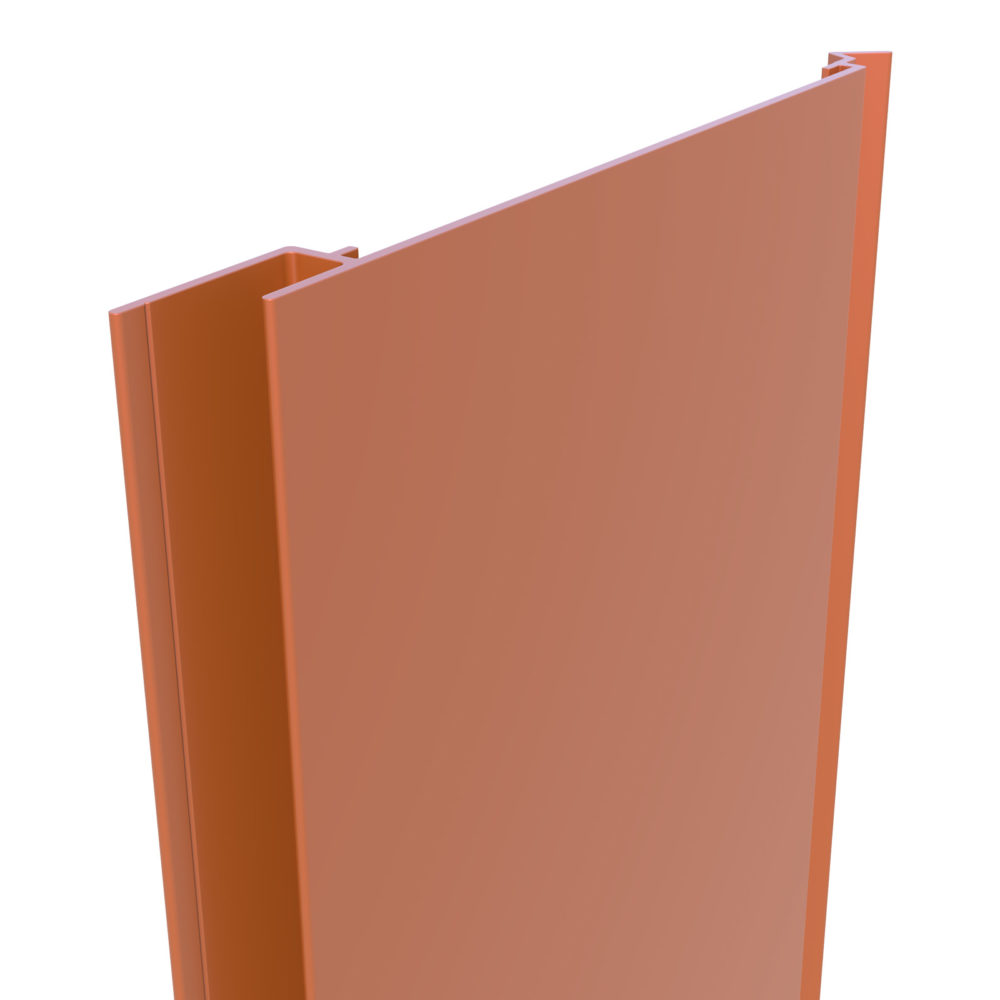

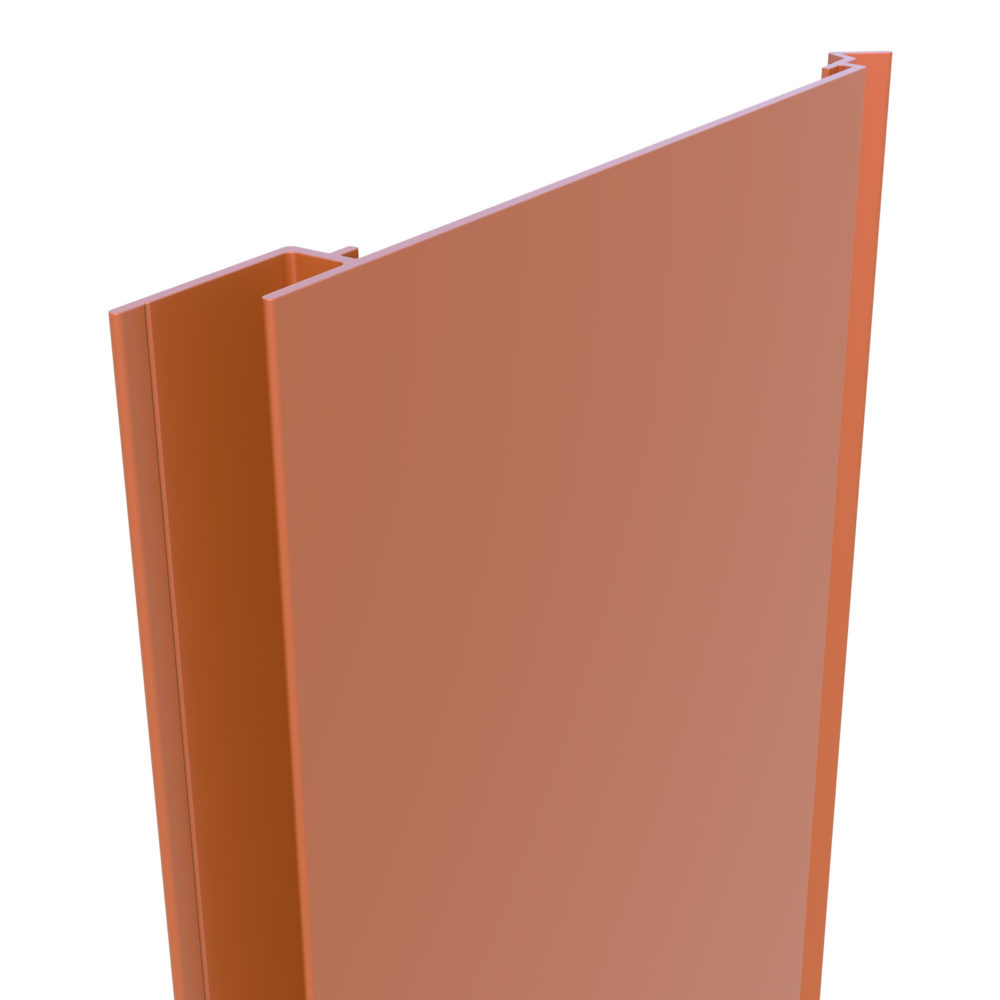

OPTIMA XPC IS AN ALUMINIUM EXTRUSION PLANK RAINSCREEN SYSTEM

Optima XPC Secret Fix Hook-On Rainscreen offers adaptable solutions from diverse material requirements through its versatile design, and accelerating project timelines with quick adjustments for streamlined construction.

Optima XPC features set flat face modules of 150mm, 190mm, 200mm, 225mm, and 250mm as well as a 150mm module castellated extruded aluminium plank rainscreen. This development allows installers to securely lock hooks in position on-site, streamlining the installation process and drastically reduce lead times for all parties. Its versatility is such that a multitude of materials and thicknesses (from 2.0mm to 4mm) can be used on one universal carrier.

This product can be used as a weathered screen introducing ventilation at the base of a wall and at the top. Some ventilation can be introduced at the cross-plank joints by leaving a gap with the support structure behind creating a baffle.

BENEFITS OF THE OPTIMA XPC SYSTEM

The Optima XPC Rainscreen system offers a superior approach to traditional cladding with a range of benefits that enhance the functionality and aesthetic of your building. Whether for new construction or a refurbishment, the Optima XPC rainscreen system is a low maintenance choice, delivering robust long lasting value and excellence.

- Due to the inherent strength of an aluminium extrusion, this product only needs to be 15mm thick, which makes it ideal for refurbishments where space is limited due to adjacent boundary restrictions.

- All planks can interlock with each other. Optima XPC lends itself to use in all areas – including low-level vulnerable areas through superior deflection and impact resistance.

- All commercial finishes may be incorporated on one elevation to create an almost limitless effect of colours and shapes.

- Full range of Euroclass A1 and A2 – s1,d0 panel materials from 2mm – 4mm.

- Mechanical fixing methods and no use of adhesives, providing true A1 and A2 cladding systems.

- The XPC is secretly fixed onto an extruded aluminium support framework horizontally, vertically or diagonally.

- The aluminium planks are connected by a simple interlocking male/female joint, which offers either a recessed or hairline appearance.

- The system has been independently tested and certified to meet CWCT rigorous specification for rainscreen cladding.

- NBS specifications available tailored to your project.

- Drained and ventilated system creates a weather shield in front of a primary structure.

- Economical: Optima XPC is the economical version of the Optima XTR Rainscreen System, offering a light-weight, cost-effective solution.

GET IN TOUCH TO ARRANGE A CPD

OPTIMA XPC PANEL VARIETIES AND SIZES

Versatile Sizes and Materials for Every Architectural Need

Optima XPC Panels offer a versatile and high-quality solution for modern architectural needs, available in various sizes and finishes to accommodate different design aesthetics and performance requirements. With materials ranging from 1.5mm to 4mm and available in Anodised Aluminum, PPC Aluminum, Pre-Paint, A1 & A2 ACM, Copper and Zinc, these panels are designed to meet a variety of architectural demands. Sotech’s state of the art machinery allows flexibility in precision manufacturing of panels upto 3800mm x 1300mm, providing ample coverage for large areas. The option for bespoke sizes ensures that even the most unique design visions can be brought to life. The different material options offer a balance between durability, aesthetic, and fire safety, making them a suitable choice for a wide array of construction needs.

Contact us for maximum and typical panels sizes available

DURABLE AND ADAPTIVE SUBSTRUCTURE

Building a Reliable Foundation with Quality Materials

The Optima XPC system isn’t just about the panels; the substructure is equally important in ensuring longevity and performance. Built using materials from quality brands, the system guarantees reliability and durability. The system’s adaptability is evident in its suitability for all types of wall constructions, whether for new builds or refurbishments. The fully adjustable system allows for precise alignment and levelling of the cladding zones, accommodating variations in insulation thickness and wall irregularities. This precision ensures a flawless finish and long-lasting performance, keeping the project’s aesthetic and structural integrity intact over time.

INSTALLATION AND VENTILATION SOLUTIONS

Ease and Versatility in Application

Finally, the Optima XPC system’s installation and backing walls are designed with ease and versatility in mind. Compatible with various types of external insulation and wall constructions, it offers solutions for easy installation. The system’s adjustability, along with the use of wafer head, self-tapping stainless-steel screws, ensures a secure and precise installation. Ventilation zones behind the panels are often designed to exceed CWCT minimum requirements, considering structural rails and other constraints. With such detailed attention to functionality, adaptability, and aesthetic, the Optima XPC system provides a comprehensive solution for modern cladding needs.

ANODISED ALUMINIUM

Anodising is an A1 non-combustible finish. It is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts.

Due to the nature of the anodising process and the tight quality controls on both the aluminium and the surface treatment, anodising has a homogeneous (matching & consistent) appearance.

Colours, textures and patterns can be incorporated in the anodic film, enhancing the natural metallic appearance without affecting the total UV resistance of the rainscreen cladding.

Anodising enhances the natural qualities of aluminium further; it permits a strongly contemporary finish with incomparable corrosion and abrasion resistance.

Aluminium is exceptionally recyclable, requires minimal maintenance and has proven lifetime performance.

Polyester Powder CoatED ALUMINIUM (PPC)

PPC is an A2 limited combustibility finish.

PPC is a type of dry coating, rather than a conventional liquid paint, and is applied to metal rainscreen as a free flowing, dry powder. The powder is applied to rainscreen panels electrostatically and is then cured under heat to allow it to form a ‘skin’. This electrostatic powder process means we can ensure complete coverage of the panels, even on more complex shapes.

Powder Coating can produce a much thicker coating than conventional liquid coating leaving PPC rainscreen cladding with a hard finish. This is much tougher than normal paint and its strong abrasion and corrosion resistance properties make it extremely durable and long lasting.

If you are looking for a finish to make your project stand out PPC is a great specification choice with a range of 200 standard RAL colours and a wide choice of special effects offer a great alternative to anodised aluminium and stone, natural effects and different textures can be used to add a unique touch to your project.

OPTIMA XPC CWCT TESTING

The CWCT ‘Standard for systemised building envelopes’ gives a framework for specifying building envelopes and provides a ‘Specifiers checklist’ showing information that will change from project to project.

This includes:

- Internal and external environment

- Air permeability

- Thermal performance

- Access and safety

- Design life

Tests performed:

Watertightness – dynamic

Wind resistance – serviceability

Wind resistance – safety

Soft body Impact

SOTECH Optima XPC

Certificate Number: 2010/42

Fire Test Performed at: Vinci Technology

Date test performed: July 2009

The Spark

Outwood Academy

Asda Multi Storey Car Park

OPTIMA XPC DOWNLOADS

PLEASE ADD WHAT YOU REQUIRE TO YOUR DOWNLOAD LIST.

Once you have added all the files you require to your download list you can gain access to them using the downloads button in the top right or bottom right of your screen. If you have any issues, comments or questions please get in touch and an expert will be in touch as soon as possible.

SOTECHVR

A NEW WAY TO VIEW OPTIMA SYSTEMS

No VR headset? No problem! SOTECHVR will automatically start a standard 3D version if no headset is detected.

For a fully immersive virtual reality experience, SOTECHVR allows users to examine complete 3D models of our Optima range, change the rainscreen system to a material/finish of your choice, learn more about fire safety and rainscreen testing.

No downloads in list yet.

No downloads in list yet.