When it comes to specifying and installing rainscreen cladding for buildings in the UK, fire safety is not just a consideration – it’s a non-negotiable. In the wake of updated regulations, specifiers must ensure that every rainscreen façade system demonstrates compliance with stringent fire performance standards, particularly for high-rise and high-risk buildings.

At Sotech, safety is at the heart of everything we do. With over 40 years of experience in façade cladding and a rigorous fire testing process, we’re here to guide you through what you need to know about fire safety in rainscreen cladding – and how our Optima rainscreen systems are designed to meet the highest standards.

What Fire Tests Must Rainscreen Cladding Systems Pass?

Euroclass testing:

All materials used in rainscreen cladding must be classified to Euroclass standards (EN 13501-1), which measure reaction to fire performance. For high-rise and high-risk buildings, UK Building Regulations only permit Euroclass A1 (non-combustible) or A2-s1,d0 (limited combustibility) materials.

BS8414-2: Large-Scale Fire Testing

For certain applications, cladding systems may also need to demonstrate compliance through large-scale fire testing. In the UK, BS8414-2:2015 is the recognised large-scale test method for assessing the fire performance of non-load bearing external cladding systems fixed to and supported by a structural steel frame. This full-scale test replicates a realistic fire scenario, such as a blaze breaking out of a window in a high-rise building.

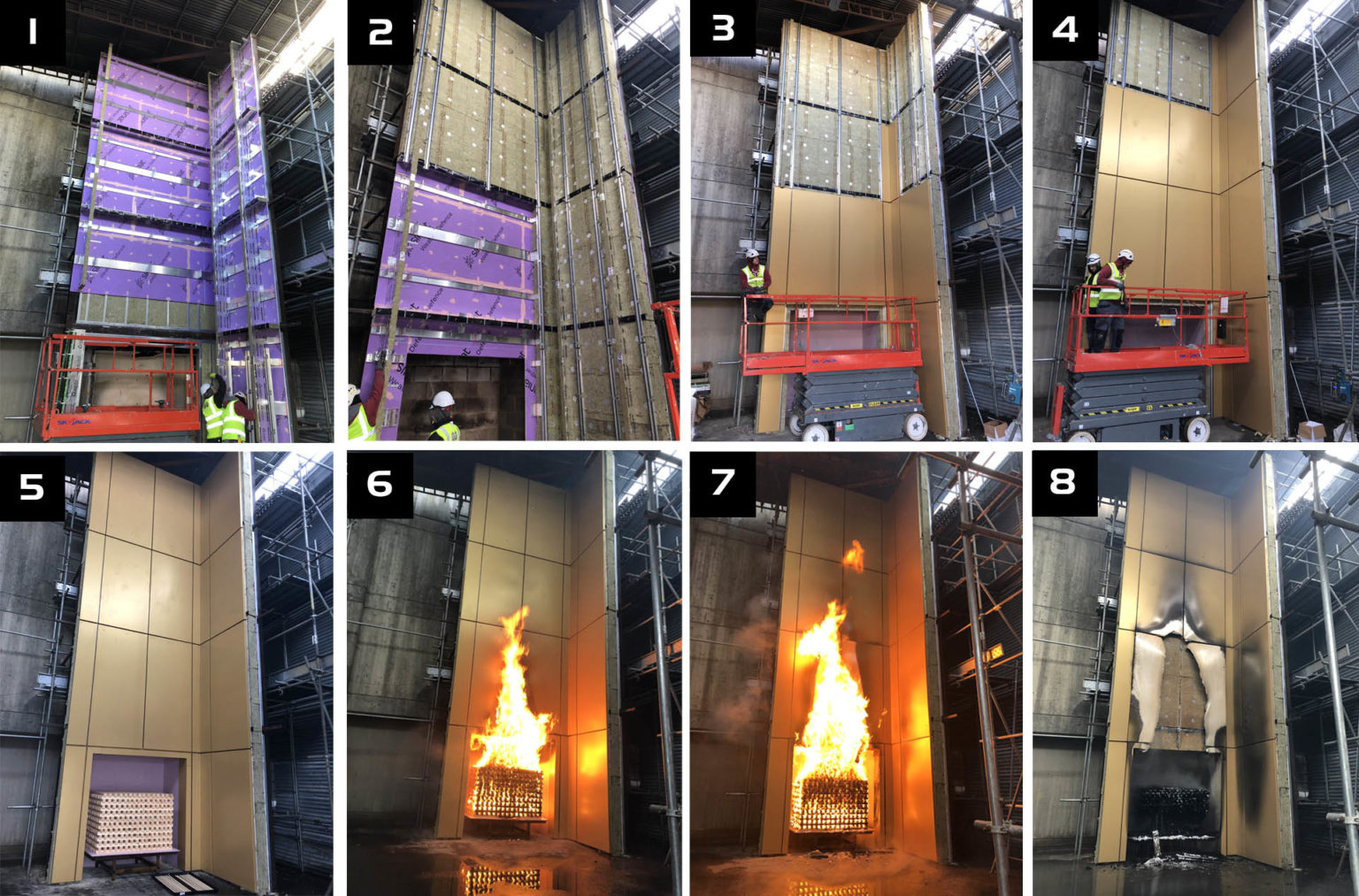

What happens in a full scale rainscreen cladding fire testing process?

Step 1 – Review:

The technical team at Sotech will review the specification document and advise the best possible build-up of individual parts and highlight potential risks, issues and opportunities.

Step 2 – Coordination:

The project manager responsible will organise a full scale test at one of the facilities around the world (including booking in the test, arranging shipment of all necessary materials and organising the required personnel for the test).

Step 3 – Testing:

The entire cladding system – including the carrier system, panel material, finishes, firebreaks, and fixings – is mounted to a 9-metre demonstration wall and exposed to real fire conditions.

Step 4 – Certification:

Once the test has been successfully completed a certificate will be presented to show that the build-up has passed the BS8414-2 fire safety test.

The BR135 Classification: Your Benchmark for Compliance

Passing BS8414-2 is only the first step. To be deemed suitable for use on high-rise buildings in the UK, the rainscreen system must also achieve BR135 classification. This confirms that the cladding build-up has met the performance criteria under test conditions – including flame spread, temperature limits, and system integrity.

True Euroclass A1 and A2-s1,d0 Materials – With No Adhesives

Sotech has a long history of testing, and was one of the very first UK cladding manufacturers to carry out large scale system tests in 2006/2007.

Setting a precedent for rigorous fire safety standards, long before regulations demanded it, Sotech now offers a full range of Euroclass A1 and A2-s1,d0 materials, including PPC aluminium, anodised aluminium, zinc, stainless steel, and more – each suitable for use in high-rise or sensitive applications. Importantly, installers are able to specify mechanical fixing methods for a true A1 fire safety rating.

CWCT Sequence B Testing – Validated by UL Solutions

Fire safety is only part of the story. For a facade to perform safely and reliably over time, it must also withstand real-world weathering. A number of Optima Rainscreen Systems have therefore been to CWCT Sequence B, with UKAS accreditation by UL Solutions. This comprehensive test sequence includes:

- Dynamic and static water penetration testing under simulated wind-driven rain and pressure

- Air leakage performance under varying pressures

- Impact resistance across both soft- and hard-body impact scenarios

- Cyclic wind load testing, covering both positive and negative pressures

Which Optima Systems Meet These Fire Safety Standards?

The following systems in the Optima range are tested to BS8414-2 and classified to BR135:

- Optima FC+: Secret-fix hook-on system with seamless finishes

- Optima TFC+: Cost-effective through-fix system with discreet fasteners

- Optima Edge: Minimalist, floating aesthetic with concealed fixing

Tested systems use mechanical fixings, are free from adhesives, and are available in A1 or A2-rated materials, offering total compliance and peace of mind.

The Safe Hands of the Industry

At Sotech, we pride ourselves on being “safe hands” in façade cladding – and we’re proud of our long testing history, and our commitment to fire safety first and foremost. From initial consultation through to final delivery, our team works closely with architects, main contractors and fire consultants to ensure full compliance with UK and international standards.

If you would like to discuss your next rainscreen project, or need advice on specification, fire safety or performance we’re here to help.

Speak to the Experts

technical@sotech-optima.co.uk

+44 (0)191 587 9213

www.sotech-optima.co.uk/contact

No downloads in list yet.

No downloads in list yet.