A1 & A2 CLADDING – FIRE SAFE RAINSCREEN SYSTEM TESTED TO BS8414

SOTECH RAINSCREEN CLADDING SYSTEMS TESTED TO BS8414 STANDARDS

Sotech’s commitment to authentic engineering capability has been witnessed over several years in the testing and development of products. First successful fire test carried out in 2006 with Optima TFC applied to masonry wall and in 2008 Optima TFC fixed to and supported by a SFS wall. Both tests gained LPCB Red Book Entry.

In response to the British Standard (BS) technical specifications, Sotech has completed fire testing on various Optima Rainscreen systems at BRE, Watford, Element, Dubai and FPA, Gloucester.

The most recent tests to BS8414-2 were carried out on Sotech Optima Edge. (Refer to test reports below for specification requirements.)

What is BS8414-2?

BS 8414-2 refers to the fire performance of external cladding systems and is the test method for non-load bearing external cladding systems fixed to and supported by a structural steel frame.

The BS 8414 test methods were developed by the Building Research Establishment (BRE). They evaluate whether a cladding system subject to fire breaking out of an opening (such as a window) in an external wall, will result in excessive fire spread up the outside of the building and the potential for fire to re-enter at a higher level.

The tests are carried out in specialist laboratories, and are performed on full-scale systems (rather than small-scale samples) incorporating; joints and corner details, fixings, insulation, firebreaks, cavities and other elements of the system construction.

Our systems have been successfully tested to BS8414 and assessed against BR135, achieving classifications upto A2. BS9414 guidance allows us to extend our BS8414 test date to cover a wider range of compliant A1 build-ups.

FULL SCALE SYSTEM FIRE TESTING

Full scale fire testing is the most reliable way to prove a cladding system’s performance in real fire conditions. The test involves building a complete model of the proposed system – including the carrier, material, finish, and firebreaks – and mounting it onto a 9-metre demonstration wall.

The aim is to replicate what would happen if a severe fire broke out of a window in a block of flats or a storey in a high-rise building (above 18m). Unlike small-scale tests, this approach evaluates the entire cladding system working together, including:

- Cavity barriers and fire stopping

- The construction design

- The combined performance of the specified materials

This ensures the system is effective in slowing and controlling the spread of fire in tall buildings.

How does the Full Scale Fire Testing Process Work?

At Sotech, we guide you through a simple three-stage process to complete a BS 8414 full scale fire test.

Once the build-up passes the BS 8414 fire safety test, you’ll receive a certificate confirming compliance. This certificate can then be used to secure the necessary insurance for your project.

STAGE 1 – Specification review

Our technical team reviews your cladding specification in detail, advising on the best possible build-up and highlighting any potential risks or opportunities.

STAGE 2 – organising the fire test

We arrange the full scale test at an accredited facility, coordinating materials, shipment, and personnel. You’re welcome to attend the test days in person, or simply wait for the report.

STAGE 3 – Full scale fire test

The system is tested in line with BR 135 (Fire Performance of External Thermal Insulation for Walls of Multi-storey Buildings).

What is the Step by Step Full Scale Fire Testing Process?

1. Test Rig Preparation – Installation of substructure and framing

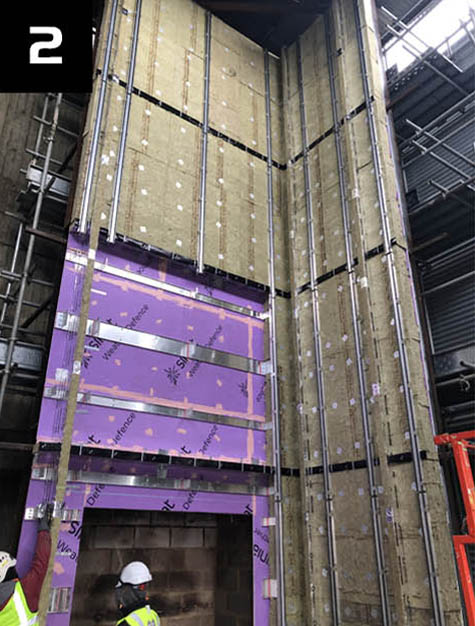

2. Insulation Installed – Fire-safe insulation and cavity barriers in place

3. Panel Installation (Lower Section) – Rainscreen panels fixed to the rig.

4. Panel Installation (Complete) – Full cladding system installed for testing

5. Ignition Source Ready – A fuel crib, constructed from moisture-controlled softwood battens arranged in an interlaced pattern, is prepared at the base of the rig

6. Fire Ignition – Fuel crib is ignited and quickly produces a controlled fire and begins to impinge on the cladding

7. Peak Fire Exposure – The fire develops to maximum intensity, assessing vertical and lateral fire spread and system performance

8. Post-Test Condition – Cladding system integrity observed after fire extinguished over a monitoring period.

Understanding Rainscreen Cladding Fire Classification Ratings

THESE MATERIALS ARE AVAILABLE IN OUR RANGE OF RAINSCREEN SYSTEMS. YOU SHOULD REVIEW THE PRODUCT MANUFACTURES OWN DATASHEET FOR UP TO DATE INFORMATION.

A1 NON-COMBUSTIBLE |

A2 – LIMITED COMBUSTIBILITY |

|---|---|

ALPOLIC A1 |

ALPOLIC A2 |

ANODISED ALUMINIUM |

PPC ALUMINIUM |

CORTEN STEEL |

ALUCOBOND A2 |

COPPER |

LARSON A2 |

PRE-PAINT ALUMINIUM |

|

STAINLESS STEEL |

|

ZINC |

The classification is split into three parts, the main classification, the smoke classification and the flaming droplet classification.

The main part of the classification is its letter – A1, A2, B, C, D, E and F. A1 (Non-combustible) is the highest level of performance, with F the lowest performance level (No performance determined).

Products classified in A1 and A2 classes are non-combustible materials and from B to F are combustible materials in ascending order.

There is a smoke classification of s1, s2 or s3. s1 is the highest level of performance and s3 is the lowest performance level. There are no smoke requirements for Class E products.

There is a classification of flaming droplets of d0, d1 or d2. d0 is the highest level of performance and d2 is the lowest performance level.

BS EN 13501-1 provides the reaction to fire classification procedure for all construction products, including products incorporated within building elements. Products are considered in relation to their end use application.

The Sotech Learning Zone

Our dedicated Learning Zone is designed to bring architects, designers, contractors, and installers together to explore rainscreen cladding in a practical, hands-on environment.

Here, we host design workshops, CPD seminars, and launch events where projects can be evaluated, technical challenges addressed, and new ideas brought to life at the very start of the design process.

Alongside our modern meeting space, visitors can also experience a factory the journey from design to manufacture, gaining a deeper understanding of how our systems are constructed.

No downloads in list yet.

No downloads in list yet.