OPTIMA BRICKTECH SYSTEM

Discover the Optima BrickTech System, an innovative alternative to traditional brickwork and cladding systems.

This new solution seamlessly combines the classic aesthetics of real, natural bricks with the advanced performance of modern cladding technology. Engineered for durability and ease of installation, the Optima BrickTech System is designed to work with a range of brick types, redefining brickwork in contemporary architecture with a visually appealing facade and superior functionality.

BENEFITS OF THE OPTIMA BrickTech SYSTEM

The Optima BrickTech System offers a superior approach to traditional brick cladding with a range of benefits that enhance the functionality and aesthetic of your building. Designed for both performance and visual appeal, it's the ideal solution for new build and refurbishment projects.

- Independently Tested: Certified to CWCT Sequence B with UKAS accreditation by UL Solutions.

- Certified: NHBC approved method of certification.

- Drained & Ventilated: Features a ventilated cavity to create an effective weather barrier.

- Mechanical Fixing Methods: True A1; uses mechanical fixing methods exclusively to avoid adhesives.

- Configurable for Soffits & Headers: BrickTech profiles can be arranged to construct soffit & window head details.

- Simplified Corner & Column Details: The unique interlocking design of BrickTech profiles allows for easy construction of corner and column details, with pre-formed offsite corner details.

- F2 Frost Rated: Designed to withstand severe frost exposure, ensuring long-term durability in harsh weather conditions.

- Compatibility with Real Bricks: Designed specifically for natural, real clay bricks, accommodating various brick types and sizes.

- Adaptability to Shrinkage: The system accommodates shrinkage variations in bricks, ensuring consistent installation.

- Seamless Integration: Designed to integrate with other building façade elements.

- Fully Supported Subframe System: The system integrates with EVT brackets and offers a fully insured and approved subframe solution.

- Compliance with Industry Standards: Uses anodised aluminium profiles (6063T6),ensuring high-quality and certified materials.

- Specialised Profiles: Includes movement joint and soldier courses profiles for complex designs like vertical bonds.

- Efficient Corner and Column Detailing: Features interlocking design and pre-formed off-site corners for easy handling.

- System Guarantees: Available upon request.

- NBS Specifications: Available and can be tailored to your project needs.

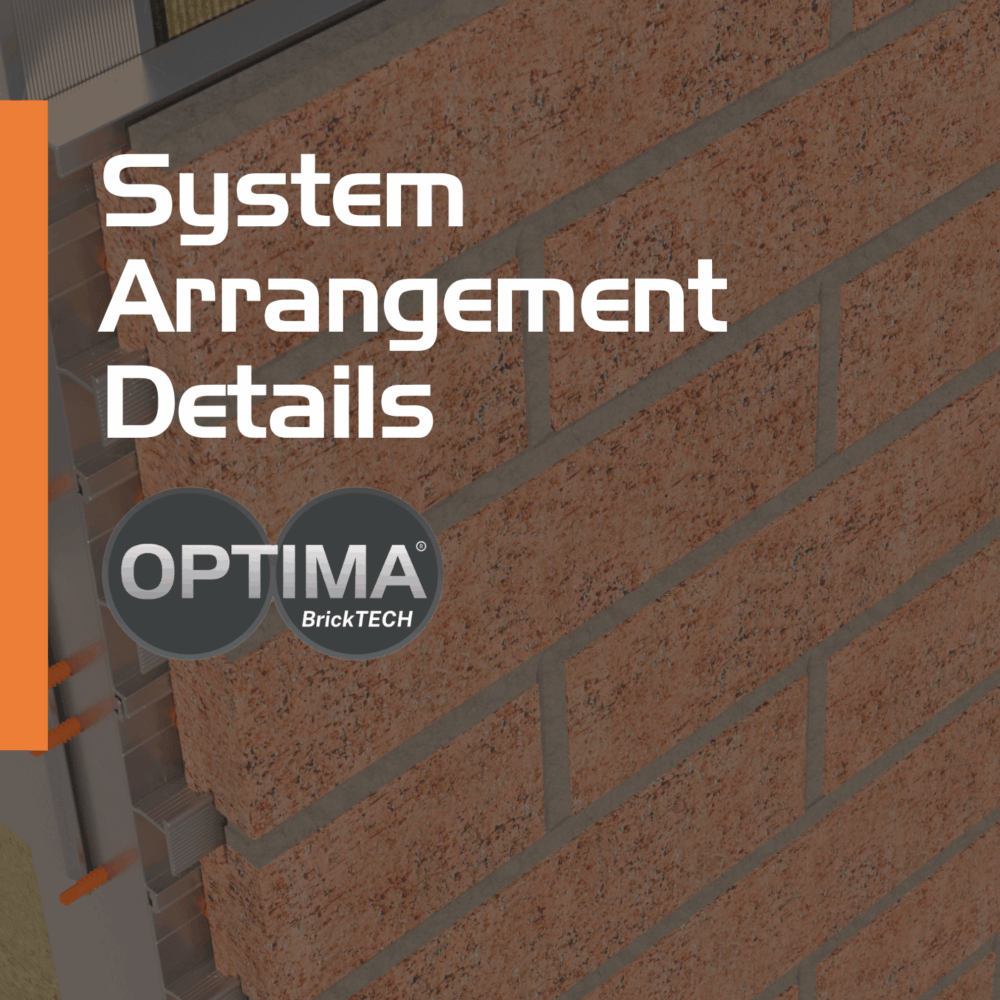

- Technical Arrangement Details: Available here.

- CAD Details: Are available, please contact our technical team 0191 5879213.

- Experience BrickTech: In our interactive VR here.

GET IN TOUCH TO ARRANGE A CPD

Designed for REAL Brick Applications

The BrickTech Brick Slip Cladding System

The BrickTech system provides mechanical support for real brick slips in either vertical or horizontal orientation using interlocking anodised aluminium profiles (6063T6). The system consists of three primary profiles, along with an upper movement joint profile for use with the movement joint brick slip, and a solider course span profile for vertical running bond designs.

Key Features:

- Real Brick Compatibility – Works with standard UK bricks (Ibstock FC: 63-65mm in height) and engineering bricks (64-67mm).

- Secure Interlocking System – Anodised aluminium profiles provide long-lasting stability and structural integrity.

- Precision Fit – Supports both standard (75mm courses) and engineered bricks, with an XL version available to accommodate size variations.

- Tested for Performance – Certified to CWCT Sequence B standards, ensuring strong brick-mortar bonding with a minimum 2mm kerf connection (typically 3mm).

- Versatile Design – Includes upper, middle, and lower profiles, as well as movement joint and soldier course span options for flexible layouts.

With its adaptable design and robust performance, BrickTech is the ideal brick-slip cladding solution for modern construction projects. Final specifications are tailored to each project’s unique brick selection.

INNOVATIVE BRICK SLIP SOLUTION

ENHANCING FACADE DESIGN WITH BRICKTECH

The BrickTech system collaborates with leading brick slip manufacturers to provide high quality, lightweight façade solutions. By leveraging cutting edge manufacturing technology, the system offers enhanced durability, flexibility and aesthetic appeal.

Key Features:

- Industry Leading Partnership – Working with top brick slip manufactures to ensure high quality innovation.

- Precision Corner & Column Solutions – Pre-formed off-site corner detailing ensures accuracy and efficiency

- Flexible Horizontal Design – Ideal for Soldier Course Stack Bond applications, enhancing architectural adaptability.

- Seamless Integration – Enables intricate detailing such as soffits and window heads for a cohesive design.

- Reliable Substructure Compatibility – Fits standard façade substructures using EVT brackets, ensuring a secure and approved subframe system.

- Engineered for Strength – Developed with RJ Facades, the brackets provide robust support for complex façade systems.

- Optimised for Performance & Aesthetics – Delivers precision-engineered solutions for complex cladding designs, ensuring durability, efficiency, and compliance.

- Lightweight & Versatile – Combines the durability of brick with reduced weight, making it ideal for high-rise, retrofit and low-rise applications.

- Fire & Weather Performance – A1 fire rated, F2 frost rated tested to CWCT sequence B, accredited by UL Solutions.

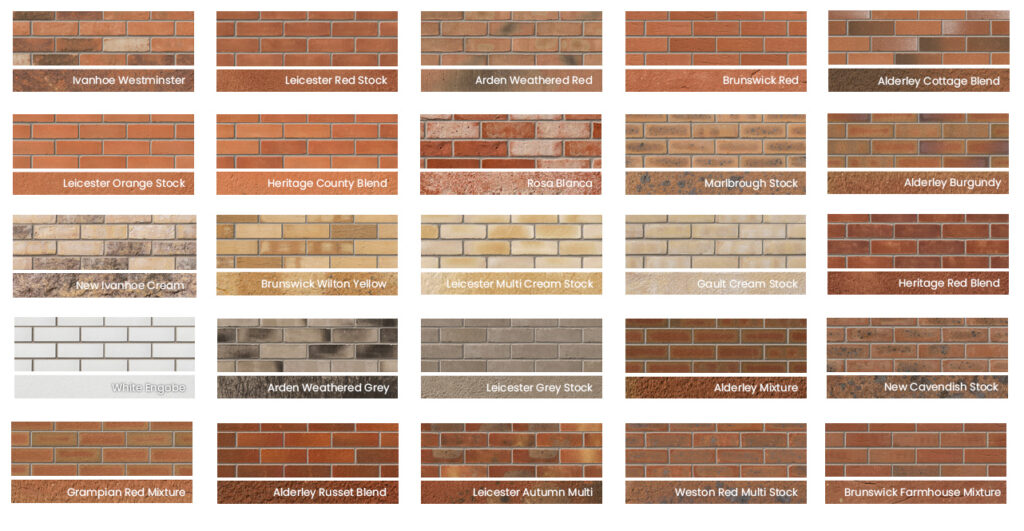

- Design Flexibility – Offers a wide range of colours, textures and sizes including bespoke options.

BrickTech Installation: Precision, Strength & Flexibility

The BrickTech system enables seamless installation with a durable, interlocking aluminium profile that securely supports real brick slips in both horizontal and vertical orientations. Designed for steel frames, concrete, masonry, and timber substructures, it ensures long-lasting protection and structural integrity.

Installation Benefits:

- Effortless Installation – Brick slips fit into a continuous, interlocking aluminium profile with horizontal and vertical reinforcement.

- Tested & Certified – Compliant with BS EN 755-9:2016 for safety and reliability.

- Versatile Design – Includes standard profiles plus specialized options:

- Movement Joint Upper Profile – Accommodates movement joint brick slips.

- Soldier Course Span Profile – Ideal for vertical running bond designs.

- Precision Corner Solutions – Preformed off-site corners simplify installation and ensure accurate alignment.

- Alternative Corner Construction – Corners can also be built with individual pieces connected to the subframe, tested to CWCT Sequence B standards (UL Report R4791092526 REV 1).

Built for Efficiency & Durability

The BrickTech system streamlines installation, enhances design flexibility, and ensures secure, long-lasting performance in modern facade construction.

OPTIMA BRICKTECH 3D MODEL

See our latest system in 3D

Interact with the Optima BRICKTECH 3D model. Zoom, rotate and truck forward using your mouse or fingers (on a touch screen). If you have any questions, please get in touch.

OPTIMA BrickTECH CWCT TESTING

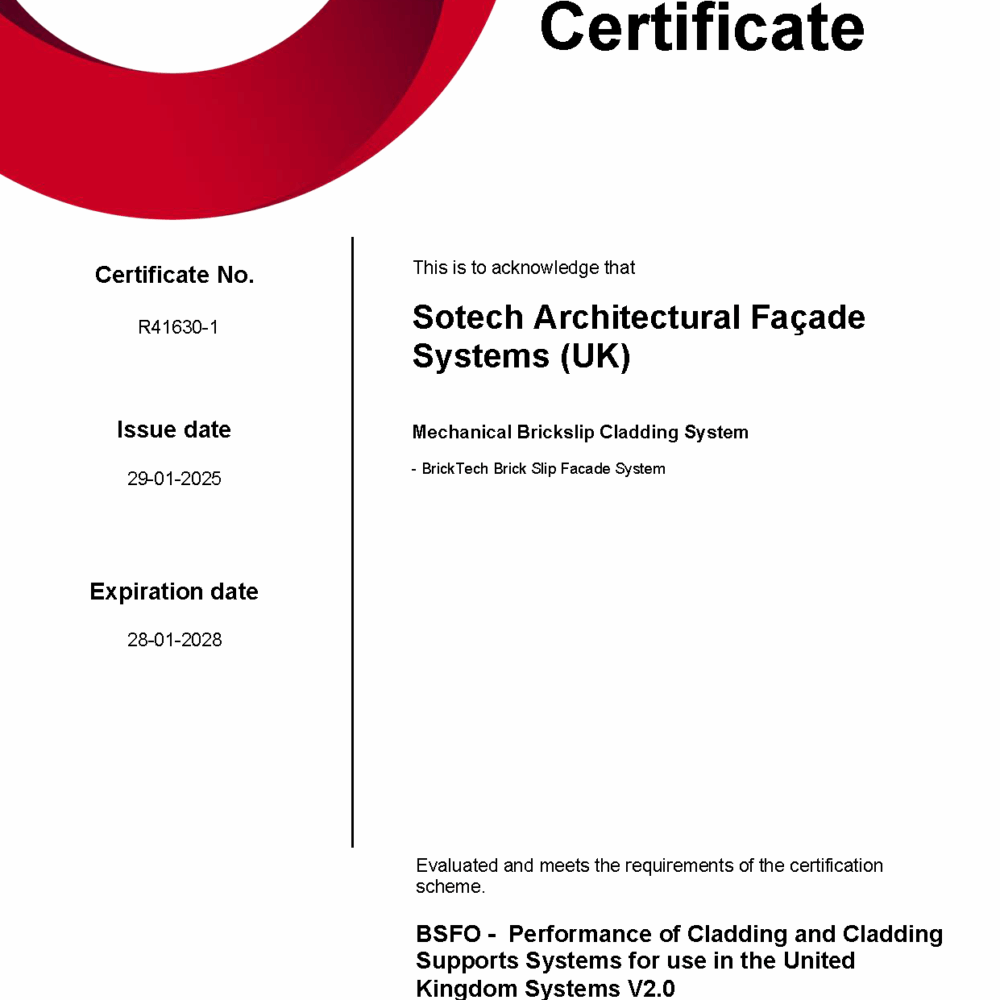

The certification assesses the performance of the façade/cladding system in accordance with CWCT Sequence B – Standard for Systemised Building Envelopes (2005). The evaluation includes the SFS support structure for through-wall applications.

This includes:

- Internal and external environment

- Air permeability

- Thermal performance

- Access and safety

- Design life

Tests performed:

Air leakage (infiltration and exfiltration)

Water penetration (static and dynamic)

Wind resistance (serviceability and safety)

Impact testing (retention of performance & safety to persons)

SOTECH Optima BRICKTECH

Certificate Number: R41630-1

Test Performed at: UL International (UK) Ltd

Date test performed: 29th January 2025

OPTIMA BRICKTECH DOWNLOADS

please add what you require to your download list.

Once you have added all the files you require to your download list you can gain access to them using the downloads button in the top right or bottom right of your screen. If you have any issues, comments or questions please get in touch and an expert will be in touch as soon as possible.

SOTECHVR

A NEW WAY TO VIEW OPTIMA SYSTEMS

No VR headset? No problem! SOTECHVR will automatically start a standard 3D version if no headset is detected.

For a fully immersive virtual reality experience, SOTECHVR allows users to examine complete 3D models of our Optima range, change the rainscreen system to a material/finish of your choice, learn more about fire safety and rainscreen testing.

No downloads in list yet.

No downloads in list yet.